Cvvt system

A valve timing and variable technology, applied in the direction of valve device, non-mechanical actuated valve, machine/engine, etc., to achieve the effect of improving fuel efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following description is exemplary only and is not intended to limit the invention or its application or uses. It should be understood that throughout the drawings, corresponding reference characters indicate like or corresponding parts and features.

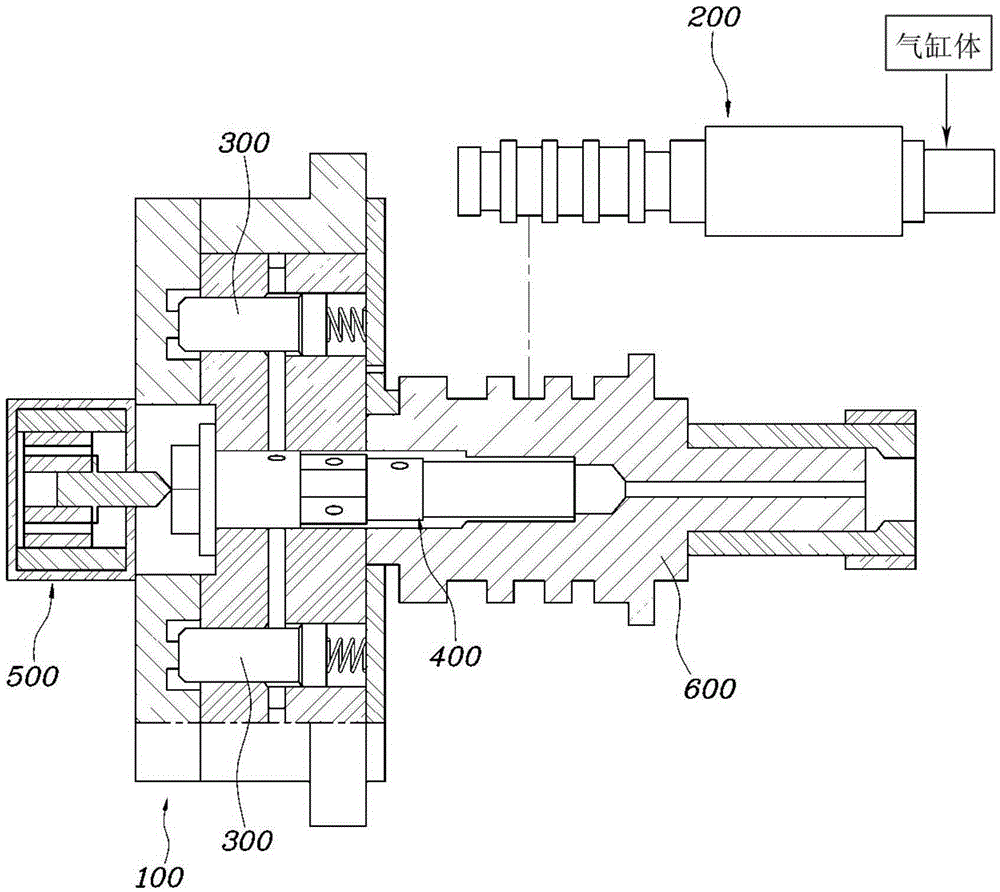

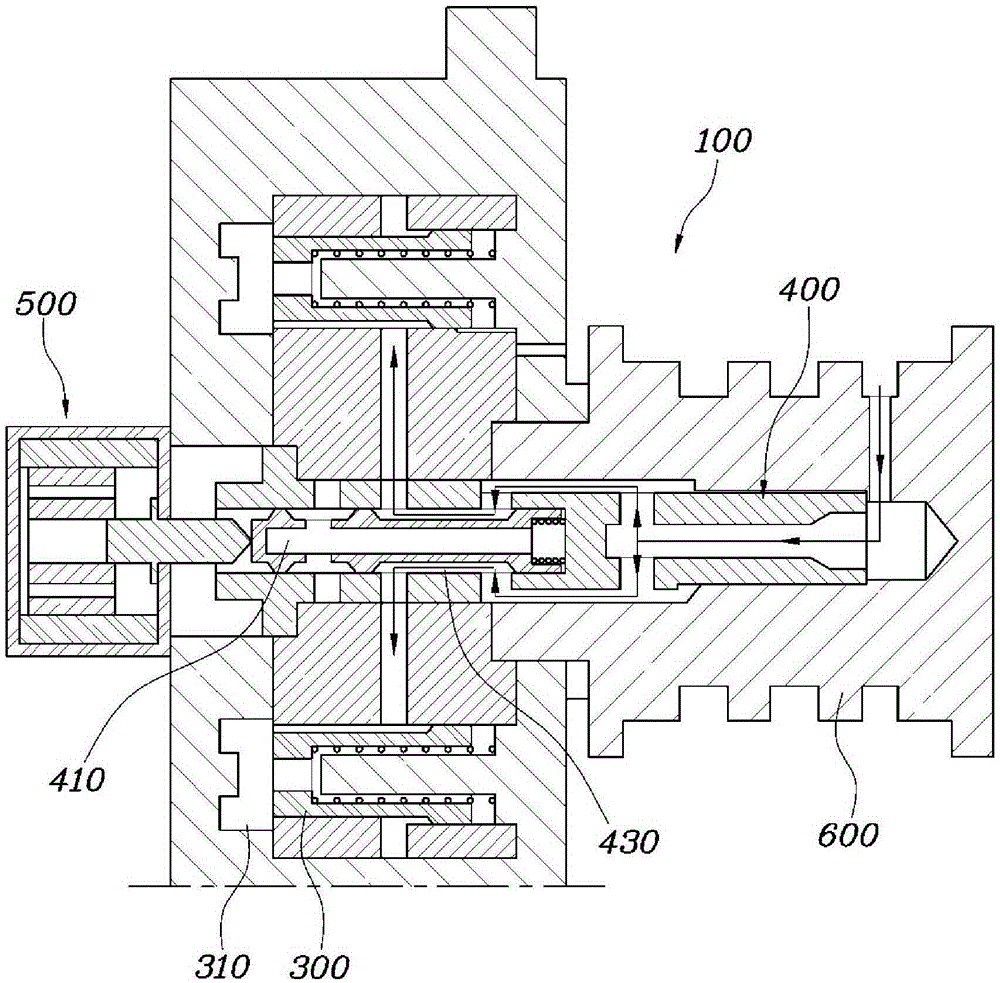

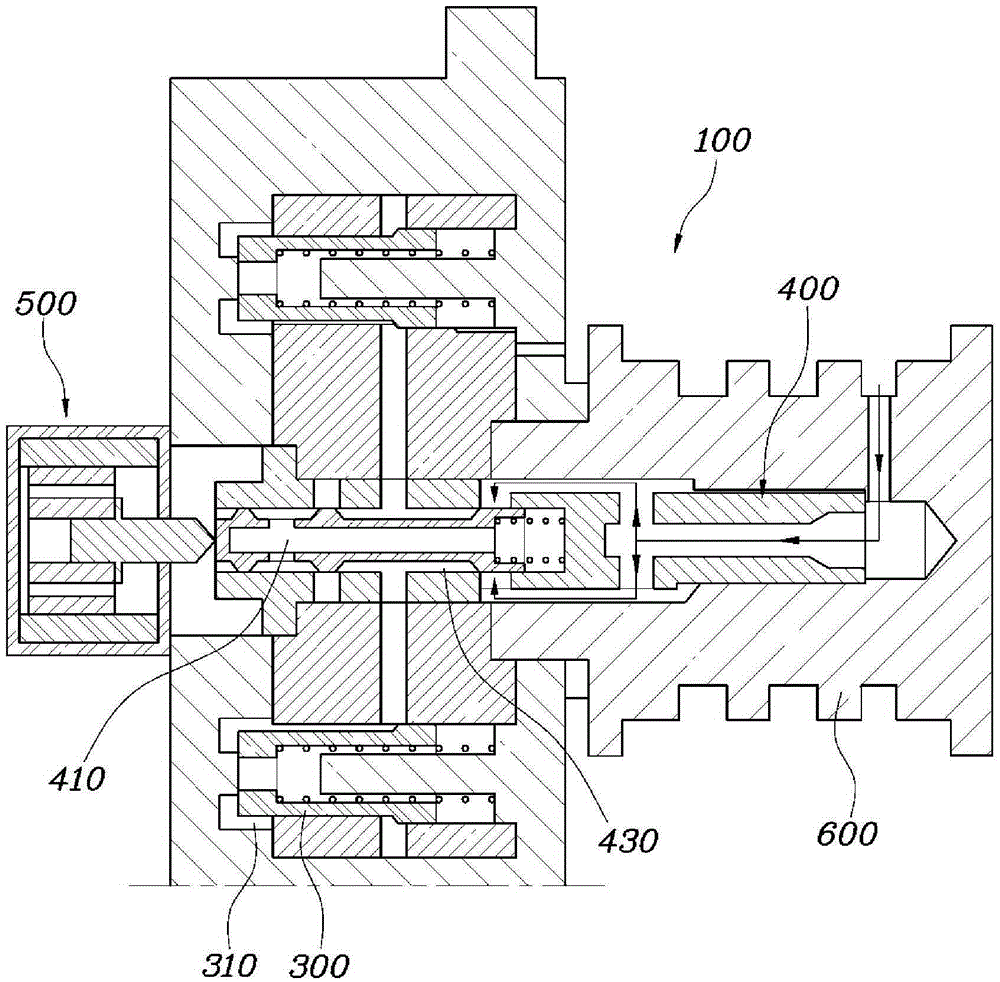

[0034] figure 1 To show a view of a CVVT system in accordance with one form of the present invention, figure 2 with image 3 is a view showing oil flow when the actuator 500 is operating / stopping. Figure 4 To show the view of the lock pin 300 and the lock pin hole 310, Figure 5 is a graph showing the locking speed of the lock pin 300 . Image 6 is a graph showing the advance / retard angles of the intake and exhaust valves. Figure 7 is a diagram showing the overall configuration of the system according to the present invention.

[0035] A continuously variable valve timing (CVVT) system according to an embodiment of the present invention includes: OCV 200 which supplies oil received from a cylinder block to CV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com