Red-cooked chicken production line manufacturing and production system

A production system and assembly line technology, which can be used in slaughtering, poultry viscera removal devices, poultry processing, etc., can solve problems such as high cost and low production efficiency, reduce production costs, improve production efficiency, and be conducive to environmental and sanitation control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

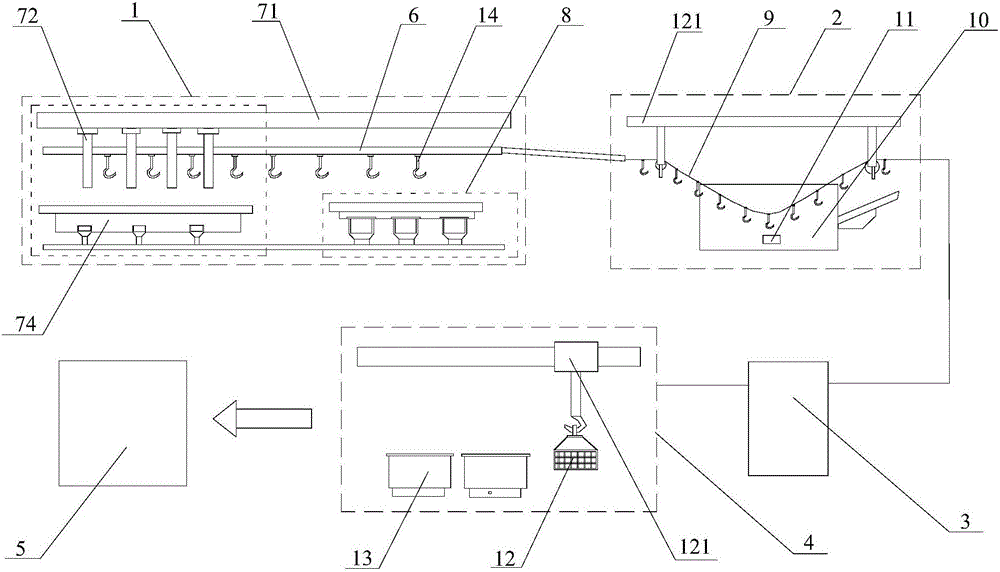

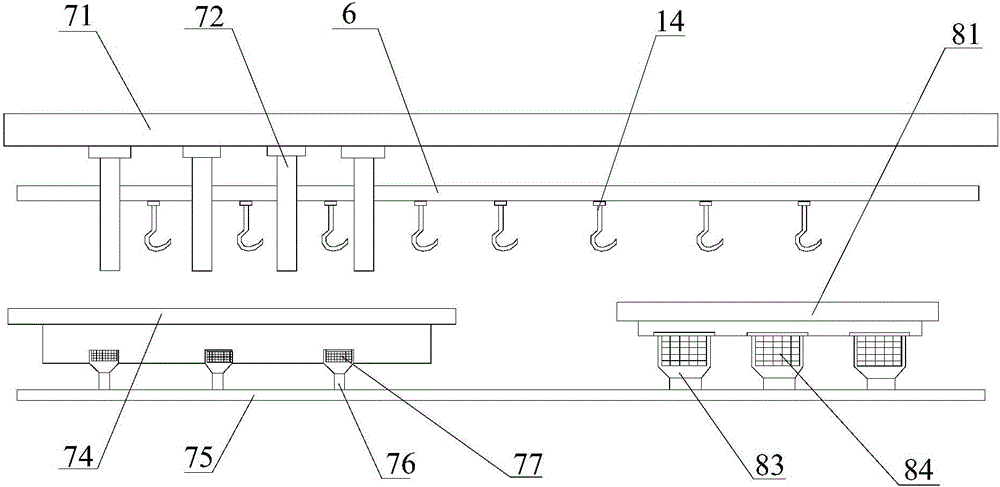

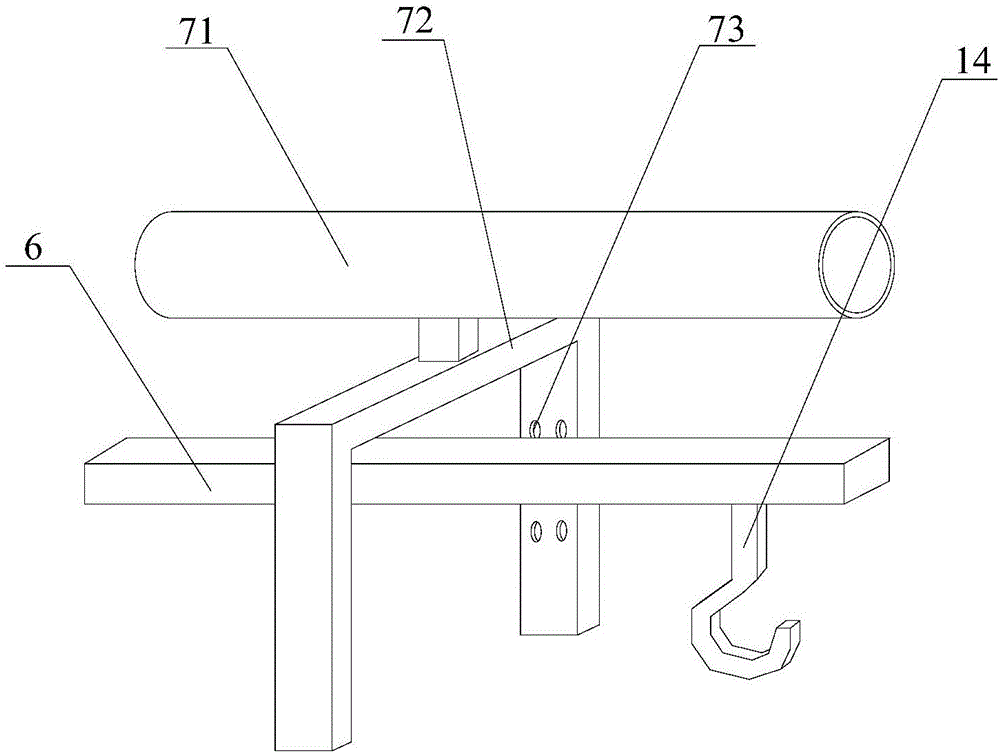

[0022] Such as figure 1 As shown, a Fuliji roasted chicken assembly line production system includes slaughtering section (not shown in the figure), cleaning section 1, sugar spraying section 2, frying section 3, marinating section 4, and vacuum packaging section 5 according to the production process. , the cleaning section 1 is composed of a rotary chain transmission track 6 and a spray device 7 and a cleaning device 8 arranged on the rotary chain transmission track 6; the sugar spraying section 2 includes a one-way chain transmission track 9 and the liquid spray tank 10 arranged under the one-way chain transmission track 9, the sugar solution nozzle 11 is arranged in the liquid spray tank 10, the input end of the one-way chain transmission track 9 is connected to the return The output end of the transformation chain transmission track 6 is connected, and the output end of the one-way chain transmission track 9 is connected in series with the frying section 3 in sequence, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com