Novel punching machine tool equipment

A technology of equipment and lathes, applied in the field of new punching lathe equipment, can solve the problems of low safety, high labor intensity of workers, low processing efficiency, etc., and achieve the effects of improving product quality, good processing effect and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

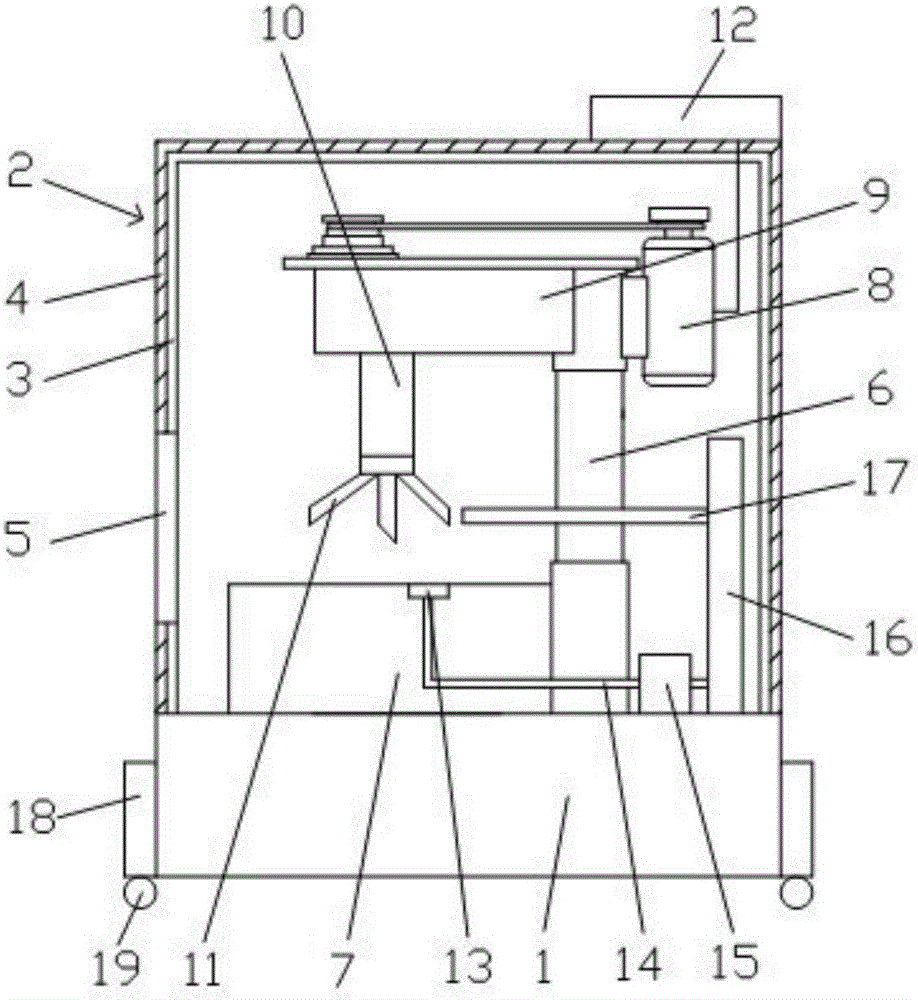

[0015] Such as figure 1 As shown, a new type of punching lathe equipment includes a base 1 and a protective cover 2, the protective cover 2 is located above the base 1, and the protective cover 2 is provided with two layers, from the outside to the inside are the sound insulation layer 4 and the The steel plate layer 3, the base 1 is provided with a workbench 7 and a pillar 6, the pillar 6 is provided with a motor 8, the motor 8 is connected with a solar panel 12 and a gearbox 9, and the bottom of the gearbox 9 is A rotating shaft 10 is provided, and a drill bit assembly 11 is arranged on the rotating shaft 10. A water outlet 13 is arranged on the workbench 7. A water pipe 14 is connected to the water outlet 13. A circulating pump 15 is arranged on the water pipe 14. The circulation pump 15 is connected with a refrigerating device 16, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com