Method for automatically detecting failure of insulator

An automatic detection and insulator technology, applied in measurement devices, optical testing of flaws/defects, material analysis by optical means, etc., can solve the problem of inability to clearly observe the surface condition of insulators, low resolution of insulator string images, and automatic detection functions. limited and other problems, to achieve a good use prospect, reduce workload, and reduce potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

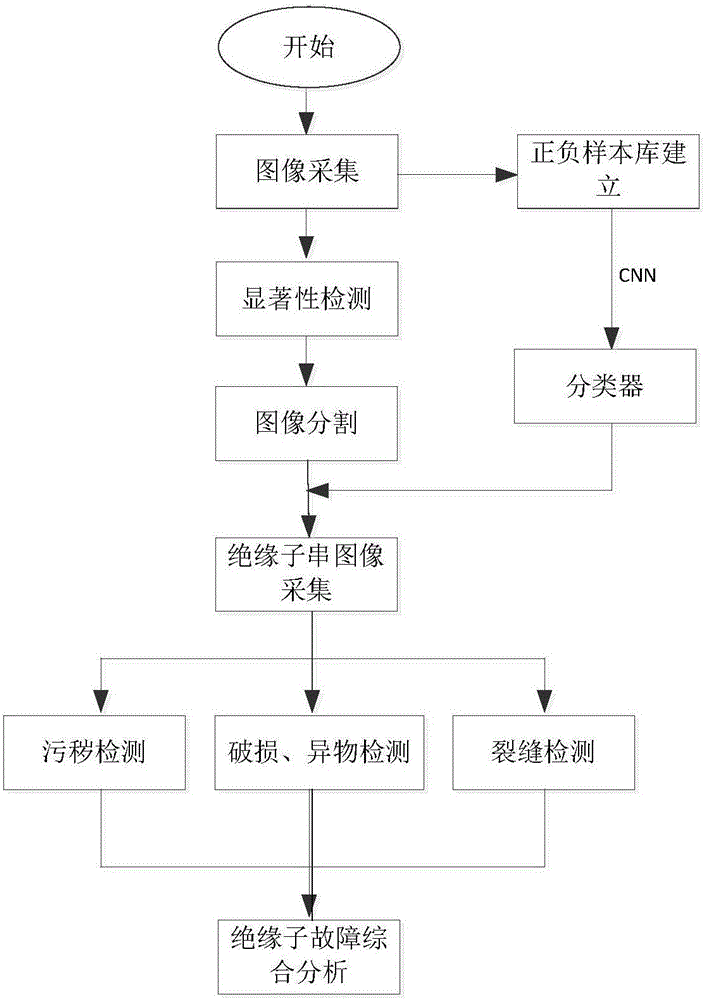

[0049] Such as figure 1 As shown, an insulator fault automatic detection method includes the following steps:

[0050] (1) Establish a positive and negative sample library of insulator images, and train an insulator classifier through a convolutional neural network algorithm (CNN);

[0051] (2) For the visible light image collected by the current robot, the image is segmented using the image salient area detection algorithm, the equipment area and the background area in the image are separated, and the insulator search candidate area is obtained;

[0052] (3) Use the CNN classifier to locate the insulator, and the visual servo system controls the image acquisition device to complete the image acquisition of the insulator string according to the location information of the insulator string in the current image;

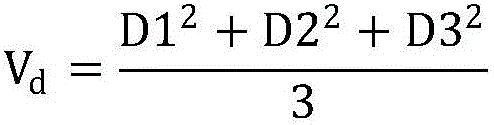

[0053] (4) Different image processing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com