Servo motor endurance test device and test method thereof

A servo motor and testing device technology, applied in the direction of motor generator testing, etc., can solve the problems that the tested product cannot be operated under high load, the durability effect of the servo motor is not obvious, and the durability cannot be tested at the same time, so as to achieve enhanced durability testing effect, the accuracy of durability test results, and the effect of improving durability test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

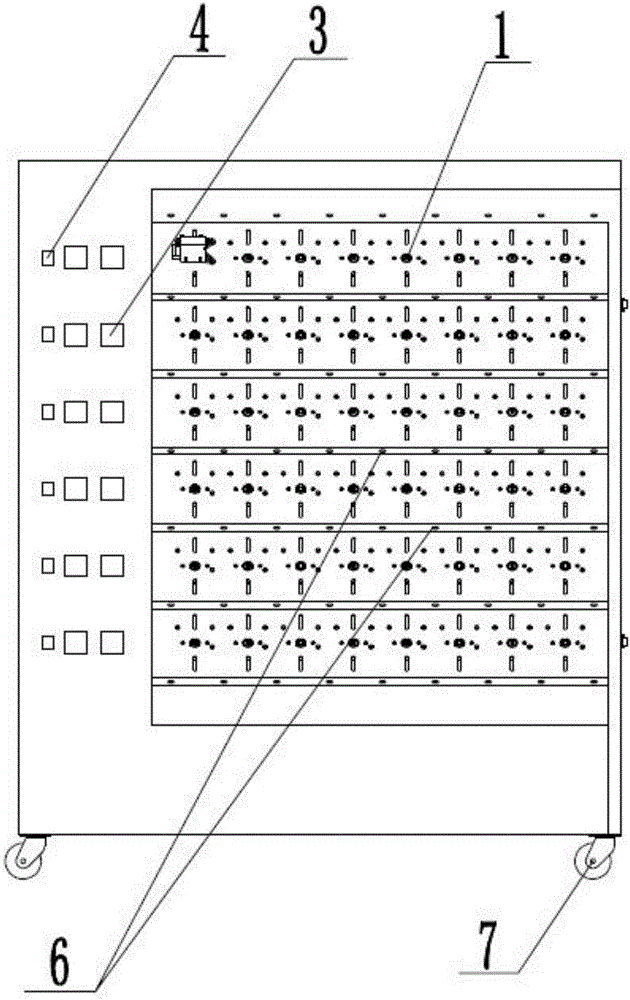

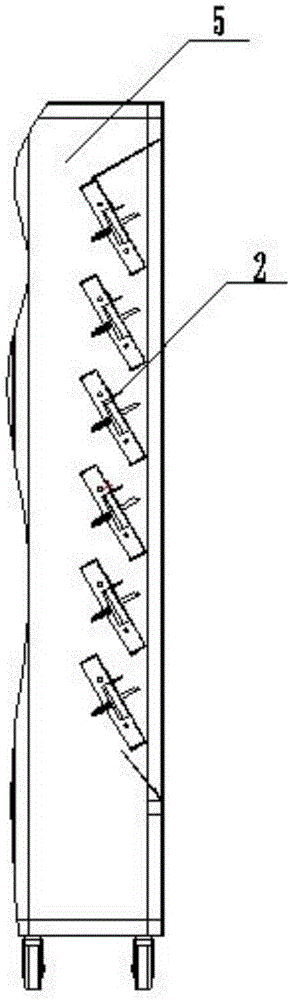

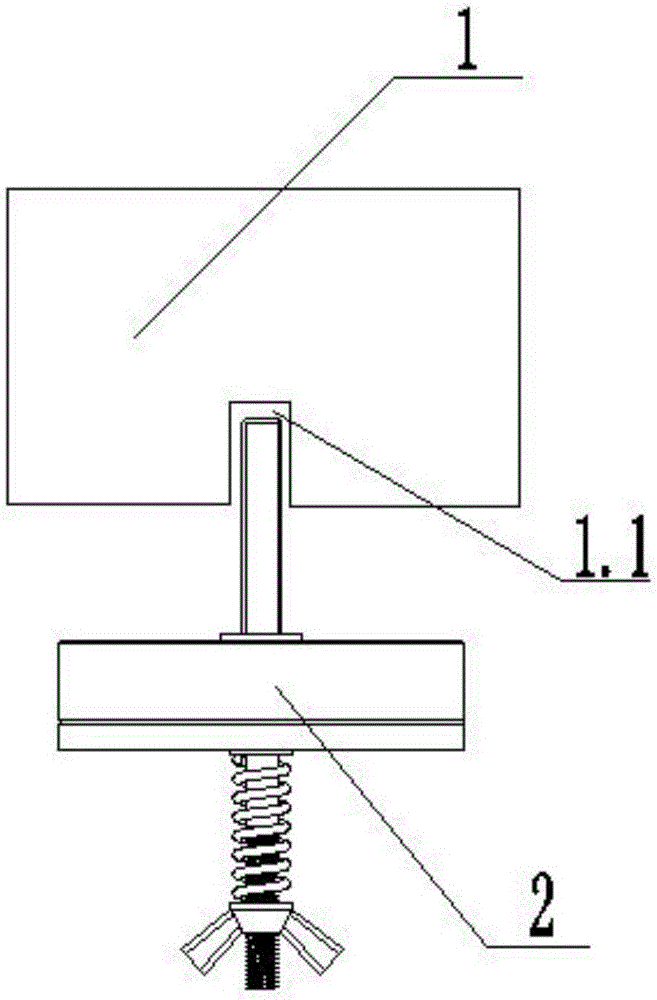

[0033] Such as Figure 1~4 As shown, a servo motor durability test device includes a servo motor 1, a mechanical load assembly 2 for providing the load required by the servo motor 1, and a power supply device 4. The output shaft 2.1 of the mechanical load assembly 2 and the servo The input hole 1.1 of the motor 1 is connected, and the power supply device 3 is electrically connected with the plug of the servo motor 1. The output shaft 2.1 of the mechanical load assembly 2 is sequentially installed with rolling bearing 2.2, bearing seat 2.3, friction plate 2.4, spring 2.6 and adjusting nut 2.7. The friction plate 2.4 and bearing seat 2.3 can be adjusted by adjusting the adjusting nut 2.7. The friction between the two, so as to control the output load of the output shaft 2.1 on the mechanical load assembly 2. To test the durability of the servo motor 1 under different load conditions, only need to adjust the friction between the friction plate 2.4 and the bearing seat 2.3 to outp...

Embodiment 2

[0037] Such as Figure 1~4 As shown, the present invention provides a servo motor durability test device, including a servo motor 1, a mechanical load assembly 2 for providing the load required by the servo motor 1, and a power supply device 4, the output shaft of the mechanical load assembly 2 2.1 is connected to the input hole 1.1 of the servo motor 1, and the power supply device 3 is electrically connected to the plug of the servo motor 1. The output shaft 2.1 of the mechanical load assembly 2 is sequentially installed with rolling bearing 2.2, bearing seat 2.3, friction plate 2.4, spring 2.6 and adjusting nut 2.7. The friction plate 2.4 and bearing seat 2.3 can be adjusted by adjusting the adjusting nut 2.7. The frictional force between the two, so as to adjust the output load of the output shaft 2.1 of the mechanical load assembly 2.

[0038] The difference between the second embodiment and the first embodiment is that the second embodiment also includes a time relay 3, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com