Casting technology for hub

A casting process and wheel hub technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of wheel hub fracture, bulldozer paralysis, quenching and tempering treatment, etc., so as to ensure the use performance and solve casting shrinkage and cracks The effect of quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, a casting process of a wheel hub includes the following steps:

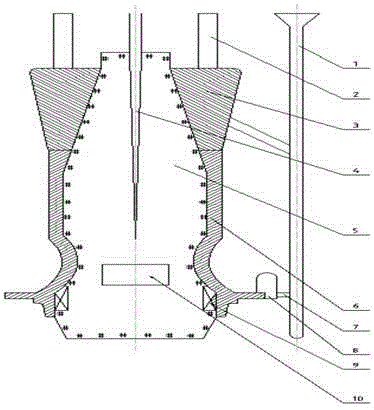

[0026] (1) Pattern design: the design of the hub casting system, 1 straight gate, size φ40mm; 1 horizontal gate, size 45×34×45(mm); 1 inner gate; size: 55×45× 40(mm); wheel hub sand core design: the air channel is set in the middle of the sand core, with a size of φ20mm; the middle and lower part of the sand core is equipped with an anti-crack hole, and the foam plastic gasification mold is placed in the core making, and the size is 60×90×90(mm); the wheel hub Riser and chiller design: 1 riser: φ285×φ330×200 (mm), 4 riser air passages are evenly distributed on the hub riser, with a size of φ50mm; 4 external chillers are evenly distributed on the hub flange In the end hole sand core.

[0027] (2) Sand mold making: modeling adopts sodium silicate sand CO2 method, 100 parts of quartz sand, clay sand, 3 parts of clay, 1 part of bentonite, 5 parts of asbestos powder, 1.5 parts of wood chips...

Embodiment 2

[0033] In this embodiment, a casting process of a wheel hub includes the following steps:

[0034] (1) Pattern design: the design of the hub casting system, 1 straight gate, size φ40mm; 1 horizontal gate, size 45×34×45(mm); 1 inner gate; size: 55×45× 40(mm); wheel hub sand core design: the air channel is set in the middle of the sand core, with a size of φ20mm; the middle and lower part of the sand core is equipped with an anti-crack hole, and the foam plastic gasification mold is placed in the core making, and the size is 60×90×90(mm); the wheel hub Riser and chiller design: 1 riser: φ285×φ330×200 (mm), 4 riser air passages are evenly distributed on the hub riser, with a size of φ50mm; 4 external chillers are evenly distributed on the hub flange In the end hole sand core.

[0035] (2) Sand mold making: modeling adopts sodium silicate sand CO2 method, 100 parts of quartz sand, clay sand, 5 parts of clay, 2 parts of bentonite, 5 parts of asbestos powder, 1.5 parts of wood chip...

Embodiment 3

[0041] In this embodiment, a casting process of a wheel hub includes the following steps:

[0042](1) Pattern design: the design of the hub casting system, 1 straight gate, size φ40mm; 1 horizontal gate, size 45×34×45(mm); 1 inner gate; size: 55×45× 40(mm); wheel hub sand core design: the air channel is set in the middle of the sand core, with a size of φ20mm; the middle and lower part of the sand core is equipped with an anti-crack hole, and the foam plastic gasification mold is placed in the core making, and the size is 60×90×90(mm); the wheel hub Riser and chiller design: 1 riser: φ285×φ330×200 (mm), 4 riser air passages are evenly distributed on the hub riser, with a size of φ50mm; 4 external chillers are evenly distributed on the hub flange In the end hole sand core.

[0043] (2) Sand mold making: modeling adopts sodium silicate sand CO2 method, 100 parts of quartz sand, clay sand, 6 parts of clay, 3 parts of bentonite, 5 parts of asbestos powder, 1.5 parts of wood chips...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com