Circulating fluidized bed flue gas desulfurization apparatus

A technology of circulating fluidized bed and desulfurization device is applied in the field of flue gas purification, which can solve the problems of increasing the operation and maintenance cost of the device, easy blockage, and large resistance reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

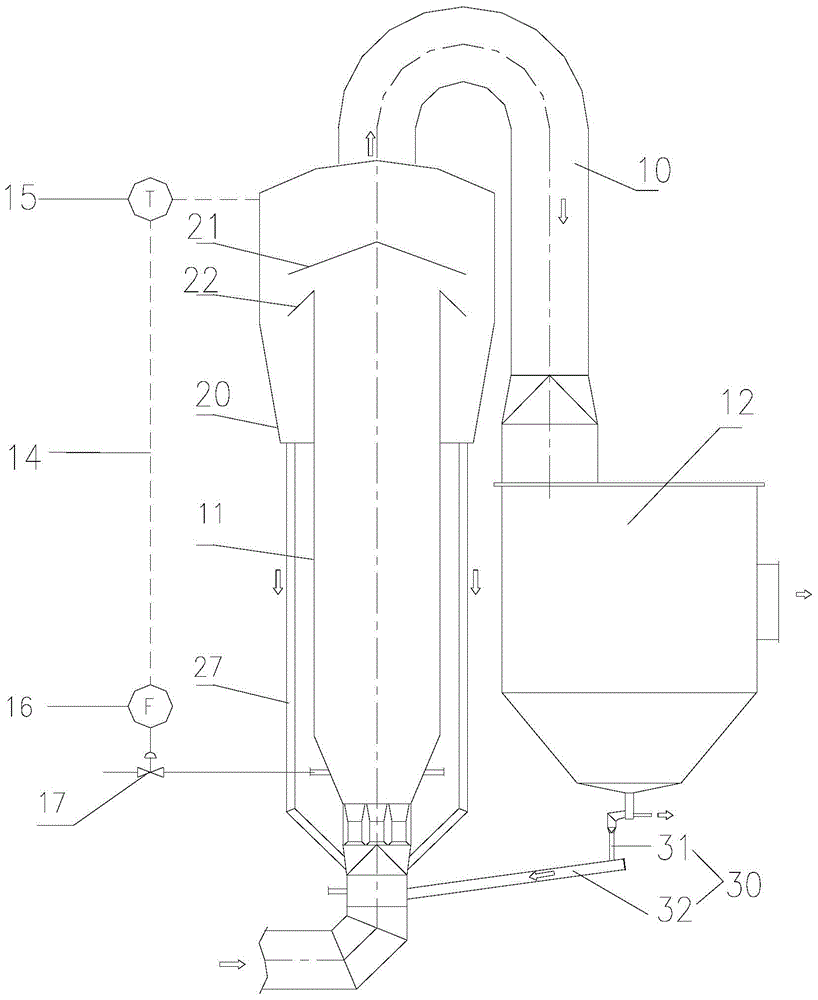

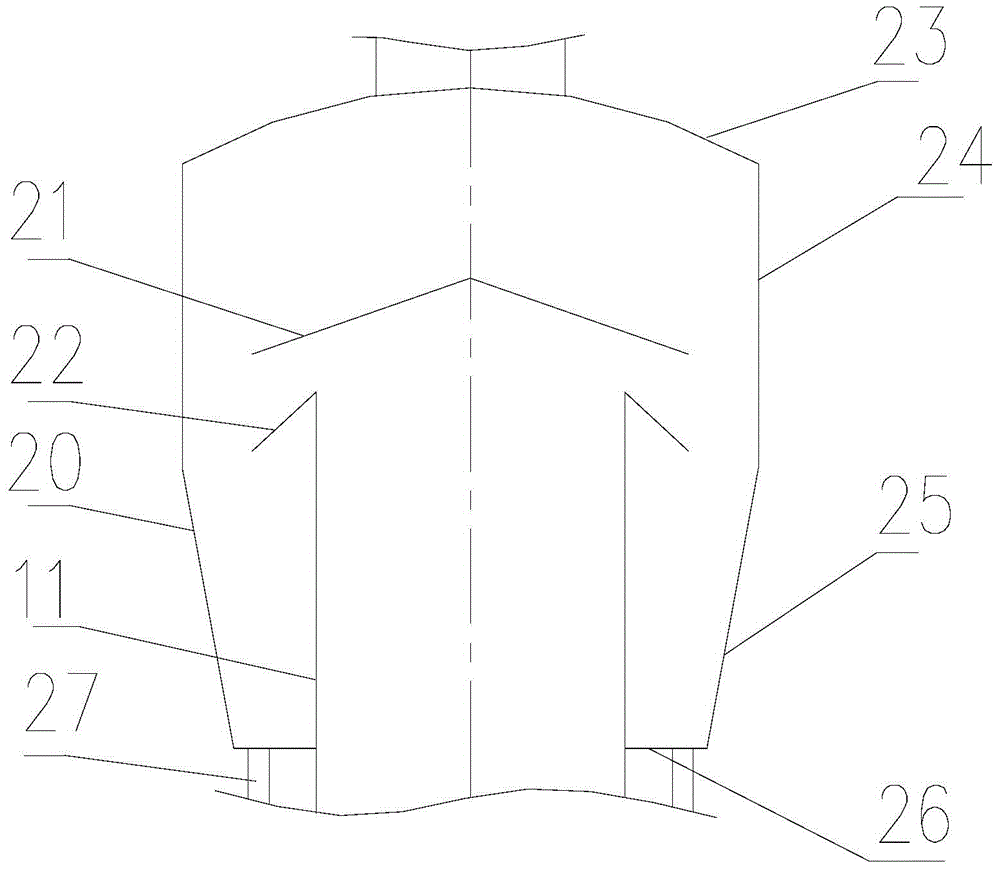

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0030] In the present invention, in the absence of a contrary statement, the orientation words used such as "upper, lower," are based on the flow direction of the flue gas in the reaction tower when the circulating fluidized bed flue gas desulfurization device works normally. Specifically, the flow direction towards the smoke is up, and the direction away from the flow of the smoke is down. "Inside and outside" refer to the inside and outside of the corresponding component contours. In addition, the arrow directions in the drawings represent the smoke direction of flow.

[0031] Such as Figure 1 to Figure 2 As shown, the present invention provides a circulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com