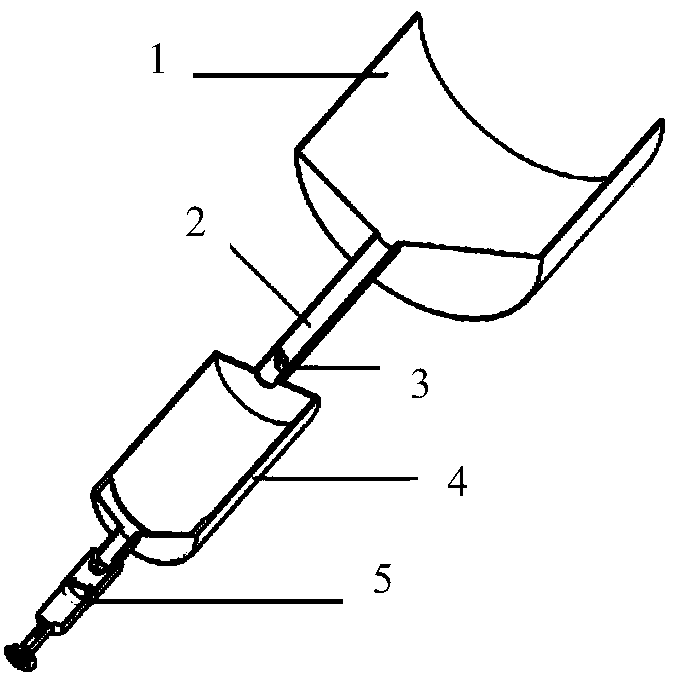

Device for melting and quantitatively spraying solid urea

A technology of solid urea and urea injection, applied in the field of denitrification, can solve the problems of difficult storage, energy consumption, easy to freeze, etc., and achieve the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

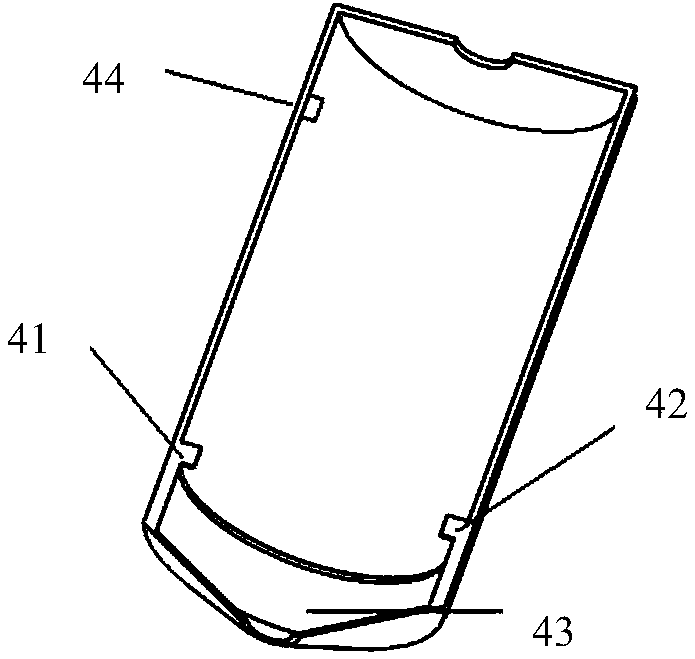

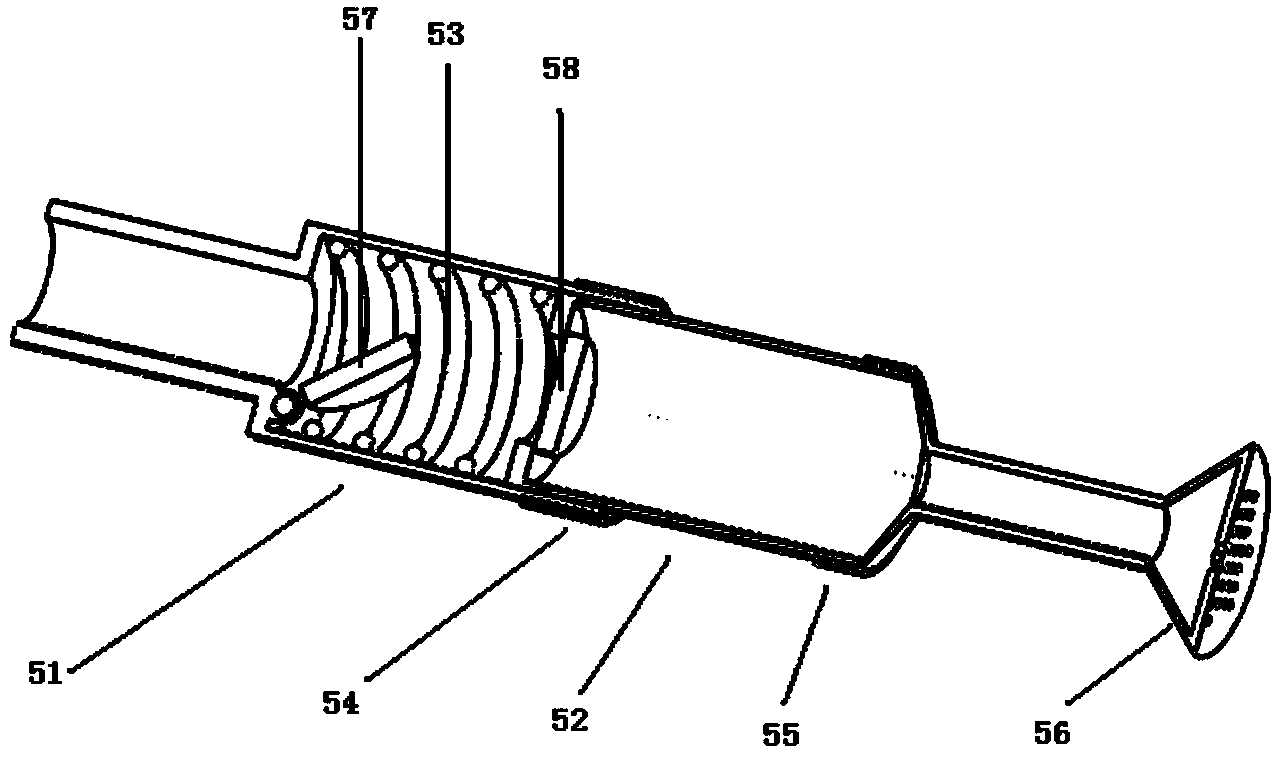

[0023] see Figure 5 and combine Figure 4, which shows a scheme of the device according to the present invention. In this scheme, the device for melting solid urea and injecting quantitatively according to the present invention is installed on the SCR processor located in the exhaust gas pipeline. In this embodiment, the volume of the urea storage tank 1 is 10 L, and the volume of the urea melting tank 4 is 300 ml. When the exhaust gas starts to be discharged, the sensor (electrochemical gas sensor can be selected, with an accuracy of 1ppm, which belongs to the electrical signal sensor, and the model can be selected as A-21 gas sensor, and the manufacturer is Shanghai Senchuang Electronic Technology Development Co., Ltd.) collects the exhaust signal, and Send the tail gas signal to the ECU, and the ECU then sends an instruction to the heating device 43 of the melting tank, and the heating device 43 starts heating, and at the same time, the temperature sensor 42 (a commonly u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com