Multifunctional analysis high-pressure reaction kettle and application method thereof

A high-pressure reaction kettle and multi-functional technology, which is applied in the field of multi-functional analysis high-pressure reaction kettles, can solve problems such as low efficiency and limit the leaching rate of pressure leaching reaction, and achieve the effect of high heat utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

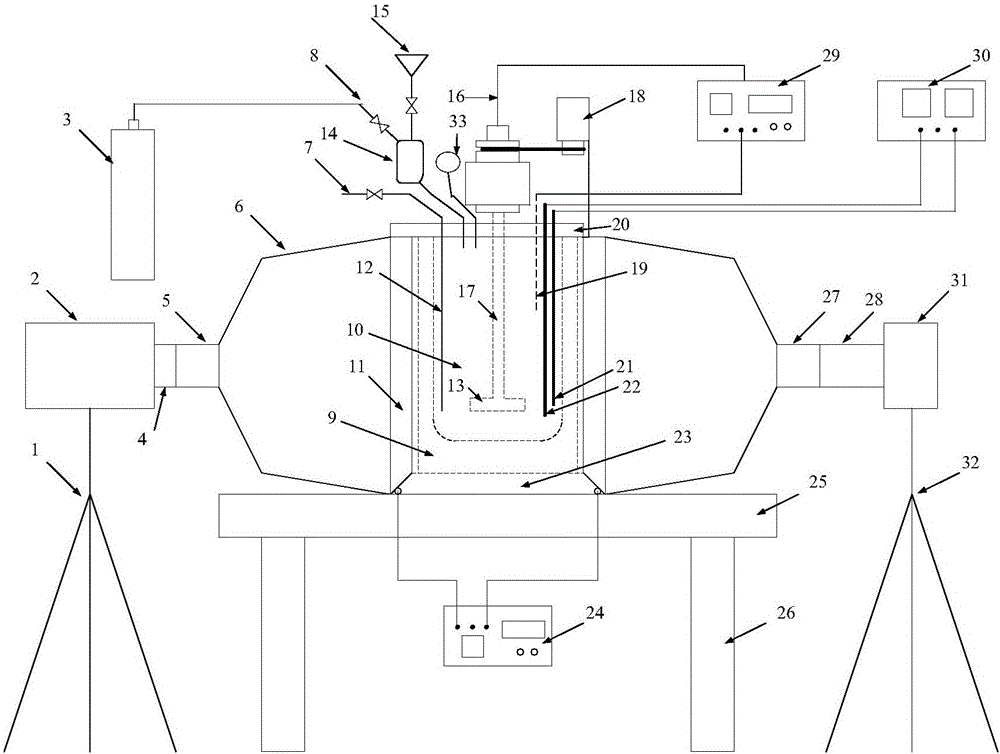

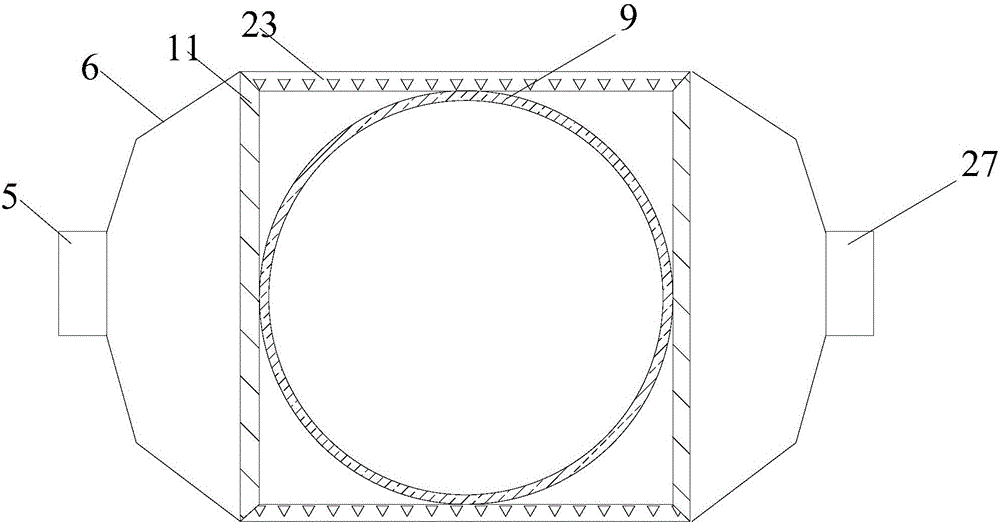

[0069] A multi-functional analytical high-pressure reactor, its structure schematic diagram is as follows figure 1 As shown, its top-view cross-sectional schematic diagram is shown in figure 2 As shown, including autoclave, anti-microwave protection cover 6, camera device, lighting device and potential measuring device;

[0070] In the described autoclave structure, the kettle body is a transparent kettle body 9, the kettle lid is an anti-microwave kettle lid 20, and the heating equipment is a microwave heater 23;

[0071] Microwave heater 23 is arranged on the front and back both sides of transparent kettle body 9; Anti-microwave protective cover 6 is arranged on the outside of autoclave, and is left and right sides, and camera device is arranged on the outside of anti-microwave protective cover 6, and is connected with anti-microwave The protective cover 6 is connected; the lighting device is arranged on the outside of the microwave-proof protective cover 6, opposite to th...

Embodiment 2

[0106] A multi-functional analytical high-pressure reactor, its structure schematic diagram is as follows figure 1 As shown, its top-view cross-sectional schematic diagram is shown in figure 2 As shown, including autoclave, anti-microwave protection cover 6, camera device, lighting device and potential measuring device;

[0107] In the described autoclave structure, the kettle body is a transparent kettle body 9, the kettle lid is an anti-microwave kettle lid 20, and the heating equipment is a microwave heater 23;

[0108] Microwave heater 23 is arranged on the front and back both sides of transparent kettle body 9; Anti-microwave protective cover 6 is arranged on the outside of autoclave, and is left and right sides, and camera device is arranged on the outside of anti-microwave protective cover 6, and is connected with anti-microwave The protective cover 6 is connected; the lighting device is arranged on the outside of the microwave-proof protective cover 6, opposite to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com