Garbage processing method for small-size garbage compressor

A garbage compressor and garbage disposal technology, which is used in presses, grain processing, and solid waste removal. Efficient processing, less space and less labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with specific embodiment, preparation method of the present invention is described in further detail:

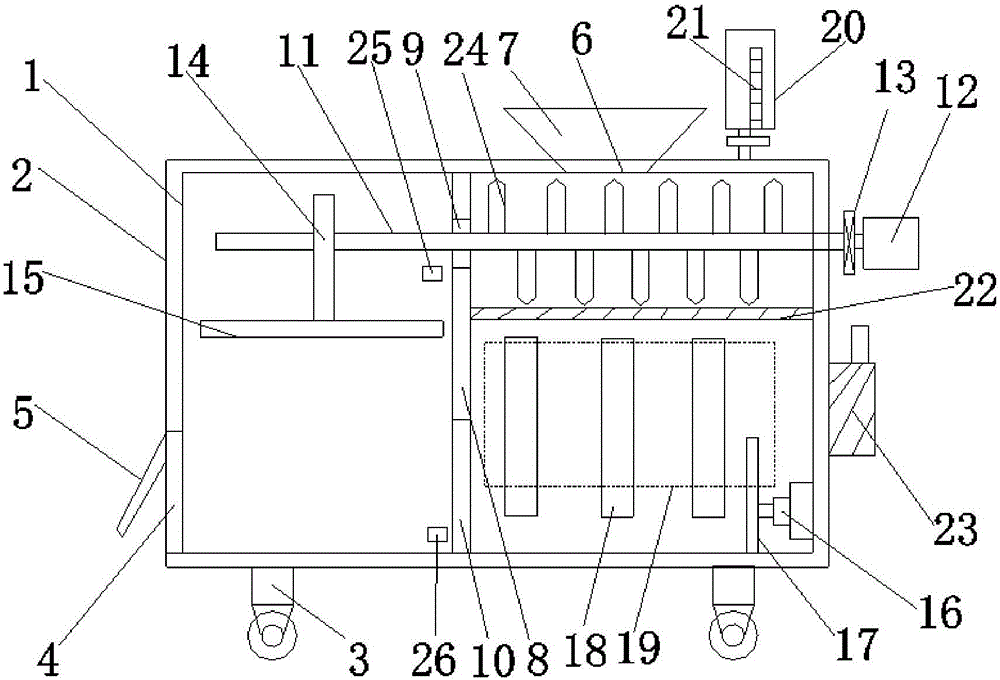

[0014] refer to figure 1 The shown small garbage compressor includes a housing 1, the outer side of the housing 1 is provided with a shock-proof and sound-insulating board 2, and the inside of the housing 1 is divided into a first working area and a second working area by a partition 8, The upper part of the housing 1 is provided with a transmission shaft 11 that runs through the partition 8 and the two working areas, the partition 8 is provided with a bearing seat 9 for supporting the transmission shaft 11, and one end of the transmission shaft 11 passes through the coupling. The shaft device 13 is connected with a motor 12, the part of the transmission shaft 11 located in the first working area is provided with several groups of crushing blades 24 along the radial direction, and the part of the transmission shaft 11 located in the second working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com