On-line rail vehicle bearing failure detection device and method

A detection device and bearing technology, which is applied in the field of rail transit, can solve problems such as laborious, complicated monitoring devices, and low detection efficiency, and achieve the effect of reducing the probability of bearing failure failure reporting and improving the failure detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

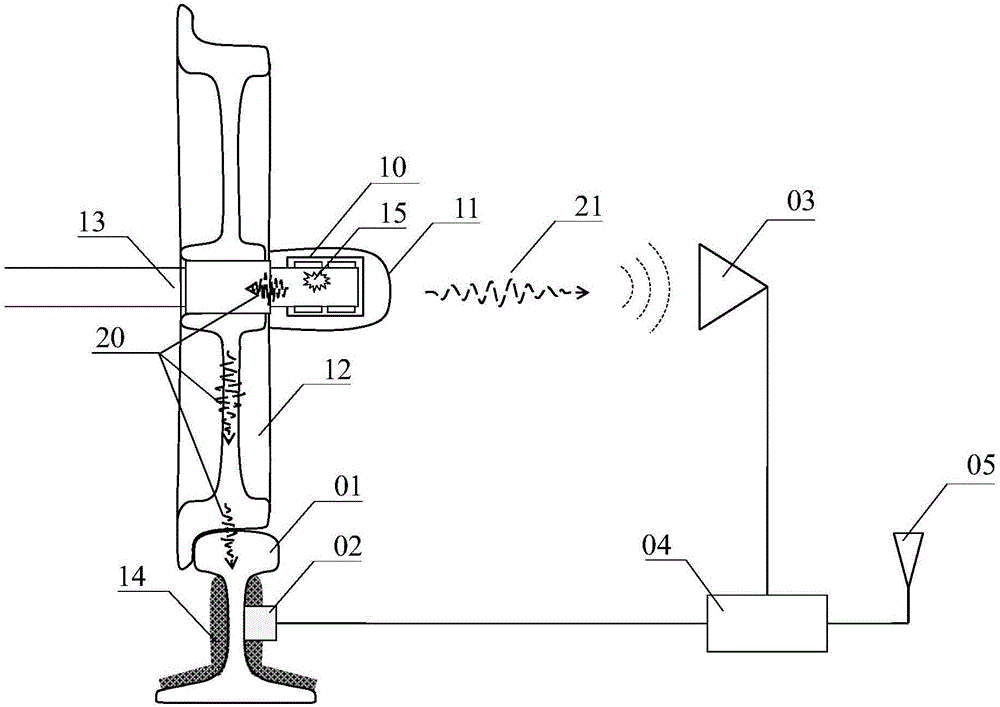

[0055] see figure 1 , the present invention provides an on-line detection device for rail vehicle bearing faults, the on-line detection device for rail vehicle bearing faults includes: a low-noise track 01, the low-noise track 01 is located on the path passed by the rail vehicle to be detected; Sensing module 02, described vibration sensing module 02 comprises at least one vibration sensor unit and signal output terminal, and described vibration sensing module 02 is positioned on described low-noise track 01, is suitable for collecting the rail vehicle to be detected Bearing fault solid-state sound signal; microphone module 03, the microphone module 03 includes at least one microphone unit and a signal output end, the microphone module 03 is located on the side of the low-noise track 01 and close to the position of the vibration sensing module 02 , being suitable for collecting the bearing fault airborne acoustic signal of the rail vehicle to be detected; the data processing m...

