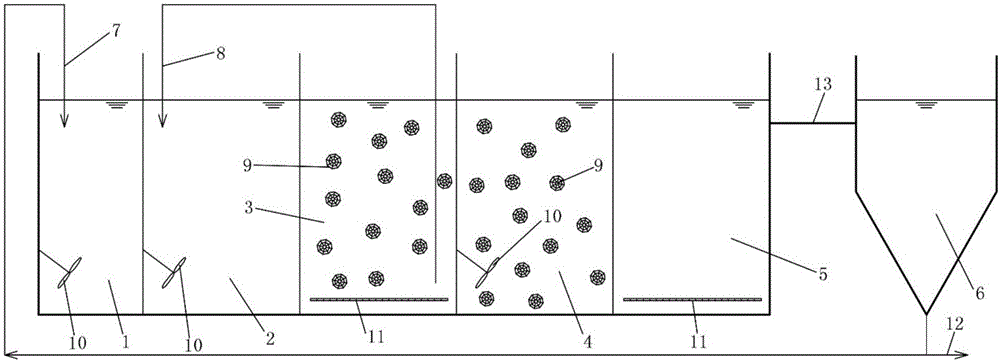

Bardenpho nitrogen and phosphorus removal technology based on MBBR

A denitrification and phosphorus removal, process technology, applied in aerobic and anaerobic process treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Large floor area and other problems, to achieve the effect of reducing TP, increasing biomass, and saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The effluent from the grit chamber of a city sewage plant is used as the influent water, the water temperature is 10-25°C, the BOD concentration in the water is 80-120mg / L, NH 4 + -N concentration is 35~45mg / L, TN concentration is 45~55mg / L, TP concentration is 5~8mg / L, and the effective volume of the reactor is 7.5m 3 , anaerobic pool 0.5m 3 , the first anoxic pool 3m 3 , the first aerobic pool 3.2m 3 , the second anoxic pool is 0.6m 3 , the second aerobic pool is 0.2m 3 . The effective specific surface area of the suspended filler used is 620m 2 / m 3 . The specific gravity before filming is 97kg / m 3 . Inlet flow is 0.35m 3 / h. Due to the lack of carbon sources in the influent, carbon sources were added to the first anoxic zone and the second anoxic zone respectively, and the dosage was 100-120mg / L.

[0032] When starting up, the activated sludge in the biological pool of the sewage plant is used as the inoculation sludge, and the film-hanging suspended f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com