A method for installing roof trusses of large-span and large-space steel structures

An installation method and a large-span technology, applied to roofs, building components, building structures, etc., can solve the problems of reducing component assembly workload, reducing component segmentation, and increasing construction costs, so as to reduce component assembly workload and reduce Segmentation of components and the effect of saving construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

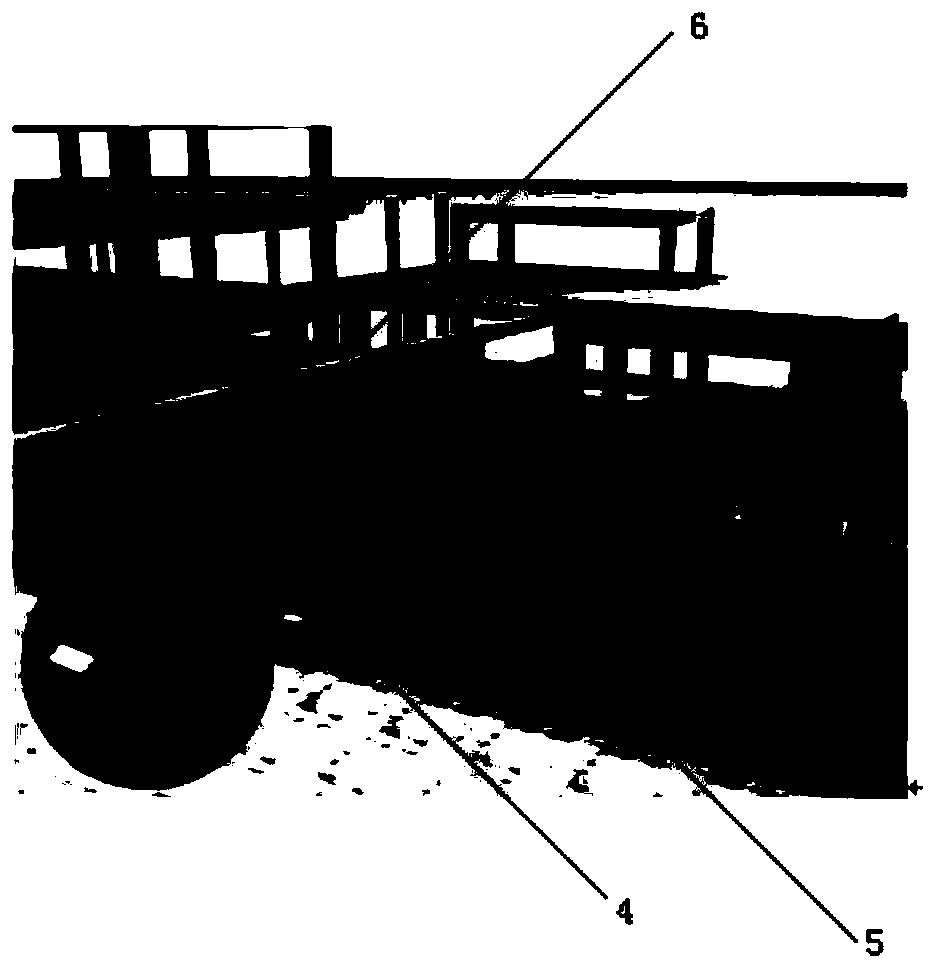

[0038] This embodiment is used for the installation of roof trusses of Chengxing Building. Chengxing Building is located at No. 208 Huashan Road, Jiangyin City. Its total construction area is about 149,725.25 square meters, the ground area is about 108,632.51 square meters, and the underground area is 41,092.74 square meters. The height of the super high-rise tower is 227.3 meters, the height of the highest point of the curtain wall is 238.8 meters, and the height of the podium structure is 23.40 meters. The steel structure mainly includes the roof long-span truss structure, steel stairs and steel columns; *29m, composed of 5 long-span trusses and steel beams, the span of a single truss is about 28.7m, and the weight is about 26T.

[0039] Chengxing Building roof truss installation, the specific steps are as follows:

