Low-voltage universal circuit breaker interrupter

A universal circuit breaker technology, applied in the direction of circuits, electrical components, electric switches, etc., can solve the problems of small effective area of arc extinguishing grids, affecting the breaking performance of circuit breakers, affecting the absorption of arc heat, etc., to improve the cooling effect, Simple structure and good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

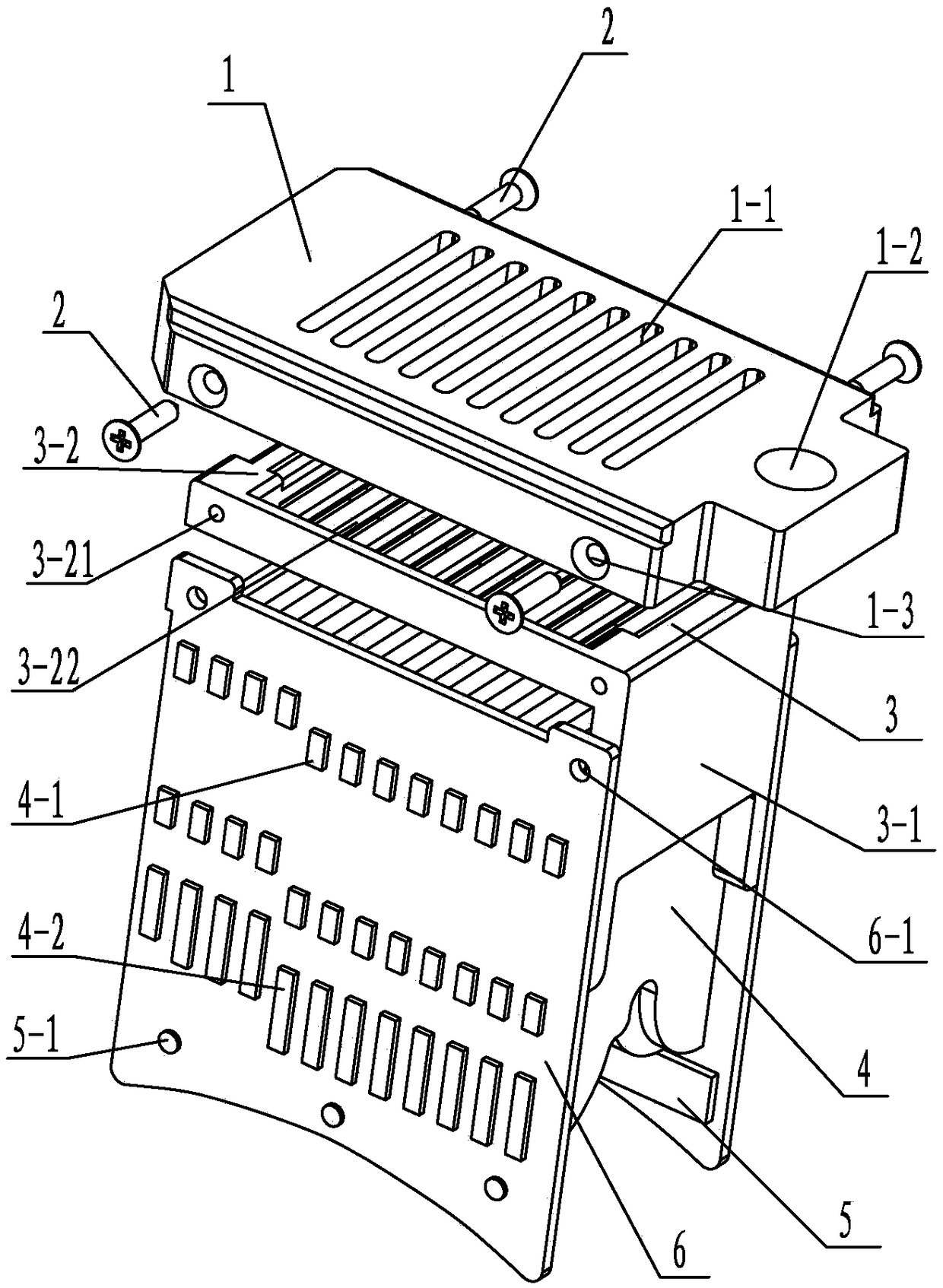

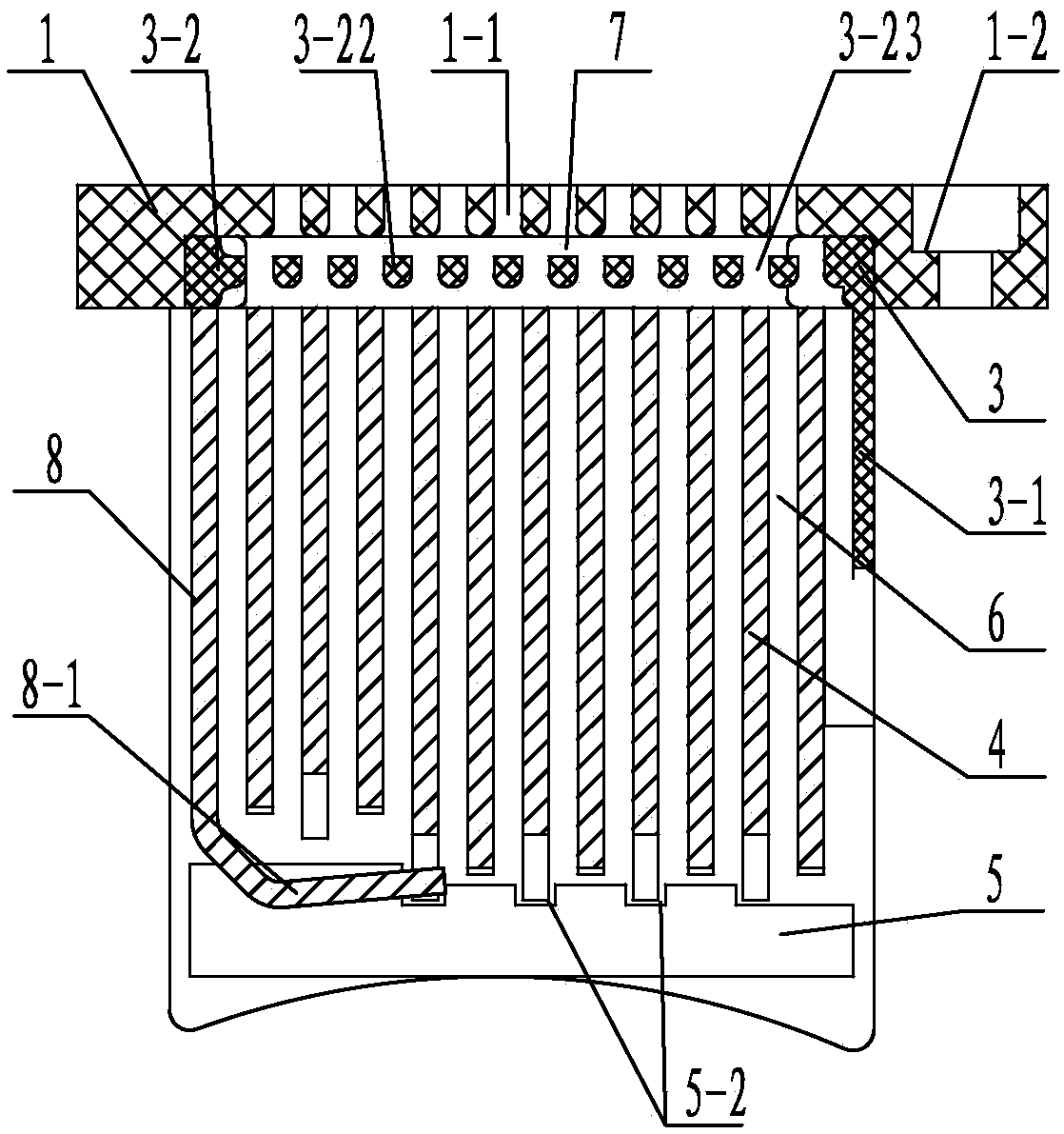

