Novel numerically-controlled machine tool counterweight system

A CNC machine tool, a new type of technology, applied in the direction of maintenance and safety accessories, metal processing machinery parts, metal processing equipment, etc., can solve the problems of acceleration of gravity and temperature rise, affecting the accuracy of the spindle, affecting the stability of the machine tool, processing accuracy and life. , to achieve the effect of ensuring stability, compact structure, and reducing the requirements of the installation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

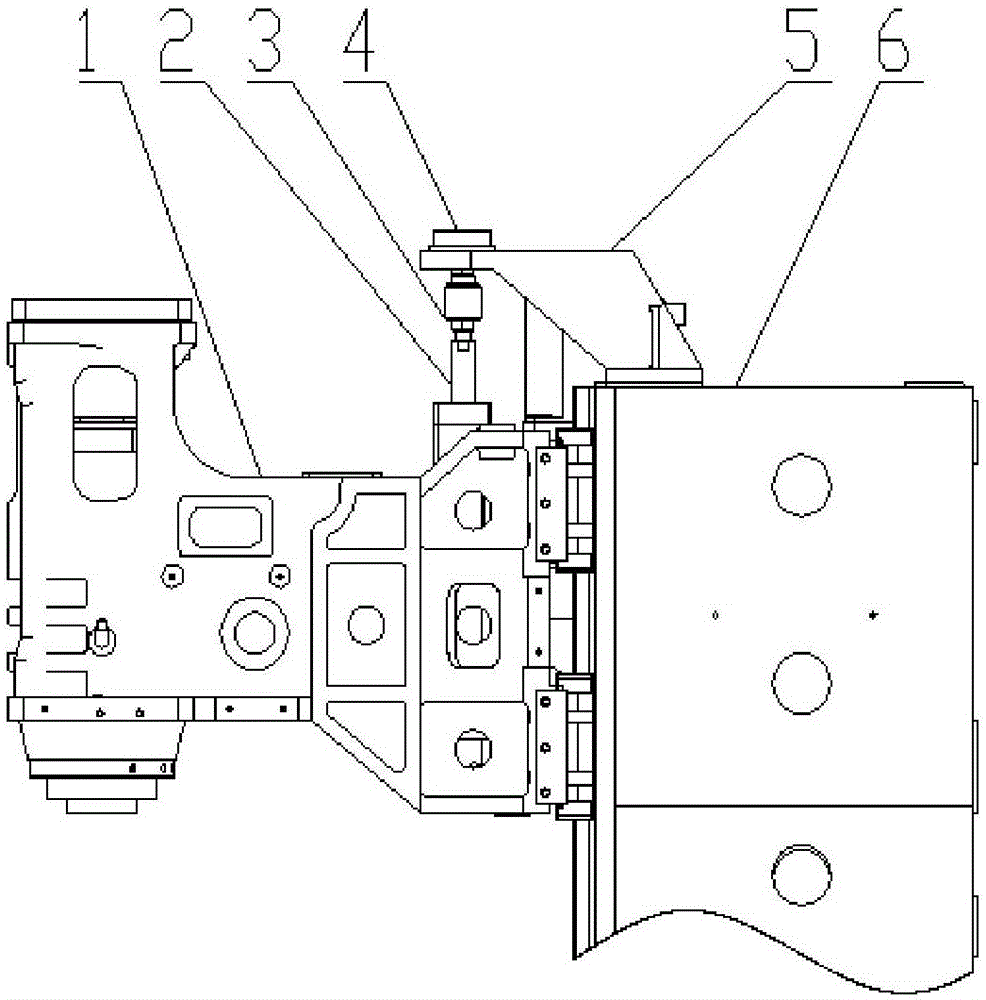

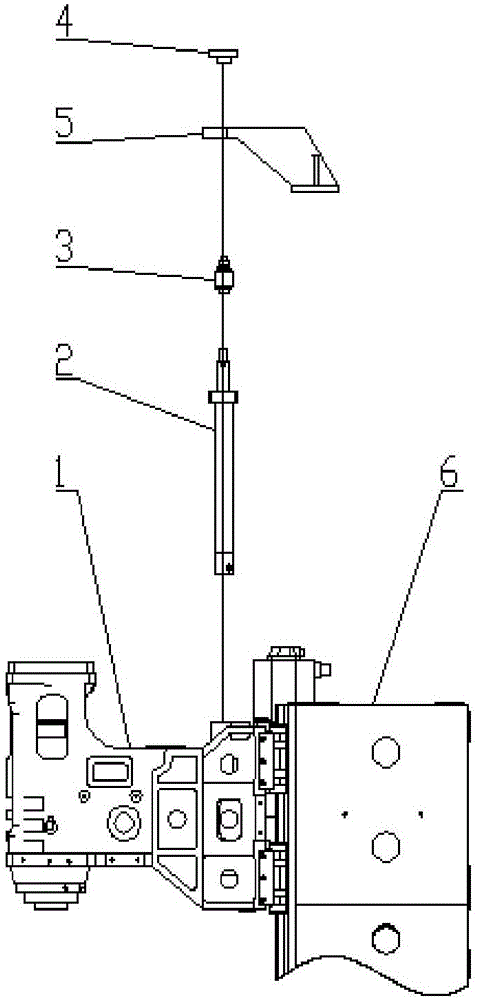

[0016] This novel CNC machine tool counterweight system of the present invention, as figure 1 , 2 As shown, including the oil cylinder 2, there is a space for the oil cylinder 2 on the headstock 1, the cylinder body of the oil cylinder 2 is placed in the headstock 1, and can be completely embedded in the oil cylinder 2, and the oil cylinder counterweight seat 5 is connected to the side of the column 6 , The oil cylinder counterweight seat 5 is connected with the telescopic rod end of the oil cylinder 2. This kind of counterweight system can balance the gravitational acceleration generated by the spindle during movement, reduce vibration, ensure the stability of the machine tool, and prolong the service life of the machine tool.

[0017] In the present invention, preferably, a floating joint 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com