Preparation technique of fosphenytoin sodium

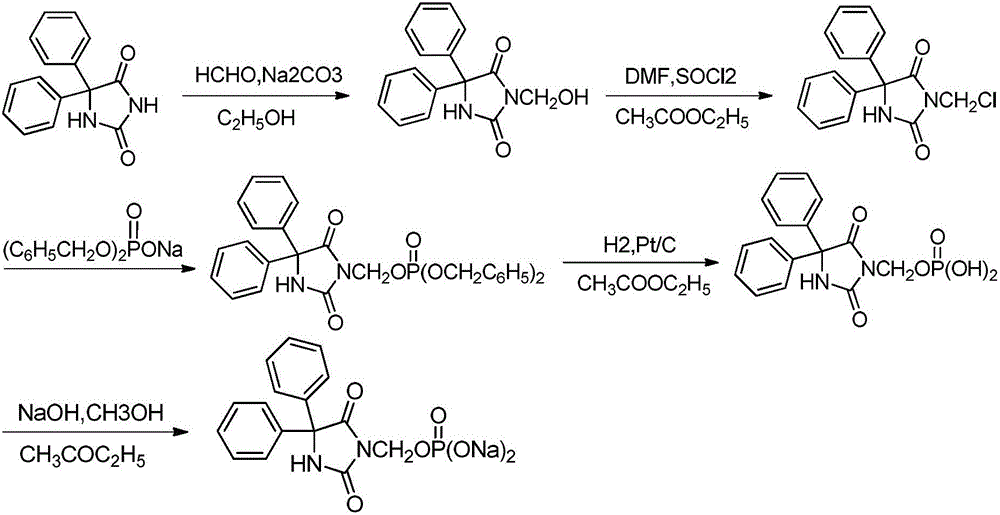

A technology for fosphenytoin sodium and preparation process, applied in the field of pharmaceutical synthesis, can solve the problems of difficult control of alkyl methanesulfonate, poor process controllability, heavy metal palladium residue, etc., and achieves shortened production cycle, high product purity, and related substance content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Add 10 g of phenytoin to 50 g of an aqueous solution of 37% by weight formaldehyde, react at 20-30°C for about 25 hours, filter, and dry the filter cake at 80-90°C under normal pressure until the water content is below 0.5%, to obtain 3-hydroxymethyl Base-phenytoin 10.2g, molar yield about 91%.

[0051] (2) Add 16g of 1,2,4-triazole into 130g of dichloromethane and stir, then add 29g of triethylamine, lower the temperature to 0-10°C, add 11g of phosphorus oxychloride dropwise, and keep the reaction for 1h after the dropwise addition, 10.0 g of 3-hydroxymethyl-phenytoin was added under temperature control at 0-10° C., and after the addition was completed, the reaction was kept for 1 h. Then add sodium bicarbonate 10g / water 100g solution under temperature control to adjust the pH value of the system to 7.5-8.0, stir the reaction for 1h, separate the liquid, take the water phase and add 100g ethanol to crystallize, then cool down to 0-10°C and keep stirring for 1h, fil...

Embodiment 2

[0054] (1) Add 10 g of phenytoin into a mixture of 50 g of 37% by weight formaldehyde solution and 10 g of ethanol, react at 20-30° C. for about 25 hours, filter, and dry the filter cake at 80-90° C. under normal pressure until the water content is below 0.5%. , to obtain 10.1 g of 3-hydroxymethyl-phenytoin with a molar yield of about 90.1%.

[0055] (2) Add 16g of 1,2,4-triazole into 130g of dichloromethane, add 29g of triethylamine to dissolve, lower to -5-5°C, add 11g of phosphorus oxychloride dropwise, and keep warm for 2h after the dropwise addition , add 10.0g of 3-hydroxymethyl-phenytoin at temperature control -5-10°C, keep warm for 1h, then add sodium carbonate 6g / water 100g solution at temperature control to adjust the pH value of the system to 7.5-8.0, stir for 1h, divide Add 100 g of acetone to the water phase to crystallize, cool to 0-10° C. and keep stirring for 1 h, and filter to obtain 13.4 g of fosphenytoin sodium crude product, with an HPLC purity of 99.15% an...

Embodiment 3

[0058] (1) Add 10 g of phenytoin into 50 g of an aqueous solution of 37% by weight formaldehyde, react at 28° C. for 28-30 h, filter, and dry the filter cake at 80-90° C. under normal pressure until the water content is below 0.5%, to obtain 3-hydroxymethyl- 10.2 g of phenytoin, the molar yield is about 91%.

[0059] (2) Add 16g of 1,2,4-triazole into 130g of dichloromethane, add 29g of triethylamine to dissolve, lower to 0-10°C, add 11g of phosphorus oxychloride dropwise, and keep warm for 1h after the dropwise addition, Add 10.0g of 3-hydroxymethyl-phenytoin under temperature control at 0-10°C, after the addition is complete, keep warm for 1 hour, then add 7g of sodium carbonate dissolved in 100g of water under temperature control to adjust the pH of the system to 8.0-9.0, and stir for 1 hour , liquid separation, adding 100 g of ethanol to the water phase for crystallization, cooling to 0-10 ° C and stirring for 1 h, filtering to obtain 13.4 g of fosphenytoin sodium crude pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com