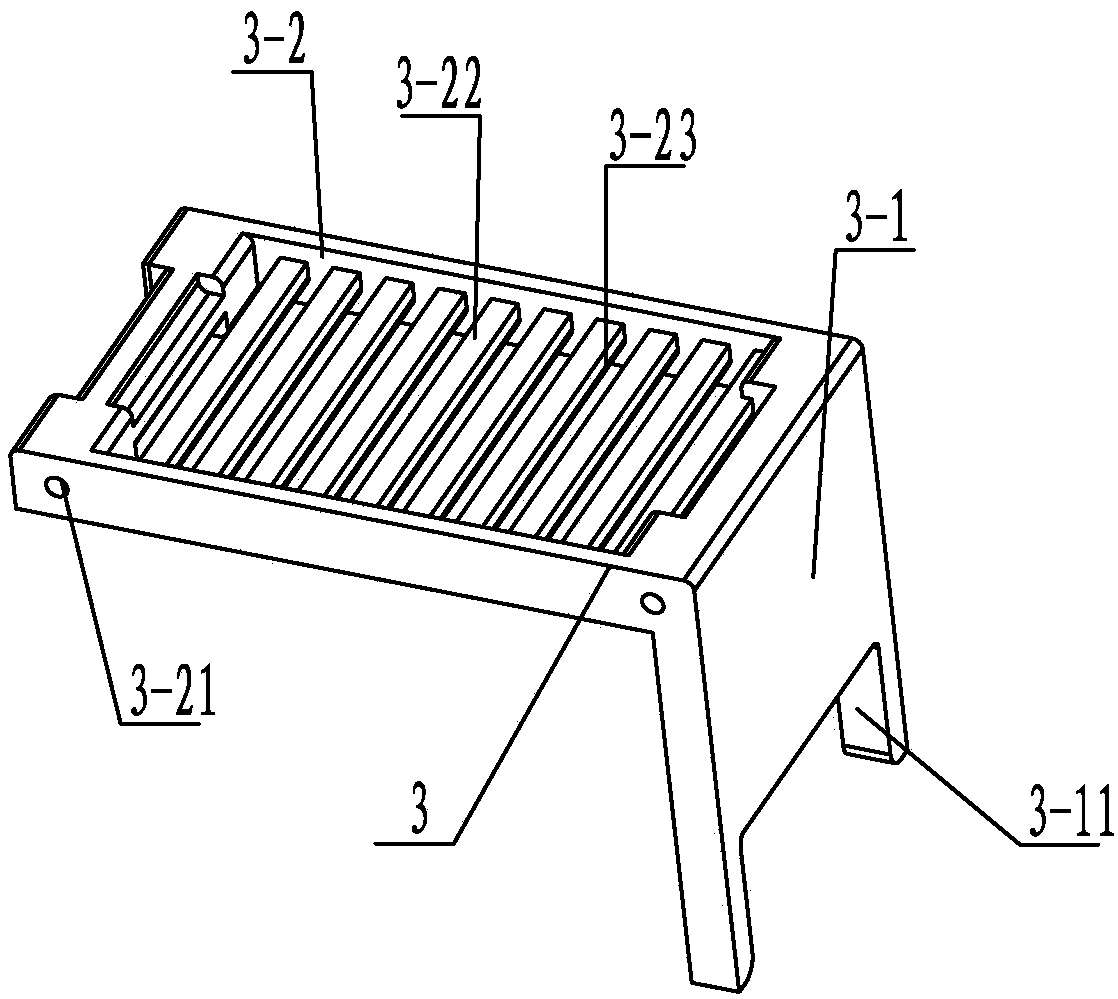

[0023] See Figure 1~5 As shown, the arc extinguishing chamber of the low-voltage universal circuit breaker of the present invention includes a cover plate 1 and an arc extinguishing grid 4 assembly. See figure 1 , 2 As shown, the cover plate 1 made of molding compound of the present invention is provided with a plurality of upper exhaust slots 1-1 parallel to and spaced apart from the arc extinguishing grid sheet 4, and the upper exhaust slots 1-1 are two The end is arc-shaped, and the arc-extinguishing fence 3 is installed in the concave installation groove at the bottom of the cover plate 1, see Figure 1~3 As shown, the arc extinguishing grid 3 made of molding compound in the present invention includes a square-shaped upper frame 3-2 and side baffles 3-1, and the upper frame 3-2 is provided with arc extinguishing grids 4 parallel to and spaced from A plurality of grid bars 3-22 are set, the lower exhaust slots 3-23 between two adjacent grid bars 3-22 are arranged alter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com