Automatic assembling system and assembling method for combined cam shaft

An automatic assembly and camshaft technology, which is applied in the direction of measuring devices, instruments, torque measurement, etc., can solve the problems of cumbersome torque detection operation, inability to detect torque, inability to combine camshaft positioning torque detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

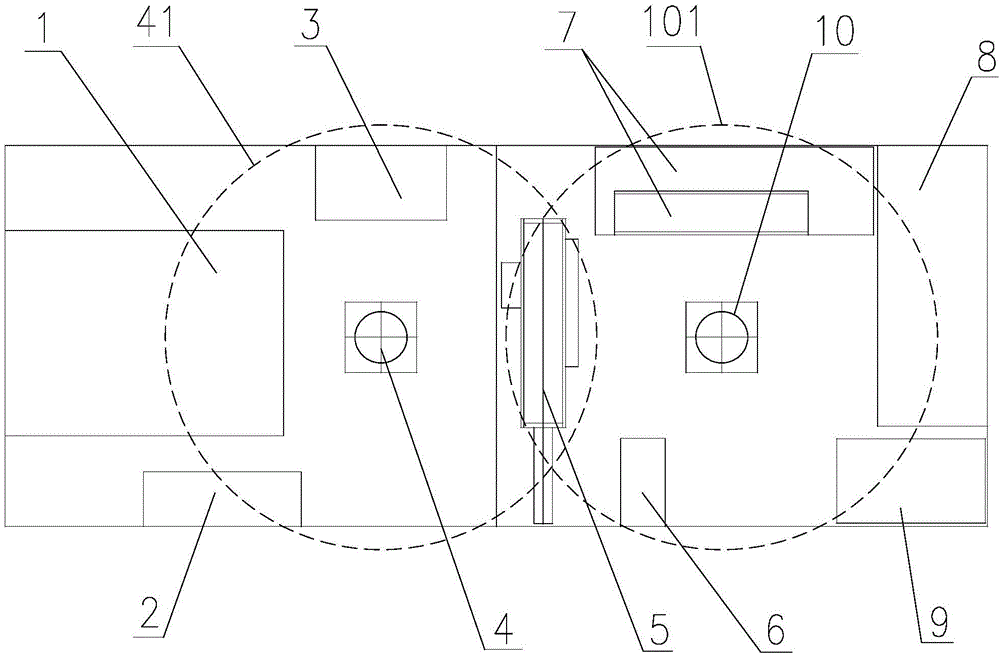

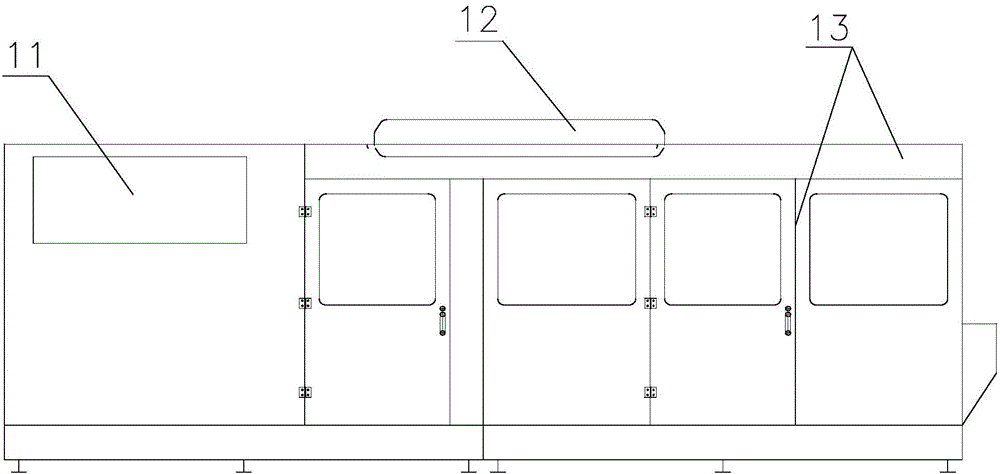

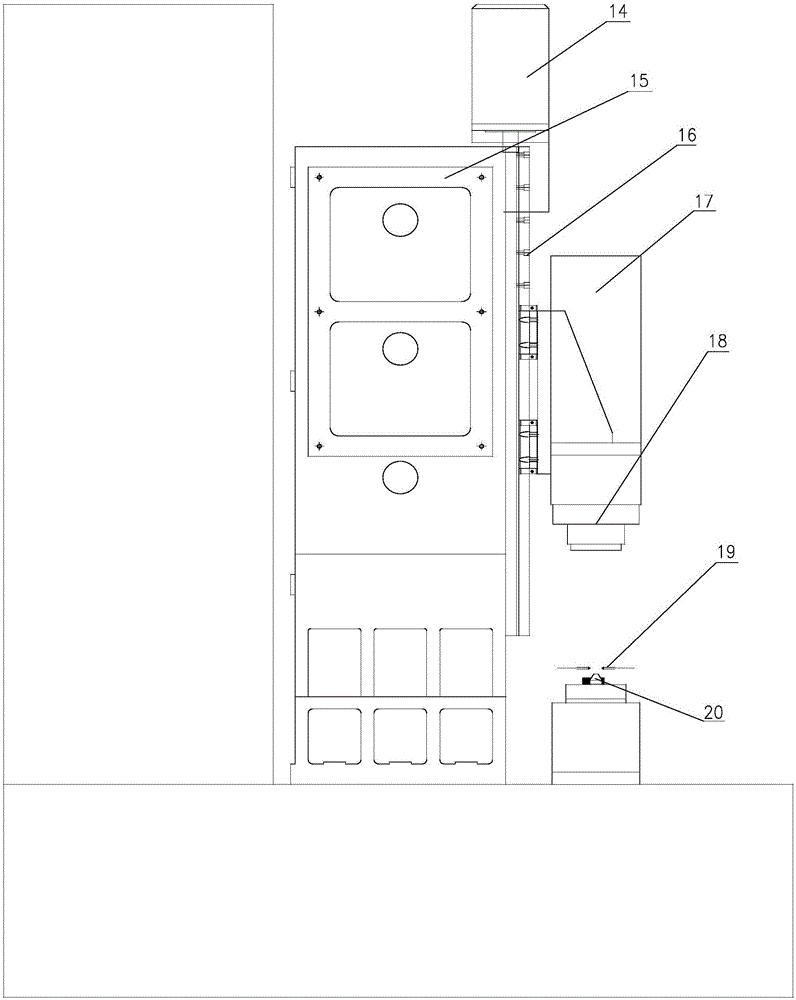

[0048] like Figure 1 to Figure 5 As shown, a combined camshaft automatic assembly system includes a first robot 4 and a second robot 10, and the area around the first robot 4 is equipped with an assembly machine 1, a steel pipe silo 2, an assembly parts silo 3, and a steel pipe silo 2 is used to hold the steel pipe 541 required for the assembly of the combined camshaft, the assembly parts bin 3 is used to hold the cam 542 required for the assembly of the combined camshaft, and the assembly machine 1 is used to install several cams on the outside of the steel pipe to assemble the combined cam Shaft initial product; the area around the second robot 10 is equipped with a stretching machine 5, a laser code scanning device 6, an end assembly assembly device 7, a torque detection device 8, and a finished product storage and transportation device 9, and the stretching machine 5 is used In the steel pipe 541 of the original product of the combined camshaft, the steel ball 541 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com