Storage battery positive pole plate and manufacturing method thereof

A manufacturing method and positive plate technology, which is applied in the direction of lead-acid battery electrodes, battery electrodes, electrode carriers/collectors, etc., can solve the problems of short circuit of positive and negative plates, battery scrapping, and affecting the use effect of batteries, so as to avoid positive and negative Plate short circuit, prolonging the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

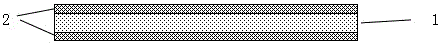

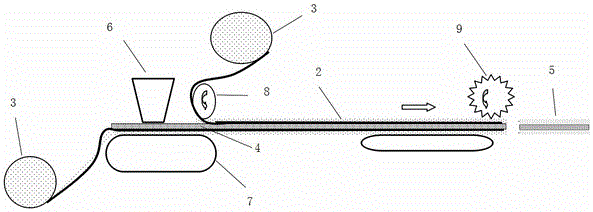

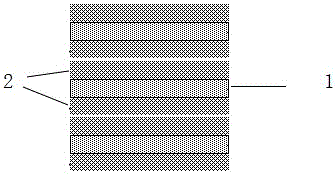

[0034] figure 1 As shown, the positive plate of the present invention includes a plate body 1 and a glass fiber felt layer 2 on the surface of the plate body 1 . The glass fiber mat layer on the surface of the board acts as a semi-permeable membrane. During use, the electrolyte can freely pass through the glass fiber mat layer, while the active material cannot pass through the glass fiber mat layer.

[0035] There are generally two traditional surface treatment methods for positive plates: surface acid washing and coated paper, but the coated paper will dissolve when it encounters the electrolyte. During the use of the battery, the active material on the positive electrode plate that is treated with acid or coated with cardboard will fall off from the plate after long-term charge and discharge. Since there is no protective measure on the plate, the active material that falls off will remain in the battery. The accumulation between the positive and negative plates will cause ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com