Tight connecting module and structure, mounting and dismounting method, crankshaft connecting rod mechanism and a rail structure

A technology for fastening connections and components, applied in the direction of connecting components, locking fasteners, threaded fasteners, etc., can solve the problem that the anti-rotation sleeve is difficult, cannot be taken out from the first anti-rotation hole, and has no use value, etc. problems, to achieve the effect of quick removal, convenient installation and cost reduction

Pending Publication Date: 2017-01-04

杨东佐

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the problems existing in the prior art, the technical problem to be solved by the present invention is to overcome the prior recognition by those skilled in the art that the anti-rotation sleeve is used to limit the rotation of the locking nut relative to the screw rod to realize the reverse loosening of the locking nut of the bolt. The anti-loosening technical solution, because the anti-rotation sleeve is difficult or impossible to take out from the first anti-rotation hole, resulting in inertial thinking of no use value, provides a method that uses the anti-rotation sleeve to limit the rotation of the lock nut relative to the screw to achieve screw locking The nut cannot rotate relative to each other, so that the lock nut of the screw rod will not be loosened due to the reverse rotation, and the anti-rotation sleeve can be taken out from the first anti-rotation hole quickly, conveniently and reliably, so that the detachment of the screw rod and the lock nut is fast, convenient and convenient. Reliable fastening and connection components and structures, installation and disassembly methods, crankshaft linkage mechanism, track structure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