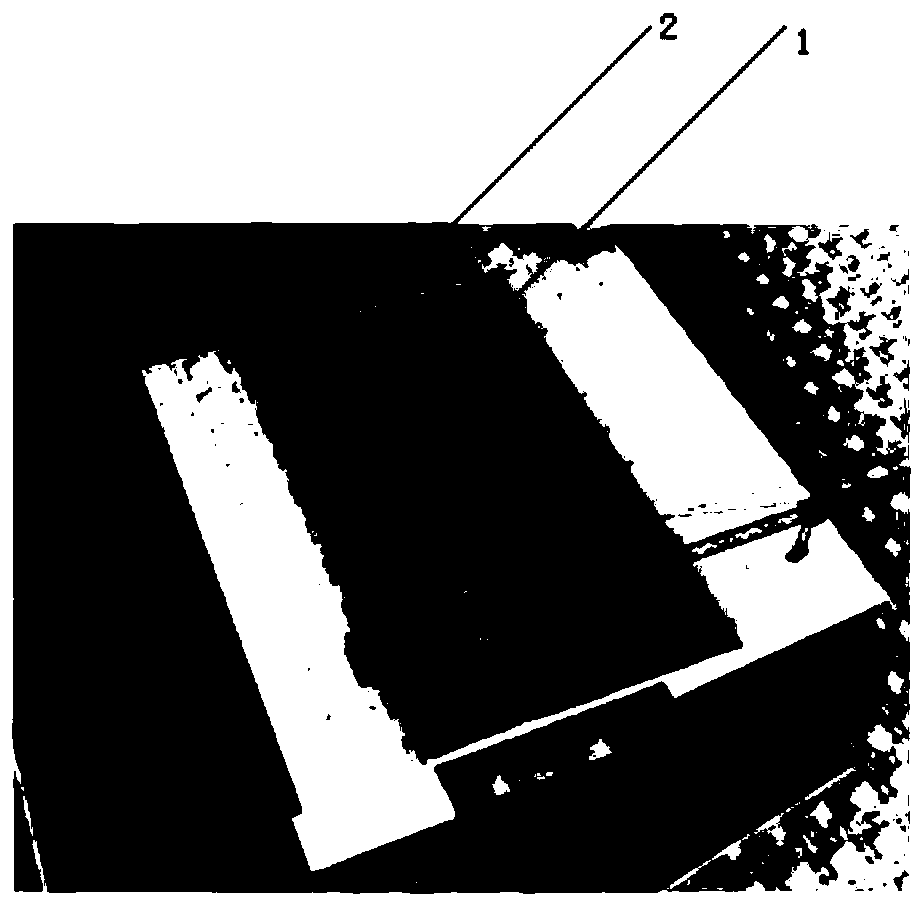

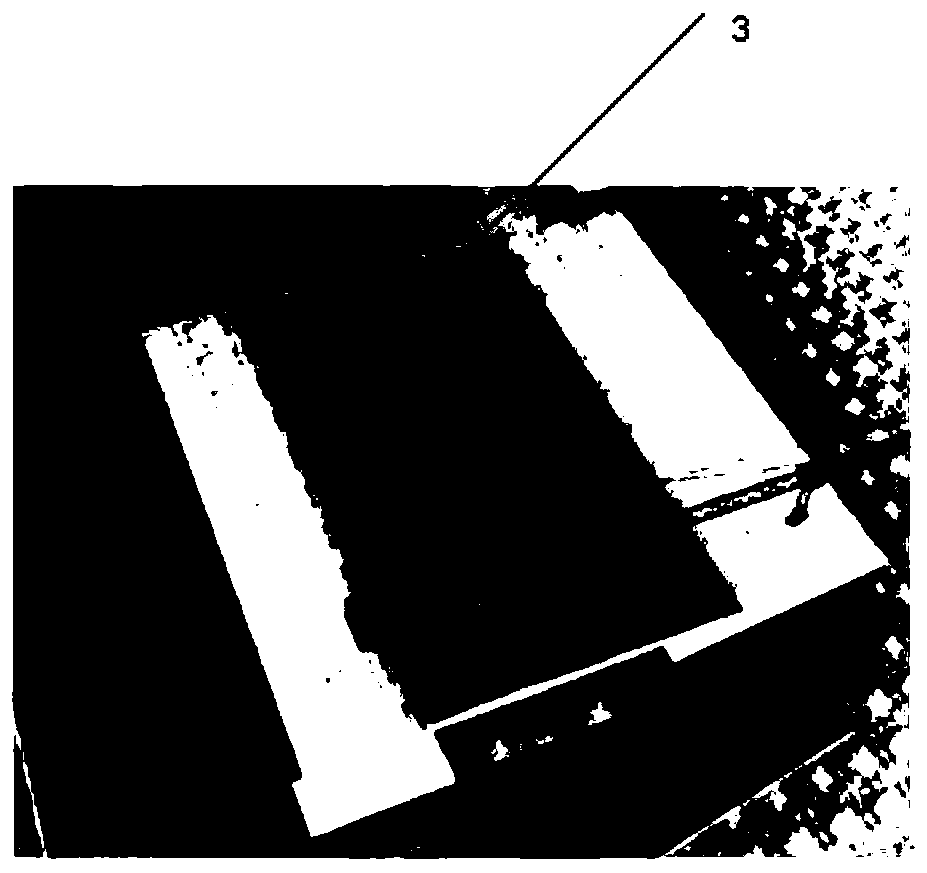

[0040] (1) laying slide rails

[0041] The sliding track is fixed on the reinforced concrete beams on both sides of the roof through embedded parts, and the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com