Embodiment 2

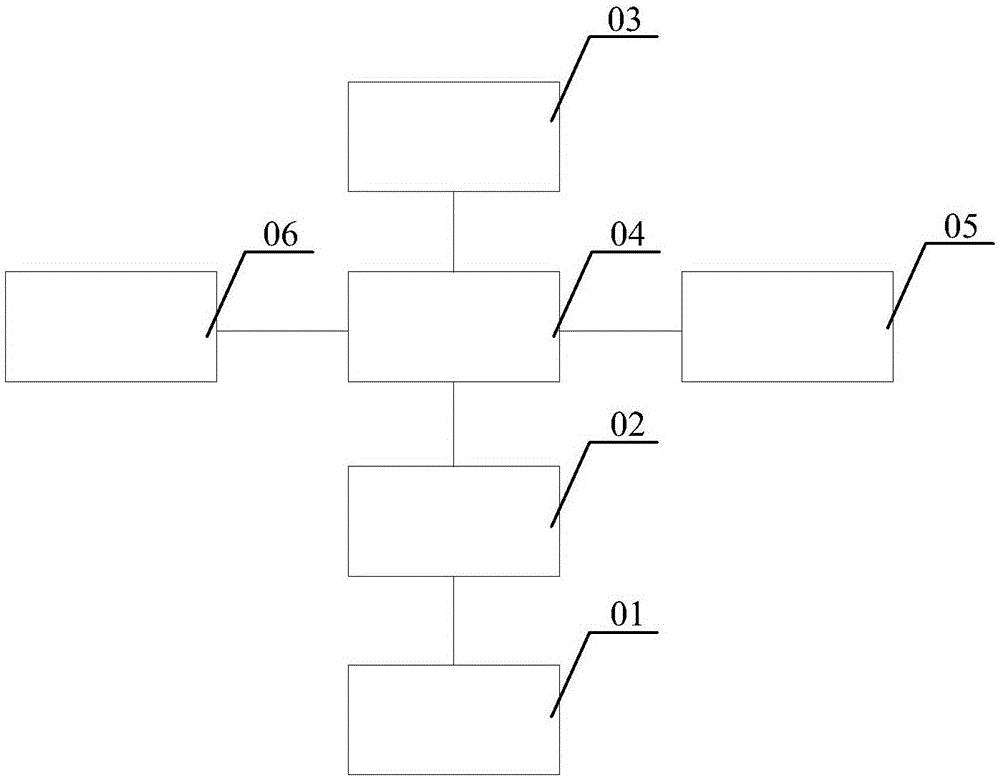

[0066] see Figure 4, this embodiment also provides an online rail vehicle bearing fault detection device, the rail vehicle bearing fault online detection device includes: a low-noise track 01, the low-noise track 01 is located on the path of the rail vehicle to be detected Vibration sensing module 02, the vibration sensing module 02 includes at least one vibration sensor unit and a signal output terminal, the vibration sensing module 02 is located on the low-noise track 01, and is suitable for collecting the track to be detected The solid-state sound signal of the bearing fault of the vehicle; the microphone module 03, the microphone module 03 includes at least one microphone unit and a signal output end, the microphone module 03 is located on the side of the low-noise track 01 and close to the vibration sensing module 02 The position is suitable for collecting the bearing fault airborne sound signal of the rail vehicle to be detected; the data transmission module 05 includes...

Embodiment 3

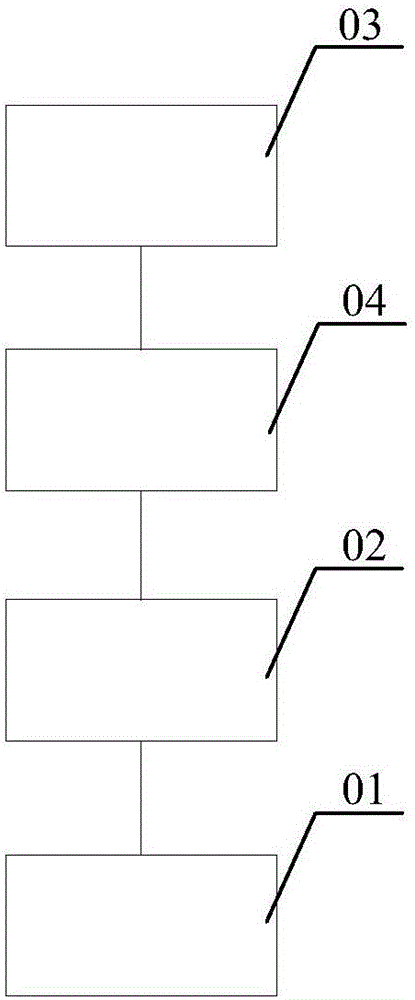

[0076] see Figure 6 , the present embodiment provides an online detection method for rail vehicle bearing faults, the detection method is based on the online detection device for rail vehicle bearing faults described in Embodiment 1 or Embodiment 2, and the detection method includes the following steps:

[0077] 1) When the rail vehicle to be detected passes through the low-noise track, use the vibration sensing module to collect the bearing fault solid-borne sound signal of the rail vehicle to be detected, and use the microphone module to collect the solid-state sound signal of the rail vehicle to be detected. Detection of bearing fault aeroacoustic signals of rail vehicles;

[0078] 2) Using the data processing module to determine the probability of a bearing failure by evaluating the correlation between the bearing failure solid-borne sound signal and the bearing failure air-acoustic signal.

[0079] As an example, as a preferred solution of the rail vehicle bearing fault...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com