Power transmission using an inscribed cam and a cylindrical pinion

A power transmission device and pinion technology, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of easily increasing friction, reducing transmission capacity, reducing internal gears, etc., and achieving absorption Accuracy error, high transmission capacity, effect of eliminating backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, examples of the present invention will be described with reference to the drawings, but the present invention is not limited to these examples.

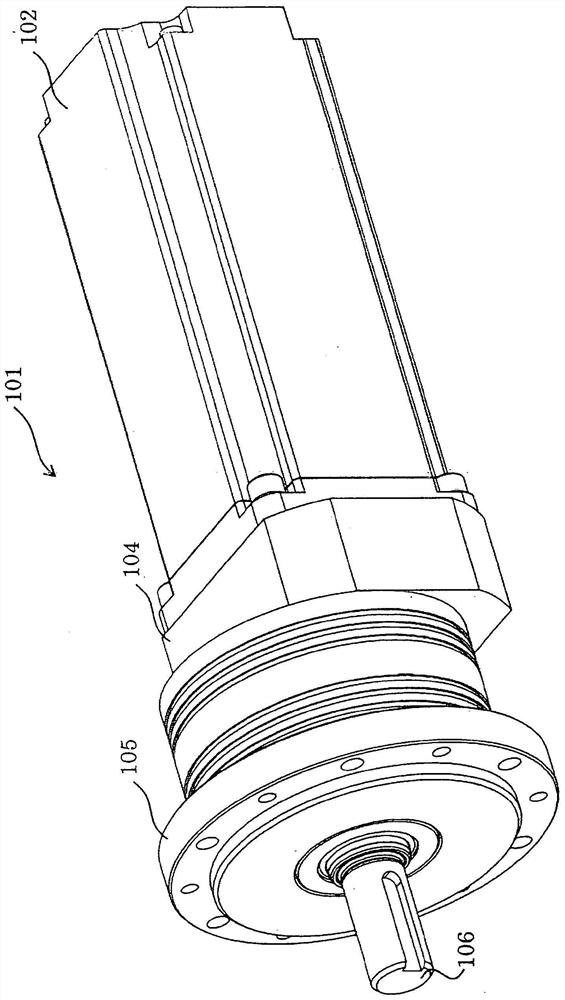

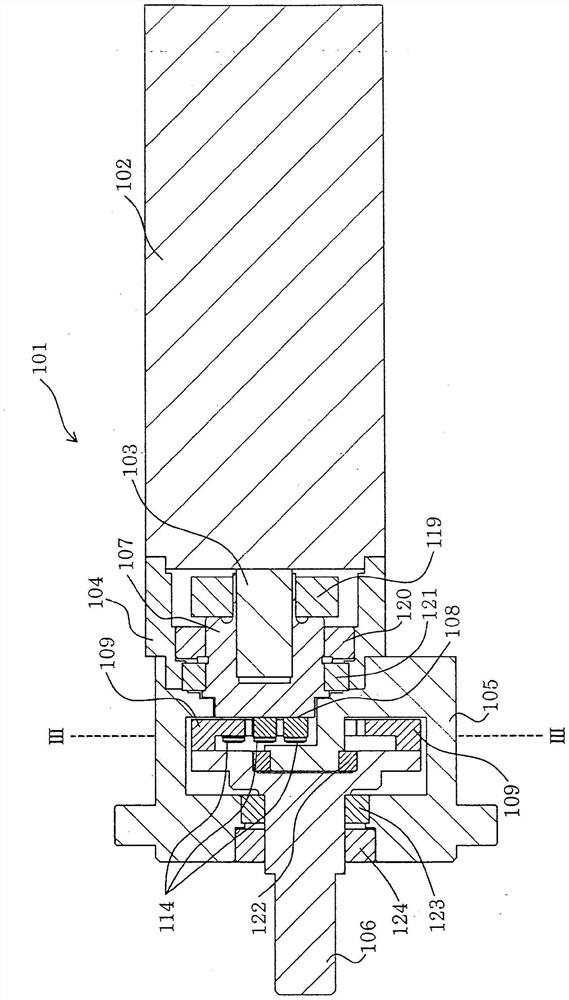

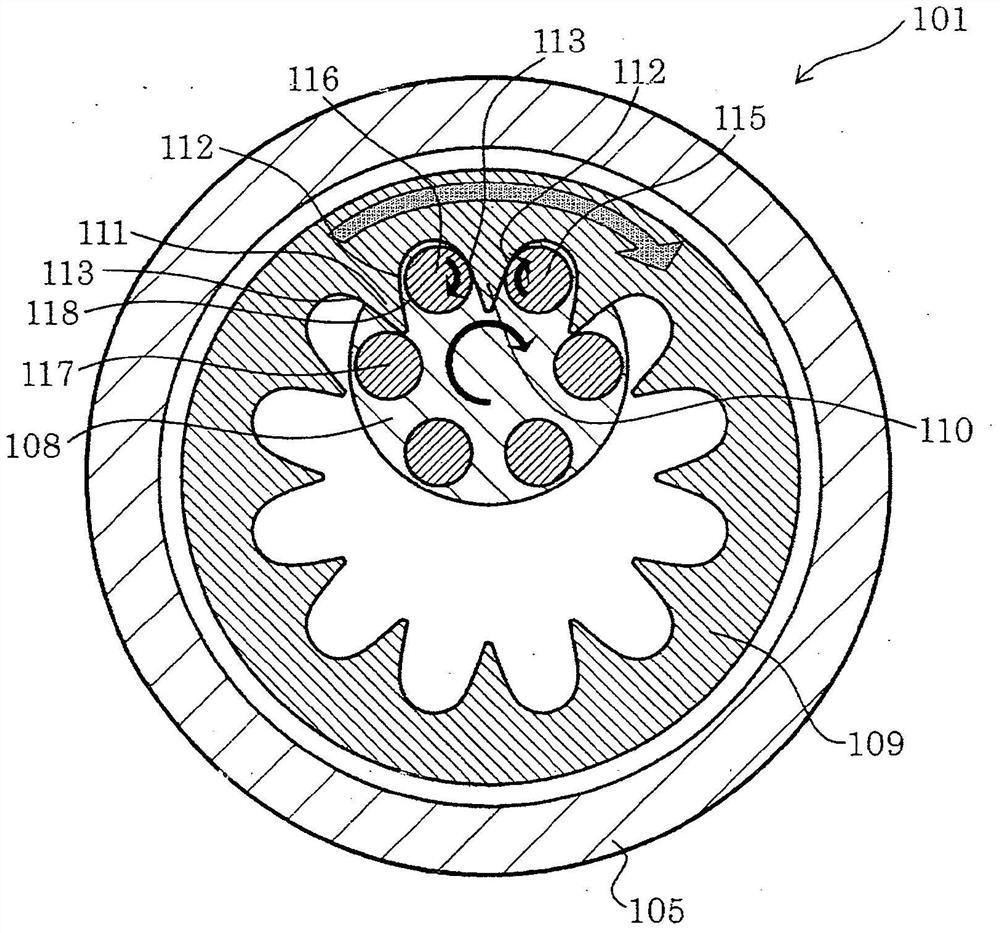

[0057] refer to Figure 1~4 , to describe an embodiment of the power transmission device of the present invention. figure 1 A schematic diagram of the power transmission device 101 is shown. The power transmission device 101 includes an electric motor 102 , housings 104 and 105 , and a rotatable output shaft 106 . figure 2 A cross-sectional view of the power transmission device 101 viewed from the side is shown. The power transmission device 101 includes: an electric motor 102 having a rotatable motor shaft 103; a substantially cylindrical turret 107 having a first end surface 108 and a second end surface, and is connected to the electric motor through a connecting element 119 on the second end surface side. The shaft 103 is connected and rotatable; a plurality of cylindrical pinions 114 are arranged on the turr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com