Dust-proof, antifouling and anti-static HDI flexible circuit board and processing technology thereof

A flexible circuit board, anti-static technology, used in flexible printed circuit boards, circuit devices, printed circuit components, etc., can solve the problem of breakdown of circuit chips on FPC boards, unstable electrostatic discharge, and can not play a protective role at any time and other problems to achieve the effect of solving static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

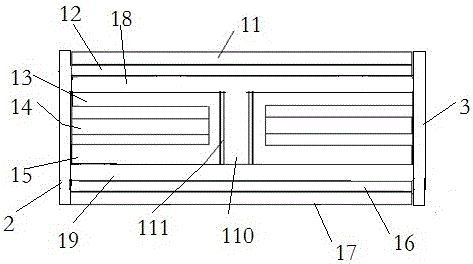

[0019] Such as figure 1 A dust-proof, anti-fouling and anti-static HDI flexible circuit board is shown, a circuit board body 1, one end of the circuit board body 1 is a connection port 2, and the other end is a golden finger 3, and the circuit board body 1 includes: a first Antistatic PET protective film 11, first cover film 12, first conductive layer 13, substrate 14, second conductive layer 15 and second cover film 16, second antistatic PET protective film 17, wherein the substrate 14 is located in the middle of the circuit board body 1, the first conductive layer 13 and the second conductive layer 15 are respectively bonded to the upper and lower sides of the base material 14 by transparent glue, the first conductive layer 13 has a first sinker, copper plating 18, and the second First sinking, copper plating 18 is provided with first covering film 12, first antistatic PET protection film 11 is arranged on the top of first covering film 12, second conductive layer 15 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com