Construction method of oval suspended dome structure

A chord-supported dome and construction method technology, which is applied to the construction of chord-supported dome structures and the construction field of elliptical chord-supported dome structures, can solve the problems of high supporting tire frame, difficult control of precision, and deflection of the upper reticulated shell, etc. Save construction costs, ensure assembly accuracy, and have the effect of flexible expansion and contraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

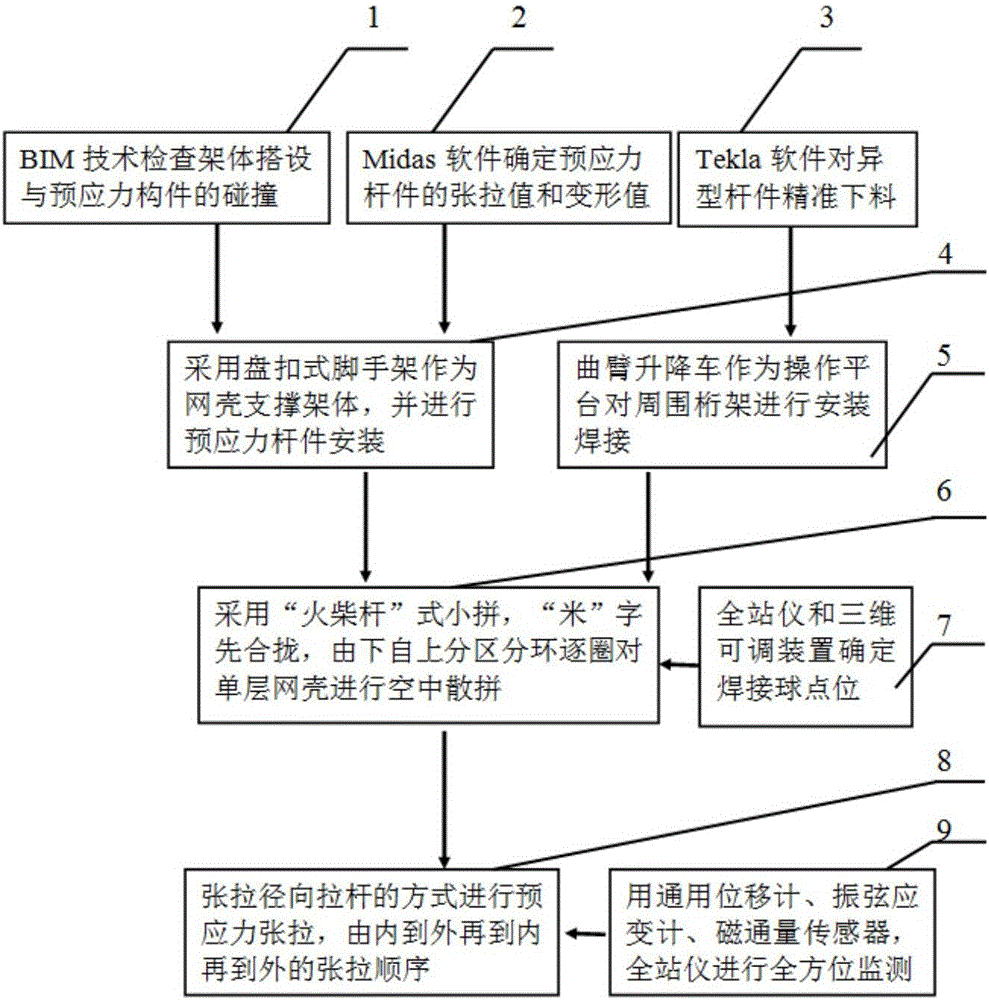

[0062] Such as figure 1 As shown, a construction method of an elliptical suspensive dome structure includes the following steps: 1) Using BIM technology to check the collision between the frame erection and the prestressed member 1, 2) Using Midas software to determine the tension value of the prestressed member and deformation value 2, 3) Use Tekla software to accurately cut the special-shaped rods 3, 4) Use the buckle-type scaffolding as the support frame of the reticulated shell, and install the prestressed rods 4, 5) Use the crank arm lift truck as the Install and weld the surrounding trusses on the operating platform 5, 6) Use the "match pole" type small assembly, the "meter" character is closed first, and the single-layer reticulated shell is scattered in the air from the bottom to the top and divided into rings 6, 7) Use a total station and a three-dimensional adjustable device to determine the position of the welding ball 7, 8) Use a radial tension rod for prestressed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com