A Method for Optimizing the Elastic Support Span of a Gearbox in a Wind Turbine

A wind turbine and elastic support technology, applied in multi-objective optimization, design optimization/simulation, geometric CAD, etc., can solve the problems of low-cost natural frequency, high quality, and large volume without considering the elimination of low-frequency resonance risks , Improve sports performance, improve the effect of dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

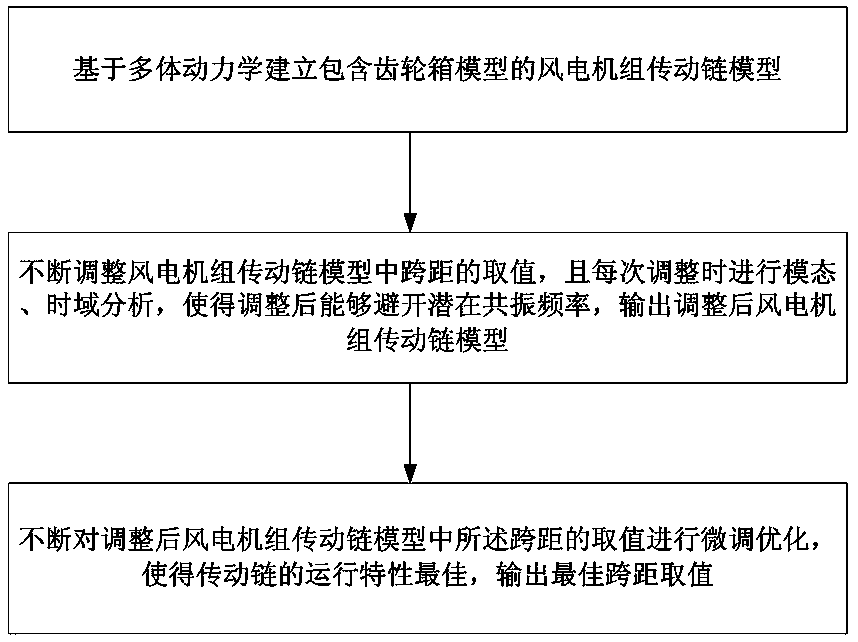

[0031] Such as figure 1 As shown, the method for optimizing the elastic support span of the gearbox in the wind turbine in this embodiment includes:

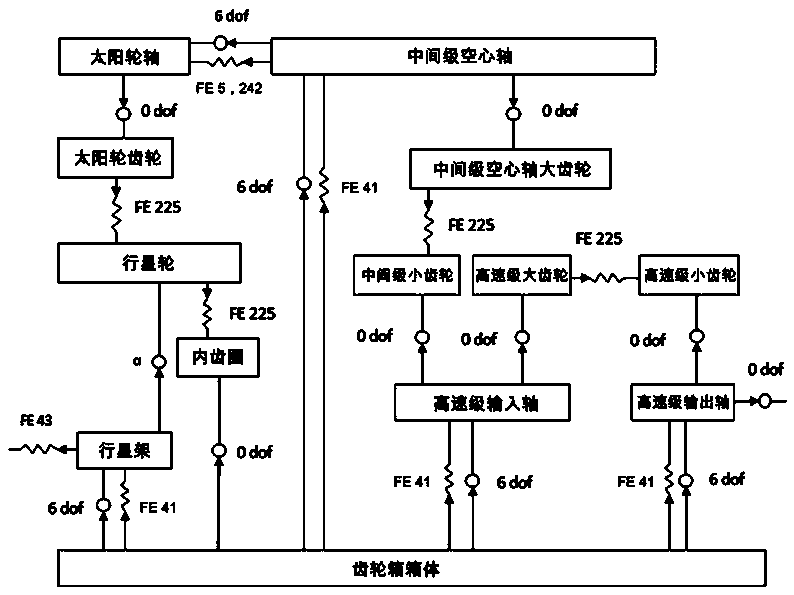

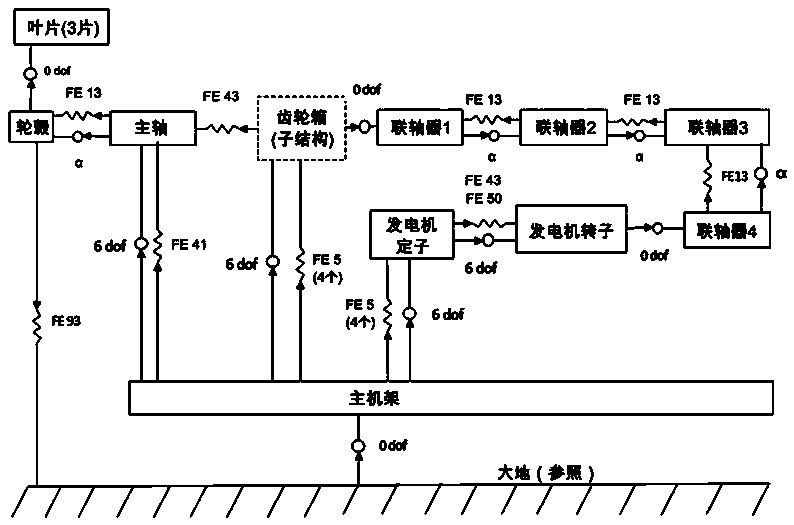

[0032] 1) According to the initial parameters of the target wind turbine, the transmission chain model of the wind turbine including the gearbox model is established based on multi-body dynamics. The initial parameters include the initial value of the span of the elastic support of the gearbox;

[0033] 2) Constantly adjust the value of the span in the transmission chain model of the wind turbine, and perform modal and time-domain analysis every time it is adjusted, so that the potential resonance frequency obtained by the modal and time-domain analysis can be avoided after adjustment, and the output adjustment D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com