Ultrafiltration membrane assembly of porous water inlet pipe

A water inlet pipe, ultrafiltration membrane technology, applied in ultrafiltration, membrane technology, semi-permeable membrane separation and other directions, can solve problems such as increased energy consumption, decreased water flux, pollution, etc., to reduce replacement costs and prolong use. Longevity, the effect of reducing the frequency of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

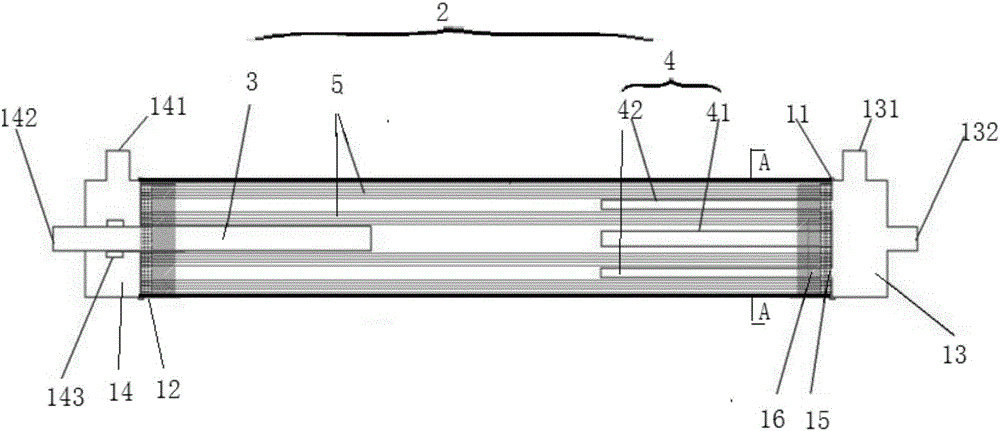

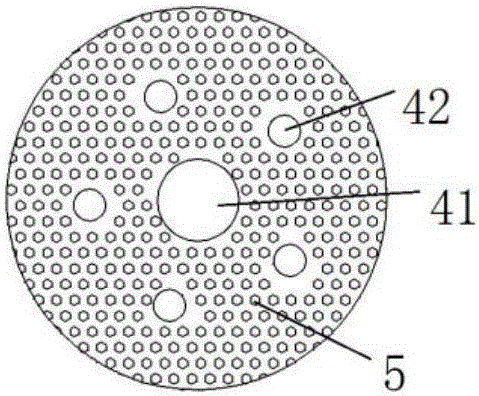

[0014] Such as figure 1 As shown, the ultrafiltration membrane assembly of the porous water inlet pipe in this embodiment includes a pressure-bearing housing 1 and an ultrafiltration membrane group 2 , and the ultrafiltration membrane group 2 is arranged in the pressure-bearing housing 1 . The ultrafiltration membrane group 2 specifically includes an outlet pipe 3 , an inlet pipe 4 and hollow fiber ultrafiltration membrane filaments 5 . The water inlet port 11 of the pressure-bearing shell 1 is covered with a water inlet end cover 13, and the water outlet port 12 is covered with a water outlet end cover 14. The water inlet end cover 13 is provided with a raw water inlet and an aeration device 132, and the water outlet end cover 14 is provided with a clean water outlet 141 and a concentrated water outlet 142, and the concentrated water outlet 142 is connected to the outlet pipe 3 through a pipeline. During specific implementation, the water inlet end cover 13 and the water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com