Motion control device and method for abrasive belt

A motion control device and abrasive belt technology, applied in application, grain processing, agriculture, etc., can solve the problems of difficult adjustment of photoelectric switches, false signals, poor stability, etc. The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

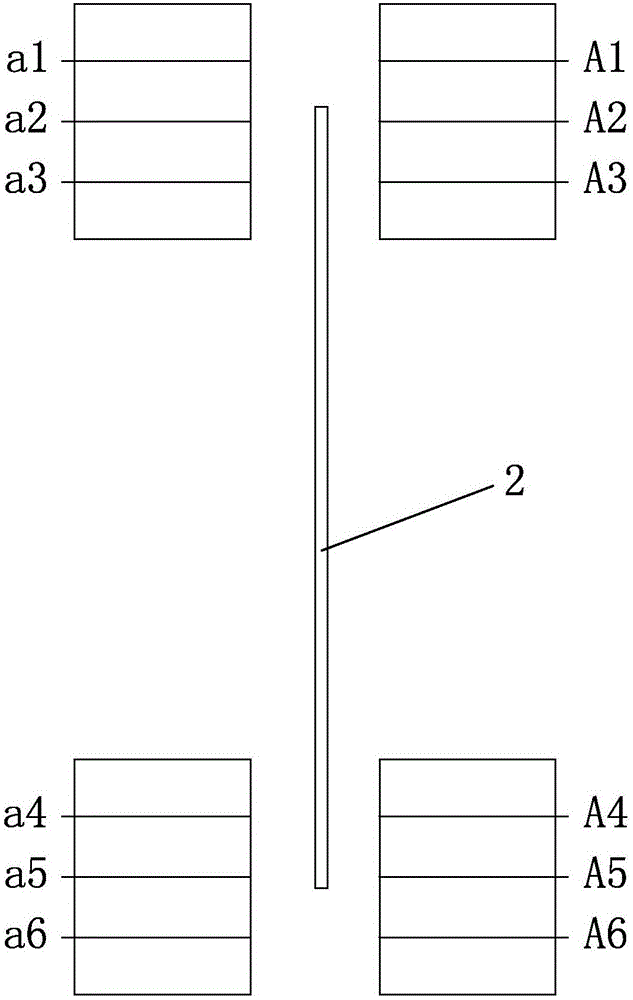

[0030] Such as figure 1 As shown, it is the control method of the abrasive belt in the prior art, A1, A2, A3, A4, A5, A6 send signals, a1, a2, a3, a4, a5, a6 receive signals, when the abrasive belt goes up to A2, the abrasive belt The belt goes down, when the abrasive belt goes down to A4, the abrasive belt goes up; when the abrasive belt goes up to A1, the equipment alarms and stops, when the abrasive belt goes down to A6, the equipment alarms and stops; when the abrasive belt goes up to A3 or the upper part of the belt is low At A3, the equipment alarms and shuts down. When the abrasive belt goes down to A4 or the lower part of the abrasive belt is lower than A4, the equipment alarms and shuts down. However, it is difficult to adjust the photoelectric switch in the process of controlling the up and down movement of the abrasive belt, and the photoelectric switch in the lower group is easily blocked by rice bran, giving false signals, making wrong operations, and poor stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com