A parallel bundled overhead insulated cable and its production process

An overhead insulated cable and production process technology, applied in the direction of insulated cables, insulated conductors, flexible cables, etc., to achieve the effects of high tensile strength, increased current carrying capacity, and high insulation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

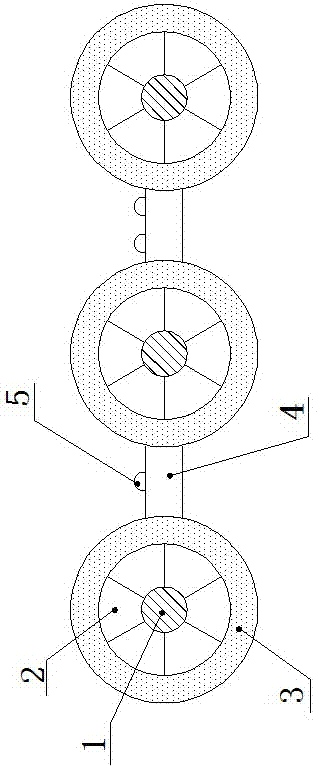

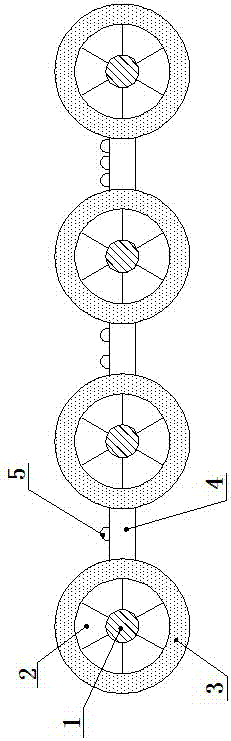

[0019] Such as figure 1 or figure 2 As shown, a carbon fiber reinforced core aluminum conductor parallel cluster overhead insulated cable, it includes a compacted conductor, and the compacted conductor is made of a round carbon fiber wire 1 and a special-shaped duralumin wire arranged on the outer wall of the round carbon fiber wire 1 2 twisted, the outer wall of the compressed conductor is provided with an insulating layer 3, the insulating layer 3 is connected with a connecting rib 4, and the upper side of the connecting rib 4 is provided with a Peugeot wire 5.

[0020] The present invention is a 3-core or 4-core parallel cluster overhead cable, which has the following advantages when used: 1. High tensile strength, ① Due to the use of circular carbon fiber filaments, the overall breaking force of the cable can be greatly improved, and the installation of the cable can be increased. spacing, to meet special requirements and reduce installation costs; ②The quality is relati...

Embodiment 2

[0022] A production process of parallel bundled overhead insulated cables, the production process of the parallel bundled overhead insulated cables includes the following steps: Step 1: wire drawing, using a wire drawing machine, and through an improved drawing die, drawing according to the conductor stranding structure Make profiled aluminum monofilaments; step 2: stranded wires, use carbon fiber filaments as the load-bearing wire and the profiled aluminum monofilaments obtained in step 1 are arranged according to a certain structure and then concentrically twisted to form a conductive core, and a diamond mold is used Carry out secondary round compaction; Step 3: Extrusion, use the polyethylene material after irradiation cross-linking to extrude the conductor wire core through an extruder; Step 4: Cross-linking, use the insulating material obtained in Step 3 The conductor wire core of the first layer is irradiated and cross-linked; the cross-linking time is 2-4h.

[0023] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com