Control method of marine SCR (selective catalytic reduction) system

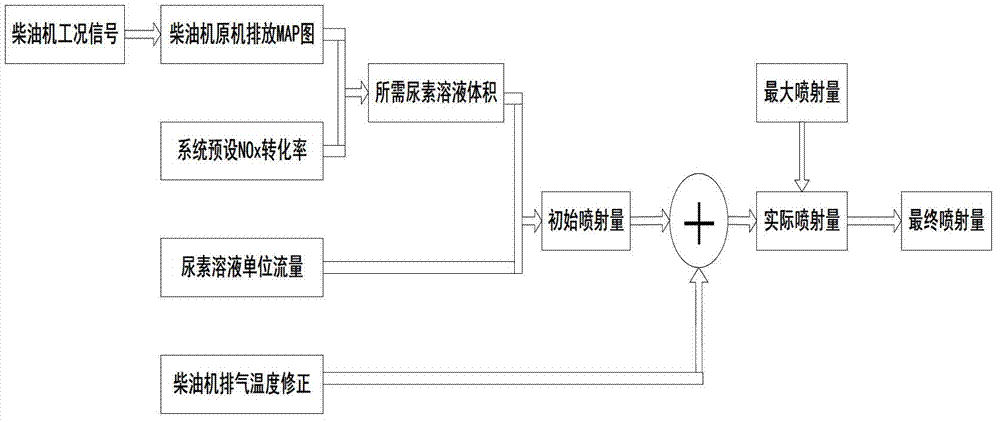

A technology of SCR system and control method, which is applied to the electric control of exhaust treatment devices, exhaust treatment, mechanical equipment, etc., and can solve the problems of poor real-time performance and dynamic stability, drift of NOx conversion rate, low anti-interference ability, etc. , to achieve the effect of convenient application maintenance, superior stability and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

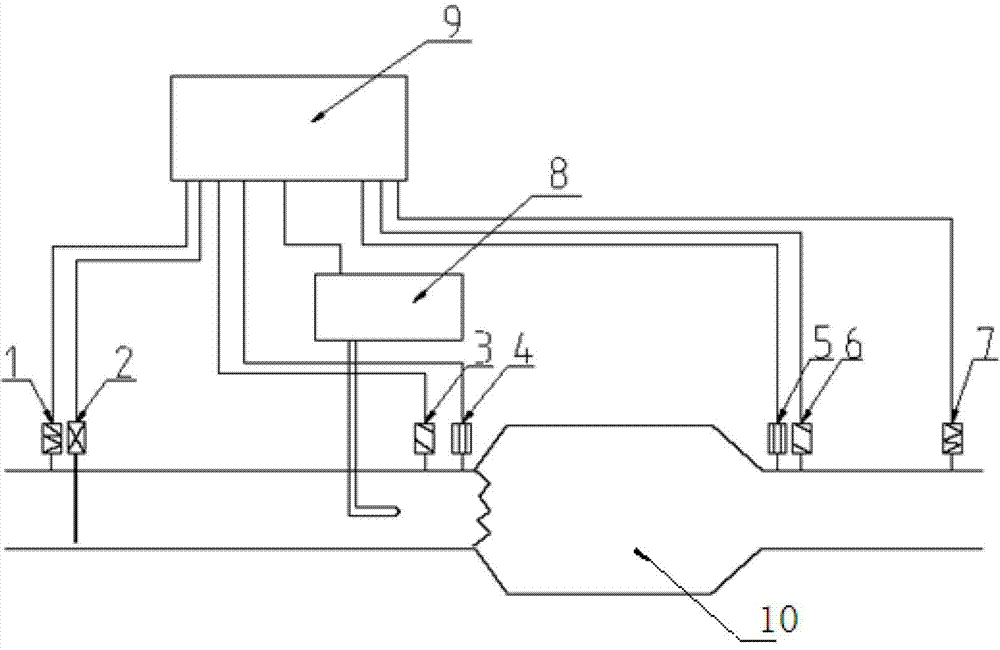

[0029] See attached figure 2 , 3 , a control method for a marine SCR system, which is based on the SCR system. The layout of the SCR system is as follows: on the exhaust pipe in front of the SCR catalyst 10, a temperature sensor A1, an exhaust flow mass sensor 2, an injection device 8, A pressure sensor A3 and a nitrogen oxide sensor A4, a nitrogen oxide sensor B5, a pressure sensor B6 and a temperature sensor B7 are arranged in sequence on the exhaust pipe behind the SCR catalyst 10;

[0030] Connect the temperature sensor A1, the exhaust flow mass sensor 2, the injection device 8, the pressure sensor A3, the nitrogen oxide sensor A4, the nitrogen oxide sensor B5, the pressure sensor B6 and the temperature sensor B7 to the PID controller 9 respectively;

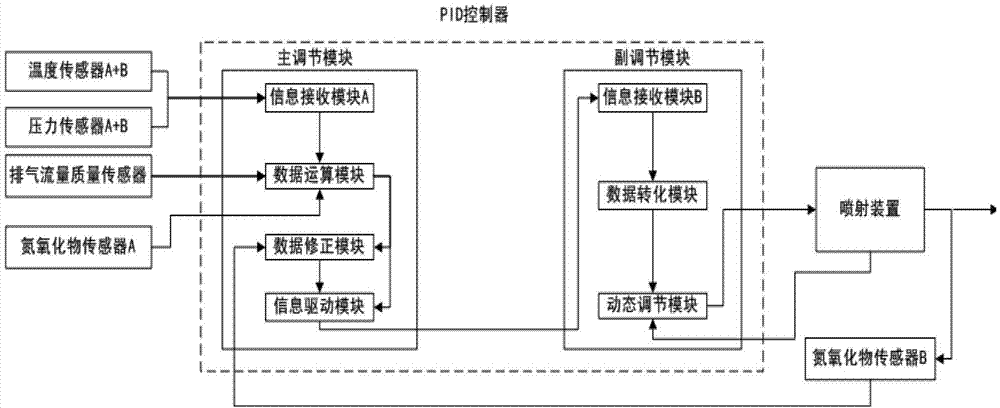

[0031] The PID controller 9 is set, and the main adjustment module and the auxiliary adjustment module are set in the PID controller 9; wherein, the main adjustment module includes an information receiving module A, a data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com