A new type of continuous porous foam ceramic and its preparation method

A foamed ceramic and porous technology, which is applied in the field of continuous porous foamed new ceramics and its preparation, can solve the problems of complex manufacturing process, heavy load, no air permeability, etc., and achieve short service life, great contribution, and easy corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

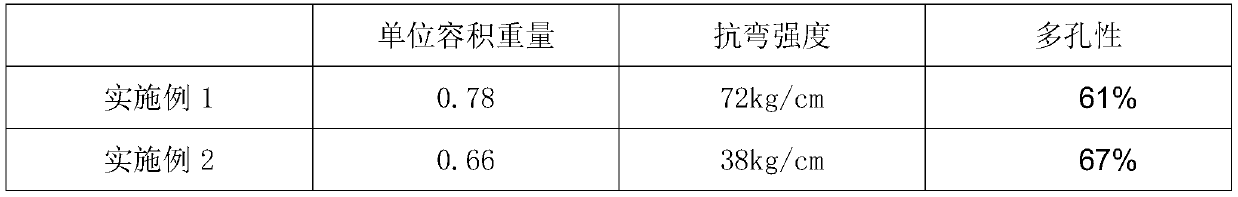

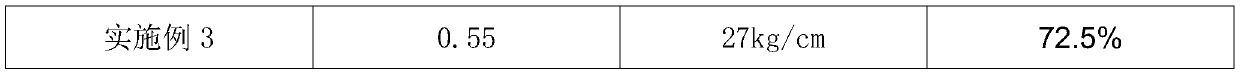

Embodiment 1

[0016] A new type of continuous porous foamed ceramics, prepared from the following raw materials in the following proportions by weight: 60 parts of waste slag, 40 parts of clay, the particle size of the waste slag is 1mm.

[0017] The preparation method is to mix 60 parts by weight of waste slag, 40 parts of clay, and 20 parts of water into a solid state, knead it into a predetermined shape with a vacuum kneader, and dry it until the water content is below 1%. When the temperature reaches 700°C, the temperature is gradually raised in units of 20°C, and when the temperature reaches 850°C, the temperature is gradually raised in units of 10°C to make each particle explode explosively, and then use 1150°C Sintered into ceramic porous body.

Embodiment 2

[0019] A new type of continuous porous foamed ceramics, prepared from the following raw materials in proportion by weight: 70 parts of waste slag, 20 parts of clay, and 10 parts of bentonite. The particle size of the waste slag is 0.8mm.

[0020] The preparation method is to mix 70 parts by weight of waste slag, 20 parts of clay, 10 parts of bentonite and 25 parts of water into a solid state, knead it into a predetermined shape with a vacuum kneader, dry it until the water content is below 1%, and place it in the Sintering in the temperature range of 700°C-1000°C, when the temperature reaches 700°C, the temperature is gradually increased by 30°C as a unit, and when the temperature reaches 850°C, the temperature is gradually increased by 10°C as a unit, so that each particle is explosively bubbling, Later, it is sintered at 1000°C to form a ceramic porous body.

Embodiment 3

[0022] A new type of continuous porous foamed ceramics, prepared from the following raw materials in proportion by weight: 74 parts of waste slag, 18 parts of clay, and 8 parts of bentonite. The particle size of the waste slag is 1mm.

[0023] The preparation method is to mix 74 parts by weight of waste slag, 18 parts of clay, 8 parts of bentonite and 18 parts of water into a solid state, knead it into a predetermined shape with a vacuum kneader, dry it until the water content is below 1%, and place it in the Sintering in the temperature range of 700°C-1000°C, when the temperature reaches 700°C, the temperature is gradually raised in units of 35°C, and when the temperature reaches 850°C, the temperature is gradually increased in units of 10°C, so that each particle explodes. Later, it is sintered at 1100°C to form a ceramic porous body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com