Test system and test method for accelerating optical damp-heat aging for optical high molecular material

A polymer material, damp heat aging technology, applied in the direction of analysis materials, measuring devices, scientific instruments, etc., can solve the problems of high test cost and lack of universality of measurement data, and achieve shortening of aging time, effective blue light radiation total amount, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

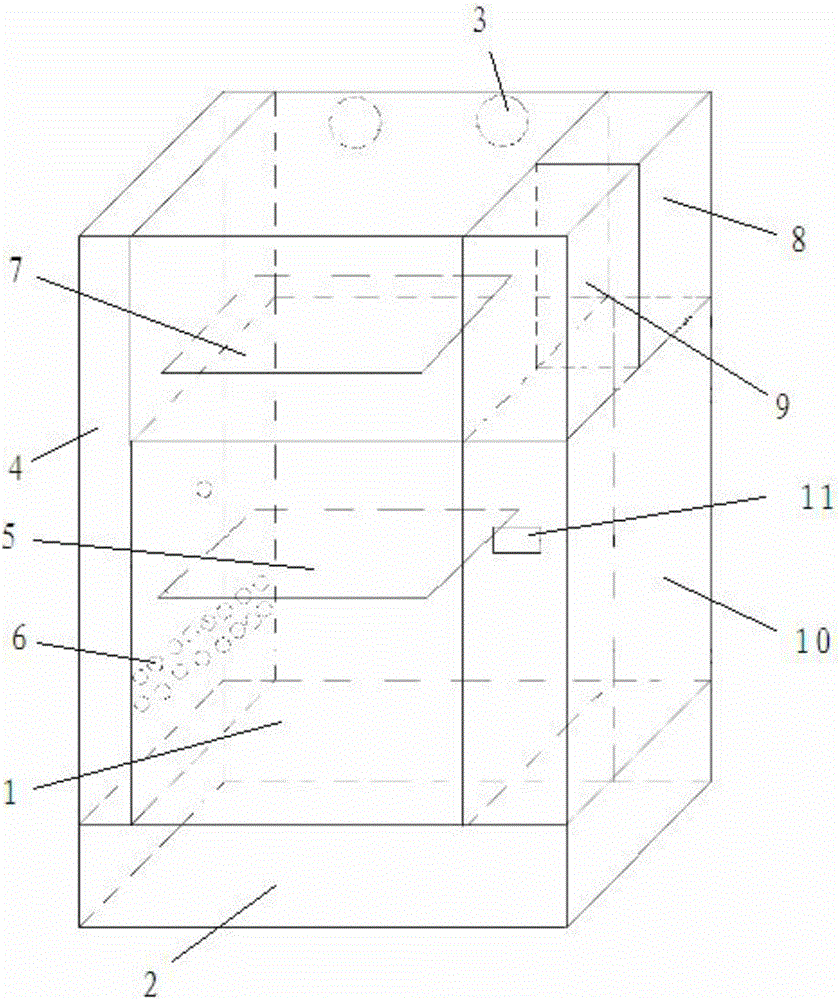

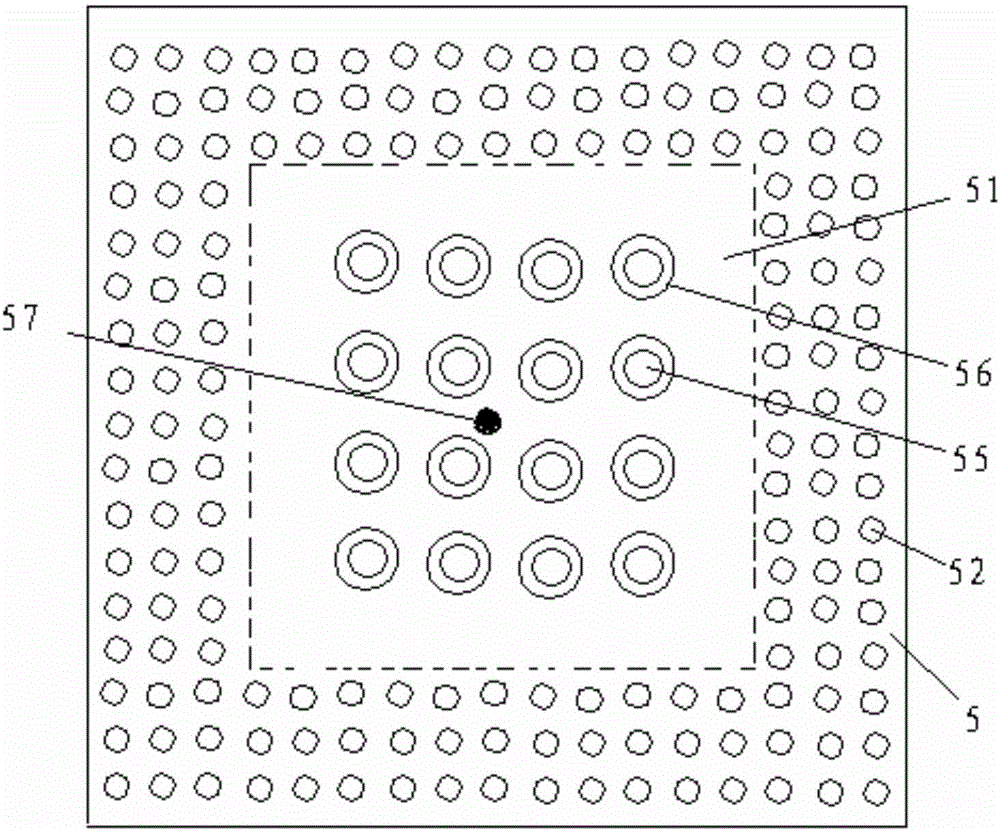

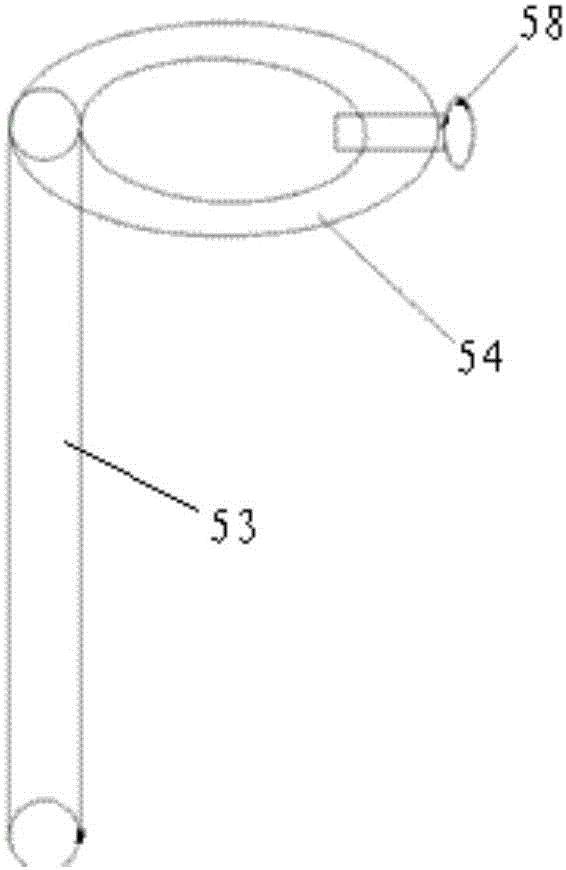

[0033] combine figure 1 As shown, a photomoisture-heat aging accelerated test system for optical polymer materials has a constant temperature and humidity test box 1, the side of the constant temperature and humidity test box 1 is provided with a test hole 6, and the outside of the constant temperature and humidity test box 1 is equipped with There is an iron cover 4 to improve the stability of the test conditions. The inner surface of the constant temperature and humidity test chamber 1 is coated with a layer of light-absorbing material, and a blue light source panel 7 is arranged inside the constant temperature and humidity test chamber, and the blue light source panel 7 is close to the top of the constant temperature and humidity test chamber 1. A plurality of luminous light sources are evenl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com