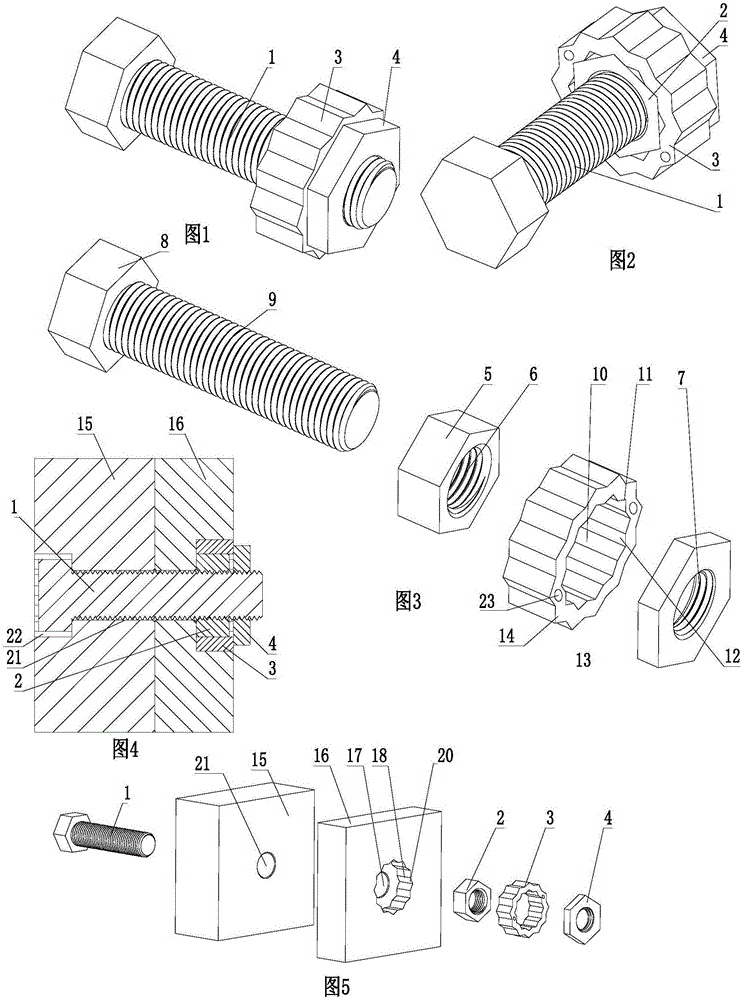

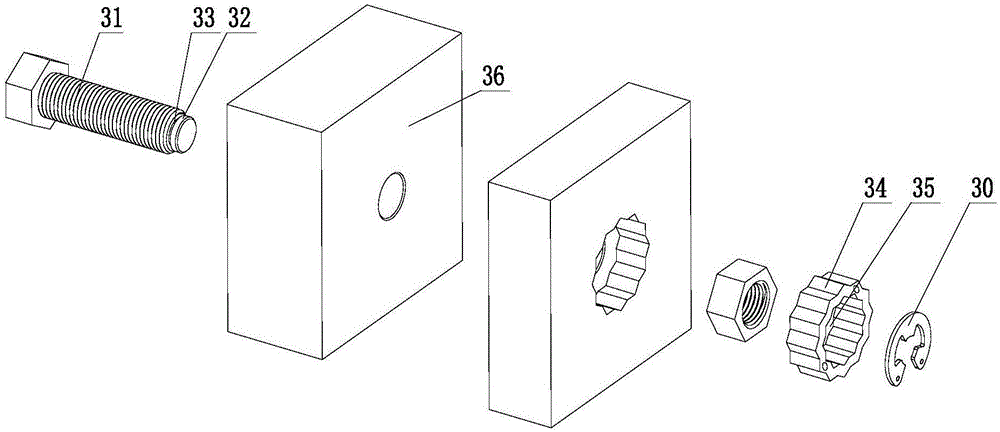

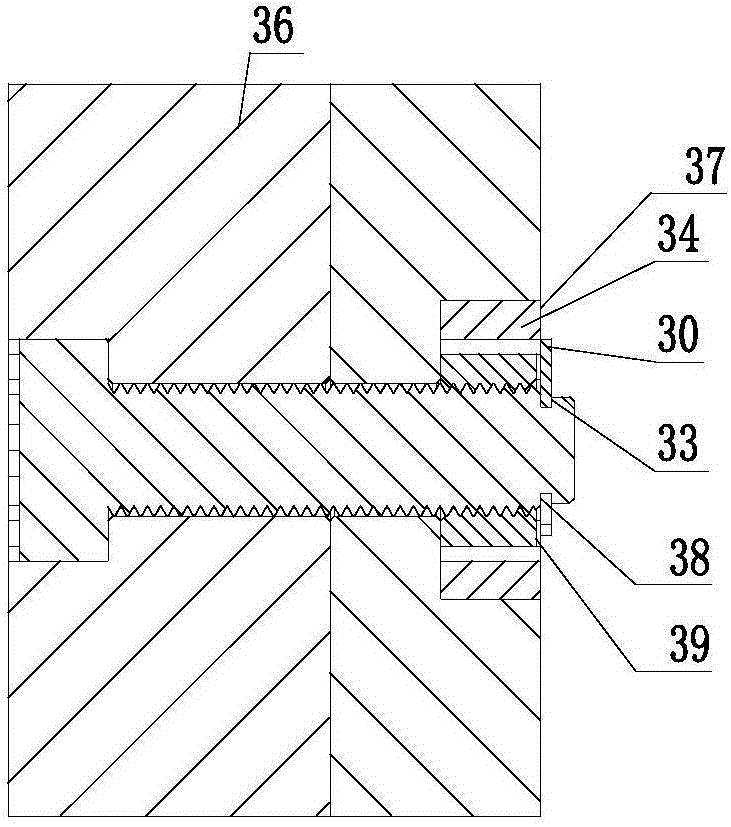

The invention discloses a tight connecting structure. The tight connecting structure comprises a main body, a secondary body and a tight connecting module; the tight connecting module includes a screw rod, a locking nut and a stop sleeve; a taking structure for taking out the stop sleeve is arranged on the hole wall of a first stop hole and / or the stop sleeve; the screw rod penetrates through the main body and the secondary body to be in threaded connection with the locking nut; the stop sleeve is mounted out of the locking nut and in the first stop hole, and is axially limited in the first stop hole; a first stop part at the outer periphery of the locking nut is matched with a second stop part on the wall of a stop through hole of the stop sleeve to restrain rotation of the locking nut corresponding to the stop sleeve; a third stop part at the outer periphery of the stop sleeve and a fourth stop part on the wall of a first stop hole are matched to restrain rotation of the stop sleeve corresponding to the secondary body; and the screw rod, the locking nut and the secondary body and the main body are mounted in a manner of not rotating, the tight connecting structure has the following advantages: the locking nut cannot reversely rotate to loosen corresponding to the screw rod; and the stop sleeve can be taken out from the first stop hole conveniently, quickly and reliably.

Description

A fastening connection component and structure, installation and disassembly method, crankshaft connecting rod mechanism, track structure Technical field: The invention relates to a fastening connection technology for statically connecting two or more objects with threaded pairs; in particular, it relates to a method for statically connecting crankshaft linkage mechanisms, track structures, aircraft, ships, equipment, aerospace equipment, etc. through threaded pairs. Fastening connection components, fastening connection structures and connections of mechanical parts on key parts of aircraft carriers, spaceships, rockets, engines, nuclear reaction equipment, trains, high-speed rail, rails, steel structure buildings, steel structure bridges, automobiles, etc. method, disassembly method, the use environment of these mechanical parts is particularly harsh, such as large vibration, high temperature environment, heavy load, etc., and the connection reliability of the threaded mechan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16B37/14F16B37/04F16B35/04F16B39/282F16B43/00F16B13/06F16B13/10F16C7/00E01B9/10E01B9/12E01B9/48E01B9/50

CPCE01B9/10E01B9/12E01B9/483E01B9/50F16B13/068F16B35/041F16B37/041F16B37/14F16B39/282F16B43/00F16C7/00E01B2201/04F16B13/10F16B35/04

Inventor 杨东佐

Owner 杨东佐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com