Construction method of gantry type building construction lifting device

A technology of building construction and construction method, which is applied in the directions of portable hoisting device, hoisting equipment braking device, processing of building materials, etc. The effect of building construction efficiency, simple device operation and close structural connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

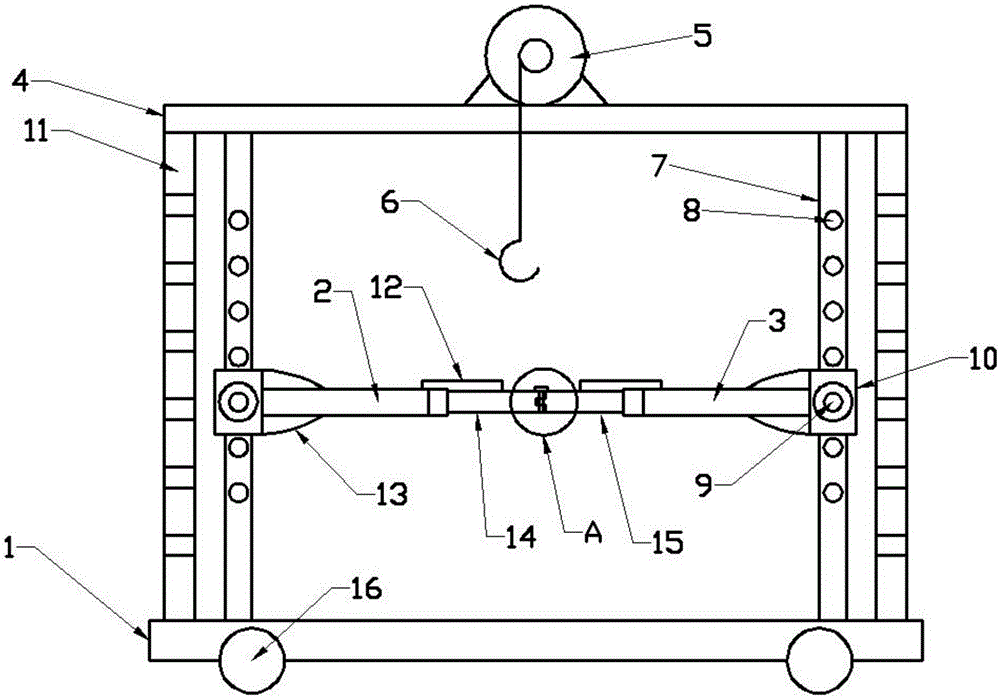

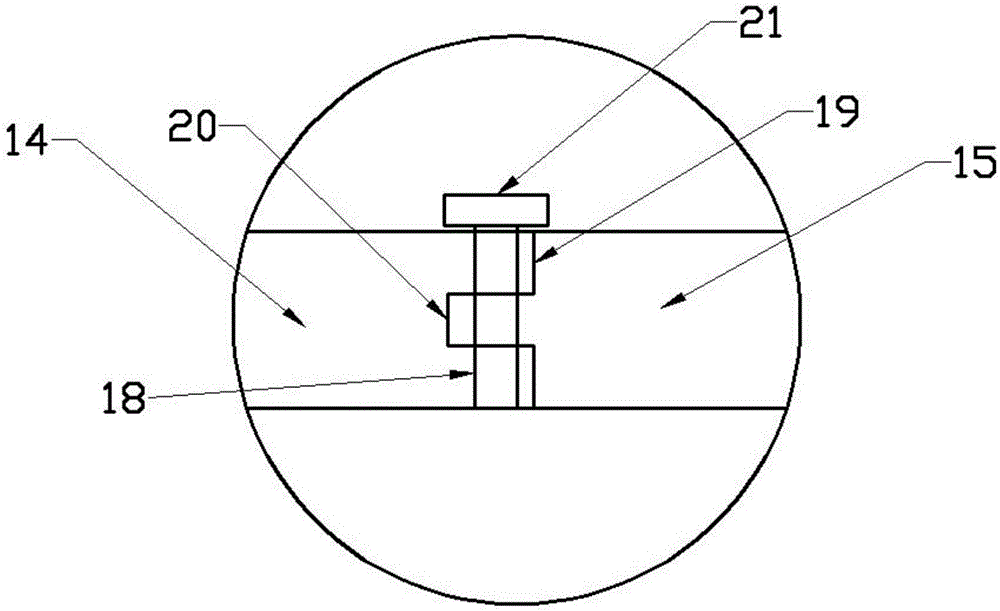

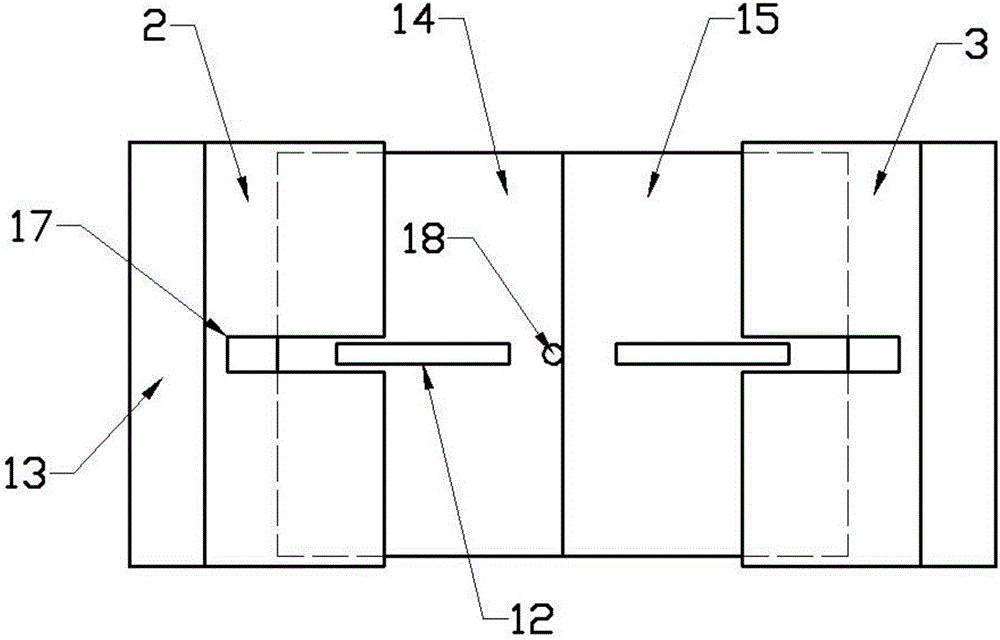

[0026] Embodiment 1: Please refer to the figure, in the embodiment of the present invention, the gantry type building construction lifting device includes a base plate 1, a beam 4, a hoist 5 and a column 7; the four corners of the base plate 1 are fixedly welded with the same column 7, and the column 7 is vertically provided with a row of adjustment holes 8, the distance between the adjustment holes 8 is 50 ~ 80mm, and the adjustment holes 8 on the four columns 7 are all corresponding to each other; the four columns 7 are equipped with adjustment sleeves 10 , the diameter of the inner circle of the adjustment sleeve 10 is equal to the diameter of the column 7, the adjustment sleeve 10 slides on the column 7, and a through hole corresponding to the adjustment hole 8 is provided on the side wall of the adjustment sleeve 10, between the through hole and the An adjusting bolt 9 passes through the adjusting hole 8 to ensure that the adjusting sleeve 10 is fixed on the column 7 so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com