High-speed-motor-train-unit pantograph deicing carbon sliding plate

A technology for high-speed EMUs and pantographs, applied to motor vehicles, electric vehicles, collectors, etc., can solve problems affecting the operation of EMU trains, affecting the normal operation of EMUs, insulation contact, etc., to ensure safe and normal operation, Prevent unsafe accidents and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

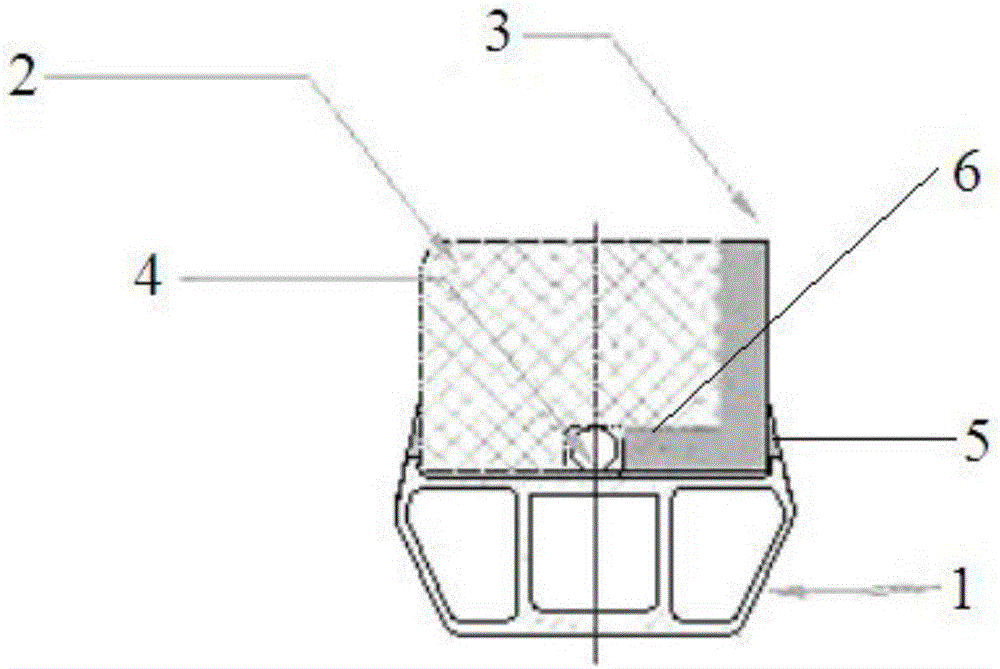

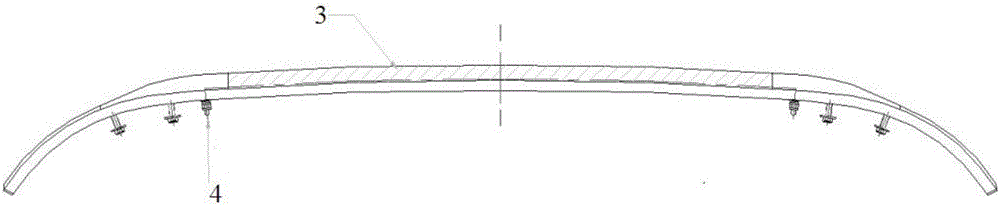

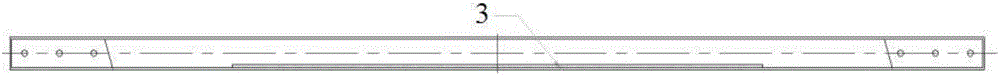

[0023] Such as Figure 1 to Figure 4 As shown, a high-speed EMU pantograph deicing carbon slide plate includes an aluminum bracket 1, a carbon bar 2 and an L-shaped copper plate 3, and the carbon bar 2 and the L-shaped copper plate 3 are fixed on the aluminum bracket 1 On the surface, the L-shaped copper plate 3 is arranged on the front end of the carbon strip 2, and a groove 6 is cut at the bottom of one side of the carbon strip 2, and the short side of the L-shaped copper plate 3 is located in the groove 6 so that one side of the carbon strip 2 presses the L L-shaped copper plate 3, the top of the long side of the L-shaped copper plate 3 is at the same height as the carbon strip 2, and an ADD air channel 4 is also provided inside the carbon strip 2.

[0024] The pantograph deicing carbon slides in this embodiment are double deicing carbon slides, and the installation diagram is as follows Figure 4 shown. The two sides of the upper surface of the aluminum bracket 1 of the ...

Embodiment 2

[0029] Such as Figure 5 to Figure 7 As shown, on the basis of Embodiment 1, the other side of the carbon strip 2 is also provided with an L-shaped copper plate 3, that is, the second L-shaped copper plate 8; the bottom of the other side of the carbon strip 2 is cut with a second groove , the short side of the second L-shaped copper plate 8 is located in the second groove so that the other side of the carbon strip 2 presses the L-shaped copper plate, and the long side top of the second L-shaped copper plate 8 is in contact with the carbon strip 2 at the same height. Such a pantograph deicing carbon slide forms a single deicing carbon slide.

[0030] In the second embodiment, if the width of the aluminum bracket 1 and the carbon strip 2 is increased, it is only necessary to set the L-shaped copper plate 3 on one side of the carbon strip 2, and there is no need to set it on the other side of the carbon strip 2. L-shaped copper plate 3 also can realize the deicing carbon slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com