Preparation method of fried gardenia formula granules

A technology of formula granules and stir-fried gardenia, applied in pharmaceutical formulas, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. Inconsistency and other problems, to achieve the effect of improving product yield and production efficiency, ensuring product quality, and solving static electricity and agglomeration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A preparation method of fried gardenia formula granules, characterized in that it comprises:

[0021] Extraction and concentration steps: take fried gardenia decoction pieces, add water to extract and decoct, and obtain the extract after filtration; concentrate the extract under reduced pressure to obtain a concentrate; the concentration temperature is 75-85°C, and the relative density of the concentrate is 1.00-1.02 ;

[0022] Spray-drying step: heating the concentrated solution, stirring evenly, and then spray-drying to obtain fried gardenia spray-dried powder;

[0023] Dry granulation step: first add silicon dioxide to the spray-dried powder of fried gardenia, the amount of silicon dioxide added is 0.5% of the weight of the spray-dried powder of fried gardenia, and after mixing evenly, dry granulation is carried out to obtain fried gardenia Subrecipe particles.

[0024] As a preferred embodiment, in the extraction and concentration step, the amount of water added i...

Embodiment 1

[0035] A preparation method of fried gardenia formula granules, comprising:

[0036] Extraction and concentration steps: Take 100kg of fried gardenia decoction pieces, add water 9 times the weight of the fried gardenia decoction pieces, control the extraction temperature at 98°C, extract and decoct for 1 hour, filter the extract; control the concentration temperature at 80°C, and concentrate under reduced pressure to relative Concentrate with a density of 1.01;

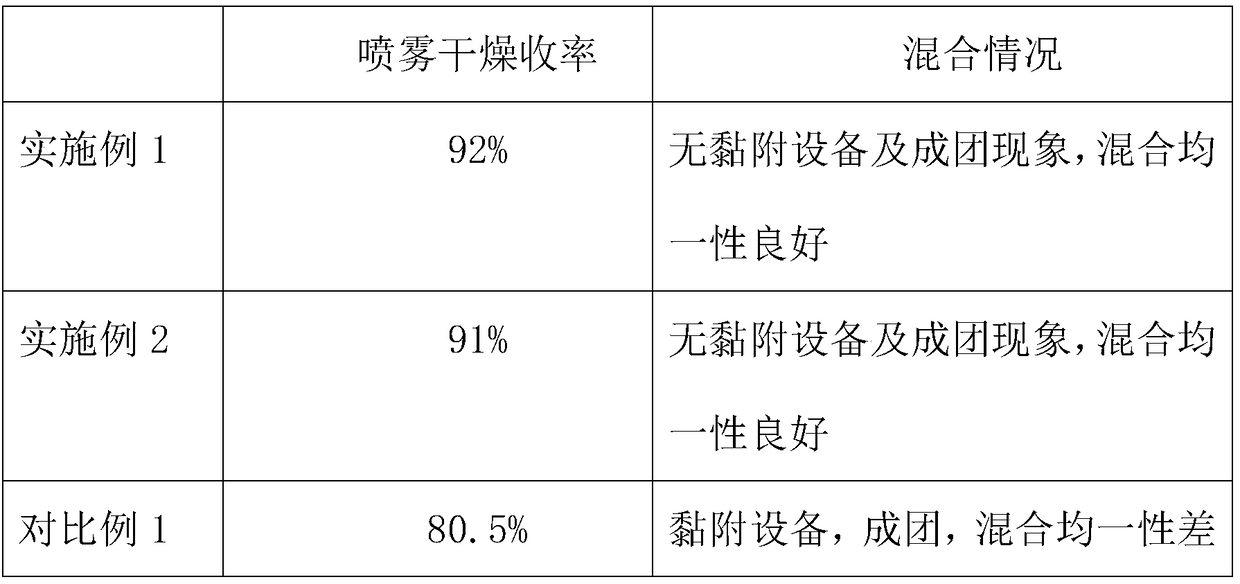

[0037] Spray drying step: heat the concentrated solution to 80°C, stir well, and control the spray drying parameters: air inlet temperature 175°C, temperature inside the tower 92°C, blast frequency 40Hz, induced wind frequency 45Hz, atomization frequency 40Hz, material delivery temperature 50 ℃, the concentrated solution was kept at a temperature of 80 ℃, and spray-dried to obtain 20 kg of fried gardenia spray-dried powder, with a yield of 92%; (%)=actual dry powder weight (g) / theoretical dry powder weight×100%);

...

Embodiment 2

[0040] A preparation method of fried gardenia formula granules, comprising:

[0041] Extraction and concentration steps: Take 100kg of fried gardenia decoction pieces, add water 9 times the weight of the fried gardenia decoction pieces, control the extraction temperature at 100°C, extract and decoct for 1 hour, filter the extract; control the concentration temperature at 85°C, and concentrate under reduced pressure to relative Concentrate with a density of 1.02;

[0042] Spray drying step: heat the concentrated solution to 80°C, stir well, and control the spray drying parameters: air inlet temperature 180°C, temperature inside the tower 95°C, blast frequency 45Hz, induced wind frequency 50Hz, atomization frequency 45Hz, feeding temperature 60 ℃, concentrated solution holding temperature 85 ℃, carry out spray drying to obtain 19.5kg of fried gardenia spray-dried powder, yield is 91%; (note: theoretical spray-dried powder weight=concentrated solution weight×concentrated solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com