Movable sludge treatment system

A sludge treatment, mobile technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc. To meet the delivery requirements, unable to meet the harsh conditions and other problems, to achieve the effect of remarkable treatment effect, good mud output effect, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the examples, but the present invention is not limited to the following examples.

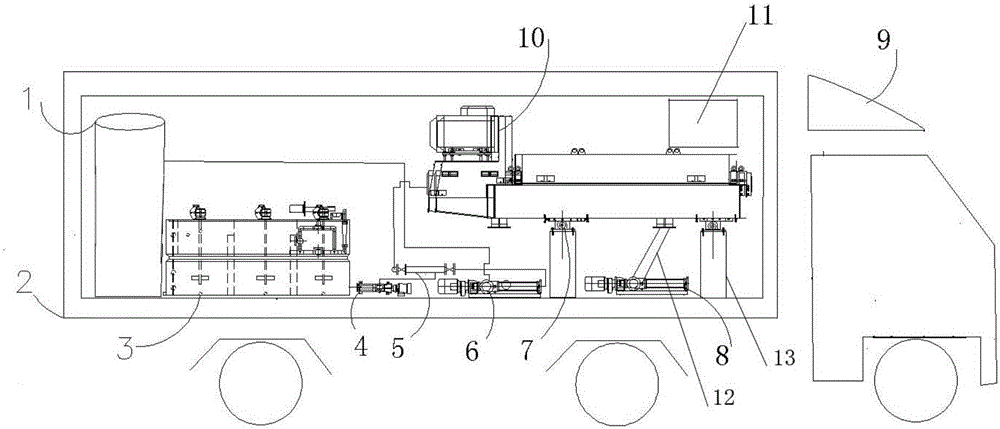

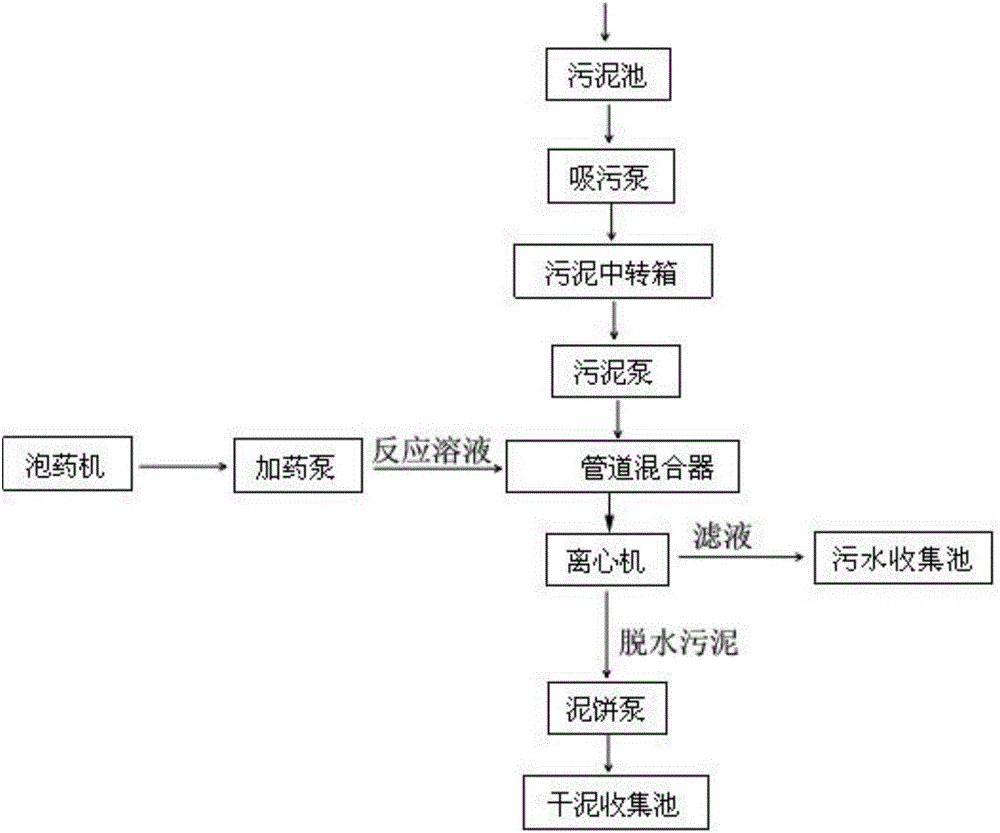

[0032] Such as figure 1 As shown, the present invention provides a movable sludge treatment system, comprising: a motor vehicle body 9, a sewage suction device, a control device 11, a mixing device, a dosing device, a centrifugal machine 10, mud cake pump 8; the dosing device communicates with the drug inlet of the mixing device, and is used for quantitative dosing in the mixing device, and the mixing device is used for fully mixing the sludge and sewage reaction agent solution , its inlet is communicated with the sewage suction device, and the outlet is communicated with the mud inlet of the centrifuge 10, and the dehydrated sludge and filtrate of the centrifuge 10 pass through the sewage pipe 12 and the drain pipe (not shown in the figure) respectively. ) is discharged for the next step of processing; the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com