Thermocline heat storage device used for liquid heat storage

A technology of heat storage device and inclined temperature layer, which is applied to heat storage equipment, heat exchanger types, indirect heat exchangers, etc. The temperature of the fluid at the inlet of the thermal equipment is reduced, so as to achieve the effects of low manufacturing cost, improved heat storage effect, and continuous heat charging and discharging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

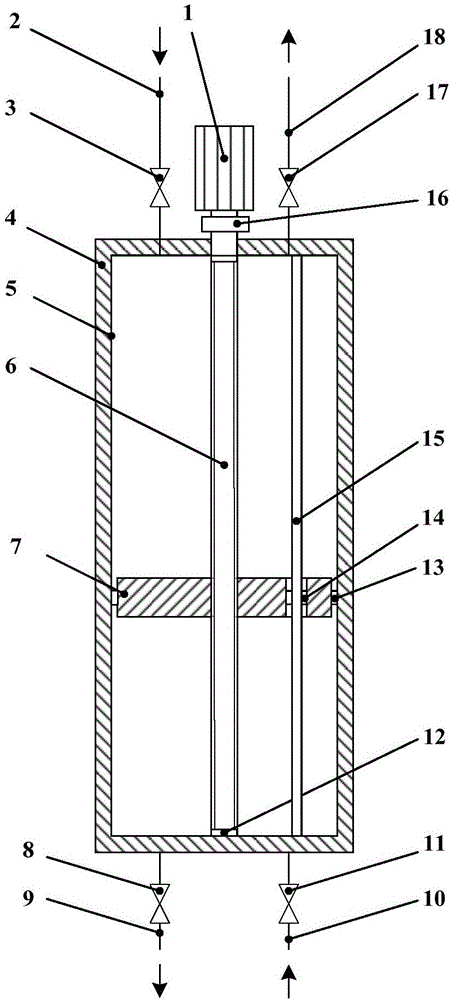

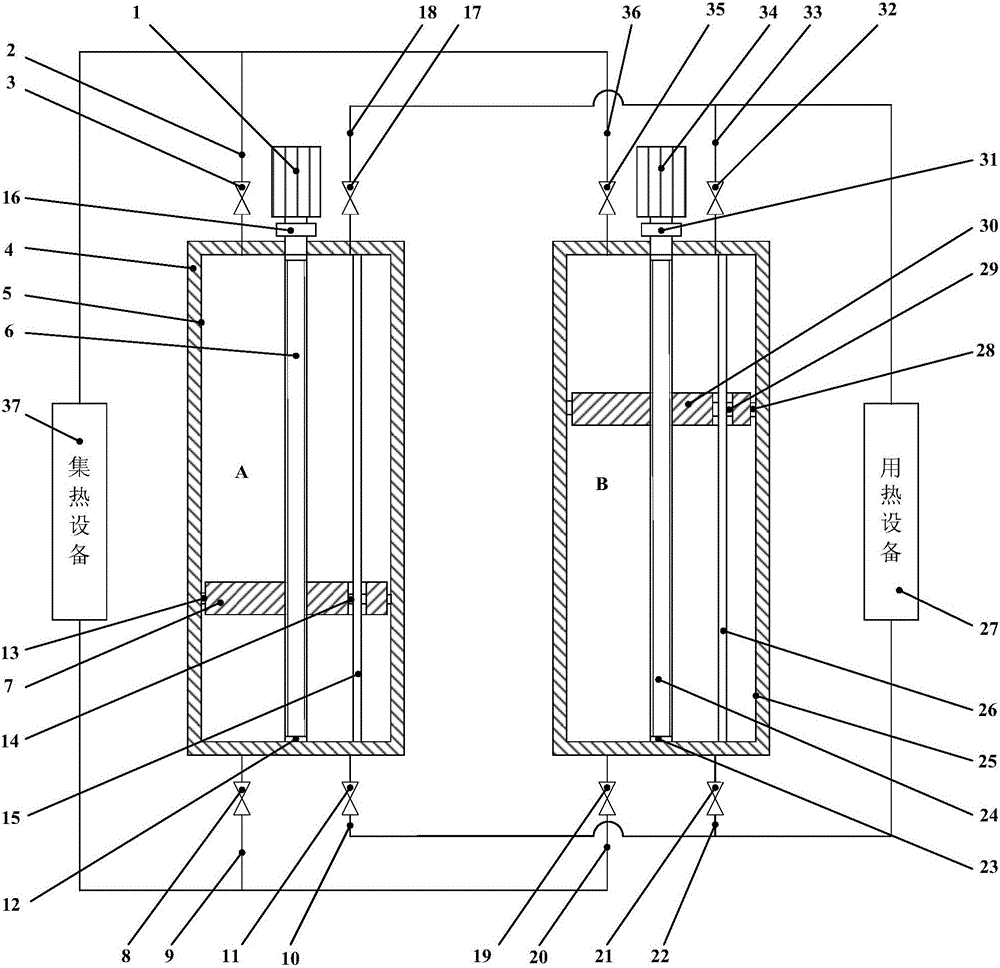

[0017] like figure 1 and figure 2 As shown, the temperature stratification device for liquid heat storage of the present invention consists of a frequency conversion motor 1, a hot fluid inlet 2, a hot fluid inlet valve 3, an insulation layer 4, a heat storage tank 5, a screw 6, a heat shield 7, a cold fluid Outlet valve 8, cold fluid outlet 9, cold fluid inlet 10, cold fluid inlet valve 11, screw bearing 12, heat shield seal ring 13, guide rod seal ring 14, guide rod 15, reducer 16, hot fluid outlet valve 17 And thermal fluid outlet 18 forms.

[0018] The insulation layer 4 is wrapped on the outer surface of the heat storage tank 5 to reduce the heat exchange between the heat storage tank 5 and the external environment. The frequency conversion motor 1, the reducer 16 and the screw rod 6 form the driving mechanism of the thermocline heat s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com