Multifunctional mixing device for raw materials of concentrated feed

A technology of concentrated feed and mixing device, which is applied in the direction of feed, mixer, mixer with rotating stirring device, etc. It can solve the problems of uncontrollable feeding amount of feed, affecting the proportion of mixing, and long storage time of feed, etc. Achieve the effect of perfect processing function, increase sealing performance and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

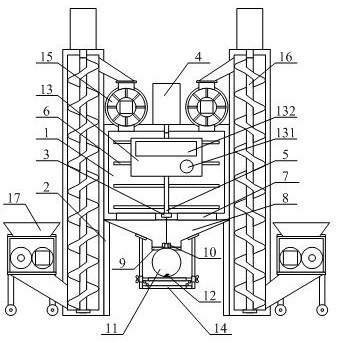

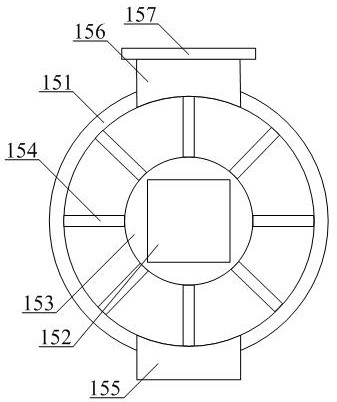

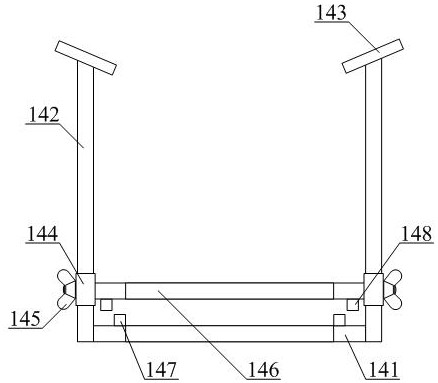

[0037] as attachedfigure 1 And attached figure 2 As shown, a multifunctional concentrated feed raw material mixing device includes a mixing box 1, a support leg 2, a bearing 3, a mixing motor 4, a main shaft 5, a mixing rod 6, a discharge port 7, a collection hopper 8, and a sealing gasket 9, Shaft plate 10, material blocking cover 11, connecting bolt 12, control box 13, packaging bag opening fixing frame structure 14, feed lowering amount controller structure 15, screw upper material cylinder structure 16 and movable block feed crushing box structure 17. The supporting legs 2 are respectively welded to the four corners of the lower part of the mixing box 1; the bearing 3 is embedded in the inner lower middle of the mixing box 1; the mixing motor 4 is bolted to the upper part of the mixing box 1 The middle position, and the output shaft runs through the inner upper middle position of the mixing box 1; the lower part of the main shaft 5 is interference-connected to the inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com