Video measurement based quantitative background schlieren method

A video measurement and background technology, which is applied in the field of flow display and aero-optical testing, can solve the problems of large deflection and displacement mutation range of background spots, difficulty in extracting data, and reduced offset accuracy, so as to overcome the adverse effects of measurement accuracy, High-accuracy measurement results and improved robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] A quantitative background schlieren method based on video measurement, comprising the steps of:

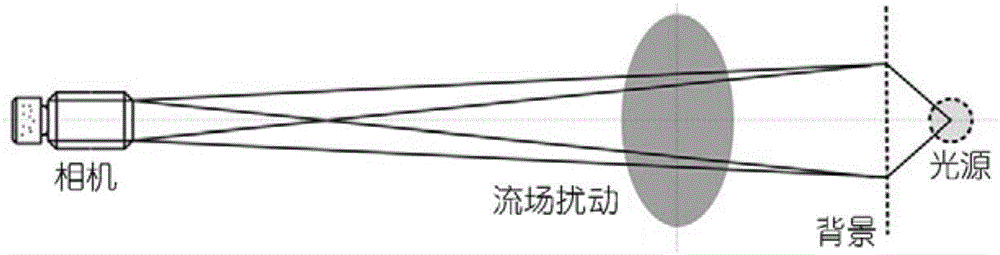

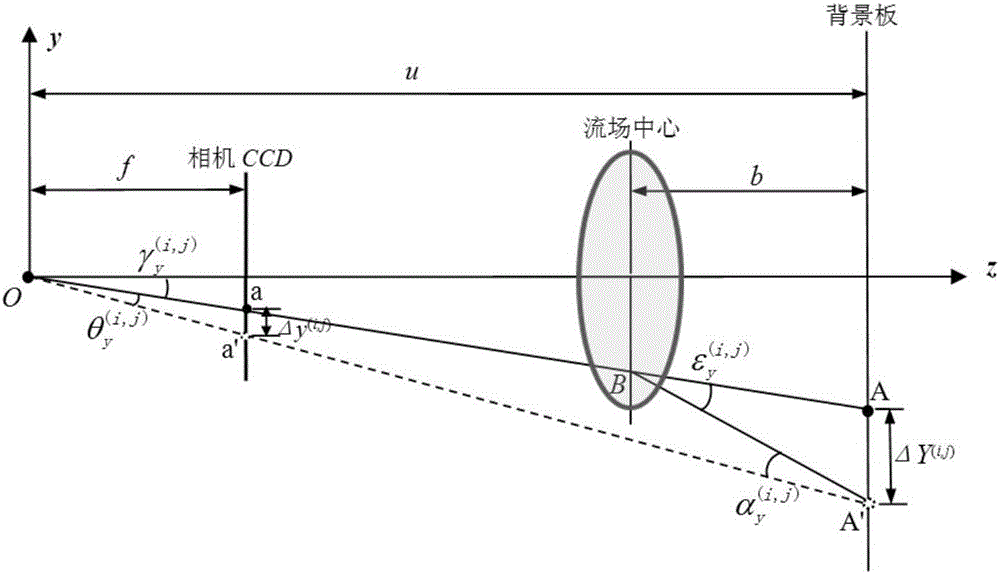

[0048] 1. Press figure 1 The principle shown to build a BOS system requires a background board and figure 2 The Z axis shown is vertical, and small dots with row and column intervals of S are arranged on the background board, and the diameter of the small dots is Φ D . The design method for a given dot A on the background board is as follows:

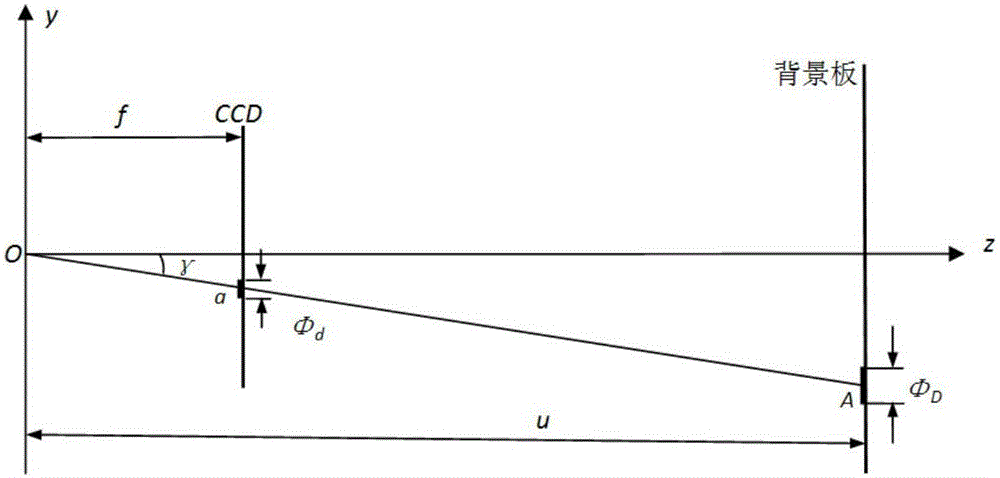

[0049] 1) if image 3 As shown, the diameter of point A

[0050] Φ D =uΦ d / f (1)

[0051] where Φ d is the diameter of the dot a on the camera imaged by the dot on the background plate, requiring Φ dMore than or equal to 6 pixels to ensure that the point positioning accuracy of small dot imaging is as high as 0.02 pixels. u is the distance from the background plate to the camera photography center O, and f is the focal length.

[0052] 2) Row and column spacing of dots

[0053] S=us / f (2)

[0054] In the formula, s is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com