Special golden camellia tobacco flavor as well as preparation method and application thereof

A technology for tobacco flavor and characteristic golden flower, applied in the application, essential oil/spice, tobacco and other directions, can solve the problem of loss of low-boiling point flavor substances, reduce miscellaneous gas and irritation, improve taste, and improve smoking quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

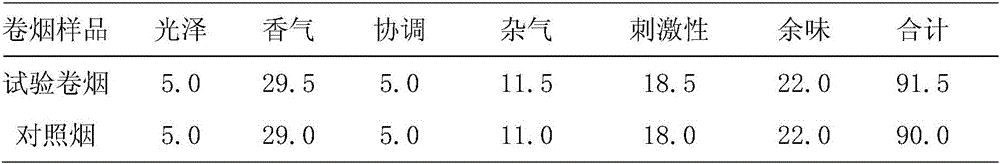

Examples

Embodiment 1

[0019] Take 200 grams of freeze-dried Camellia camellia flowers and put them into a clean container, add 10 kg of 50% ethanol aqueous solution, soak and stir for extraction at 35°C for 12 days, use qualitative filter paper to obtain the filtrate, soak and extract twice; Combine the ethanol extracts obtained by soaking and extracting twice, and then add them to the concentrator to concentrate under reduced pressure at a pressure of 0.02 MPa and a temperature of 40°C. Stop the concentration, and get a kind of characteristic golden camellia tea tobacco spice.

[0020] Take 100g of characteristic golden camellia flavoring for tobacco, dissolve it in 1000g of 95% ethanol, spray evenly on 110kg of shredded cigarette tobacco according to the flavoring process, and roll it into cigarettes.

Embodiment 2

[0022] Take 1 kg of freeze-dried Camellia camellia flowers and put them into a clean container, add 5 kg of 95% ethanol aqueous solution, soak and stir for extraction at 15°C for 1 day, filter with qualitative filter paper to obtain the filtrate, soak and extract twice; Combine the ethanol extracts obtained by soaking and extracting twice, and then add them to the concentrator to concentrate under reduced pressure at a pressure of 0.09 MPa and a temperature of 25°C. Stop the concentration, and get a kind of characteristic golden camellia tea tobacco spice.

[0023] Take 5g of characteristic golden camellia flavoring for tobacco, dissolve it in 500g of 50% ethanol, spray evenly on 505kg of shredded cigarette tobacco according to the flavoring process, and roll it into cigarettes.

Embodiment 3

[0025] Take 500 grams of freeze-dried Camellia camellia flowers and put them into a clean container, add 15 kg of 85% ethanol aqueous solution, soak and stir for extraction at a temperature of 30° C. for 9 days, filter with qualitative filter paper to obtain the filtrate, soak and extract twice; Combine the ethanol extracts obtained by soaking and extracting twice, and then add them to the concentrator to concentrate under reduced pressure at a pressure of 0.08 MPa and a temperature of 25°C. Stop the concentration, and get a kind of characteristic golden camellia tea tobacco spice.

[0026] Take 70g of characteristic golden camellia tobacco fragrance, dissolve it in 1000g of 80% ethanol, spray evenly on 133.75kg of shredded cigarette tobacco according to the flavoring process, and roll it into cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com