Method for denitrifying SNCR flue gas

A denitration and flue gas technology, applied in the field of SNCR flue gas denitration, can solve the problems of increased ammonia escape, adverse effects on efficiency and economy, large consumption of reducing agent, etc., achieving favorable efficiency and economy, and stable denitration efficiency. , the effect of reducing the consumption of reducing agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

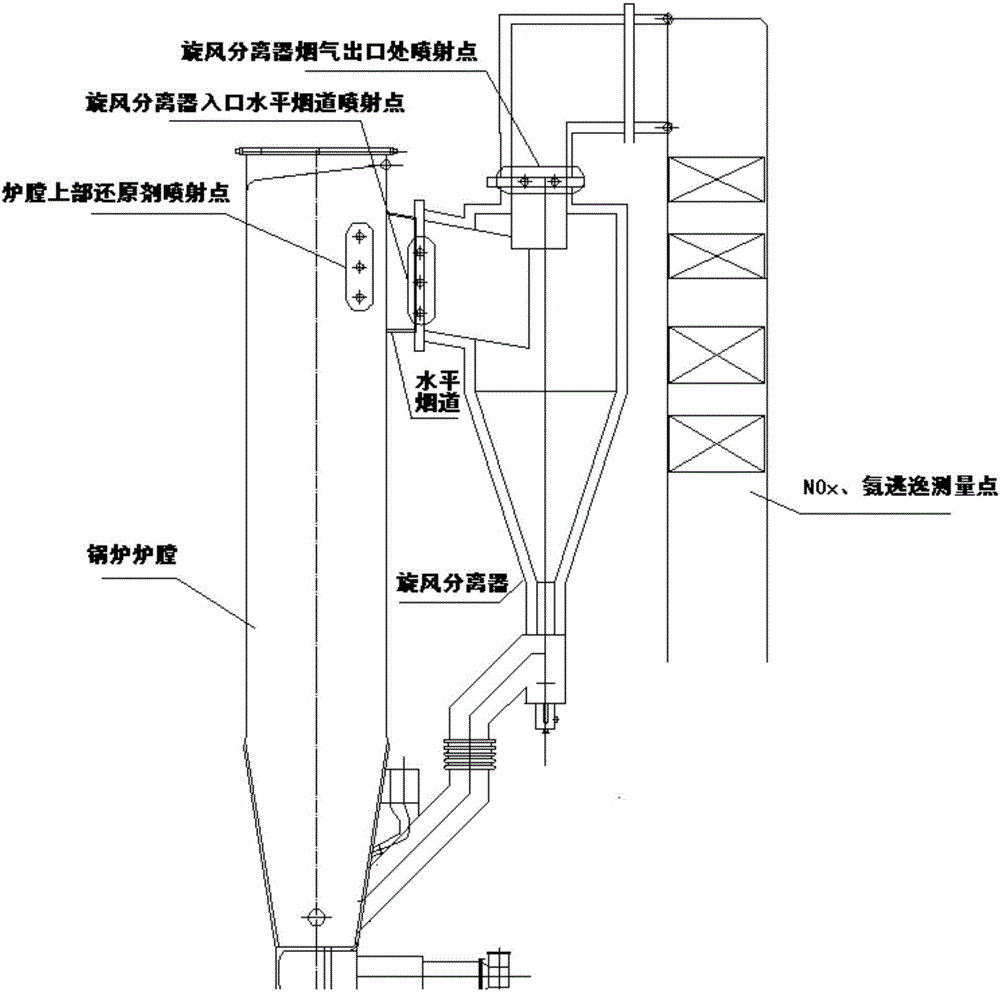

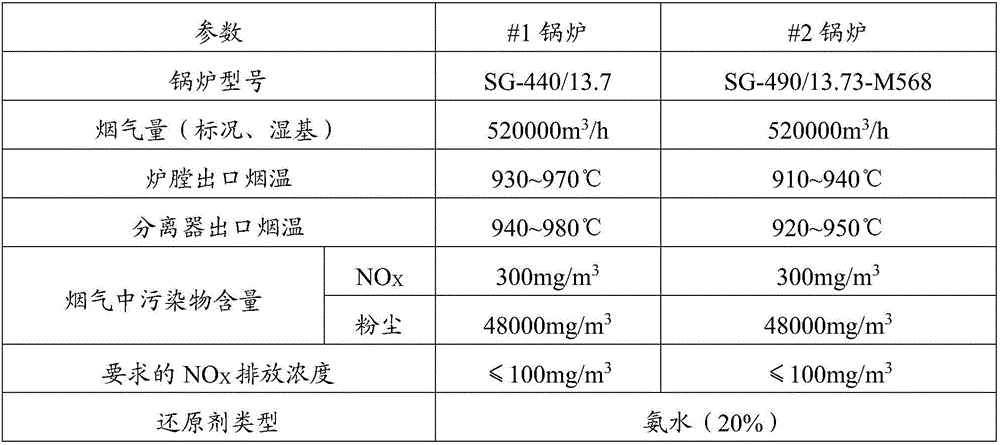

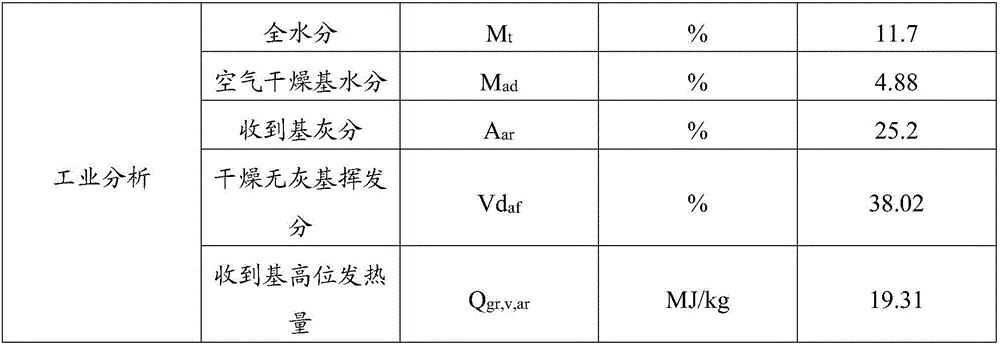

[0033] In this example, the flue gas denitrification devices of No. 1 and No. 2 combined heat and power generating units are used. No. 1 unit is equipped with a 440t / h circulating fluidized bed boiler (#1 boiler), and No. 2 unit is equipped with a 490t / h circulating fluidized bed boiler (# 2 boiler or 2# boiler); such as figure 1 The shown flue gas denitrification device adopts SNCR process for denitrification. The main design conditions are shown in Table 1, and Table 1 is the denitrification design condition parameters. The field test started on April 27, 2016 and ended on April 29, 2016. The characteristics of the fuel used during the test are shown in Table 2, and Table 2 is the analysis result of the coal quality.

[0034] Table 1 Design condition parameters of denitrification

[0035]

[0036] Table 2 Analysis results of coal quality for combustion

[0037]

[0038]

[0039] 1. If figure 1 As shown, three groups of reducing agent injection points are set on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com