A silicon chip serial welding and feeding device capable of automatic deviation correction

An automatic deviation correction, silicon wafer technology, applied in auxiliary devices, welding equipment, transportation and packaging, etc., can solve the problems of cumbersome operation steps, inability to accurately adjust the angle of silicon wafers, complex structure, etc., to achieve uniform adsorption force, improved precision, Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

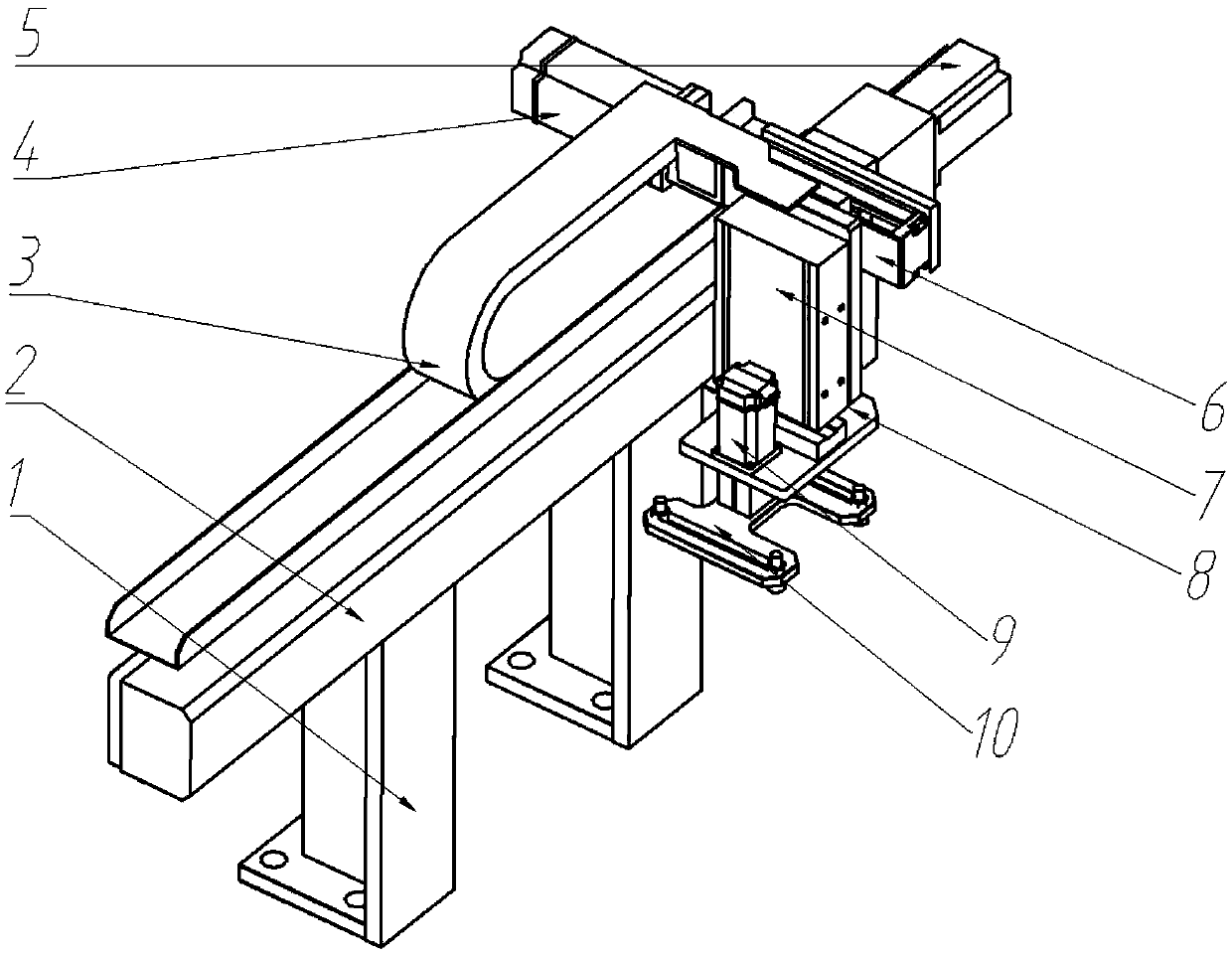

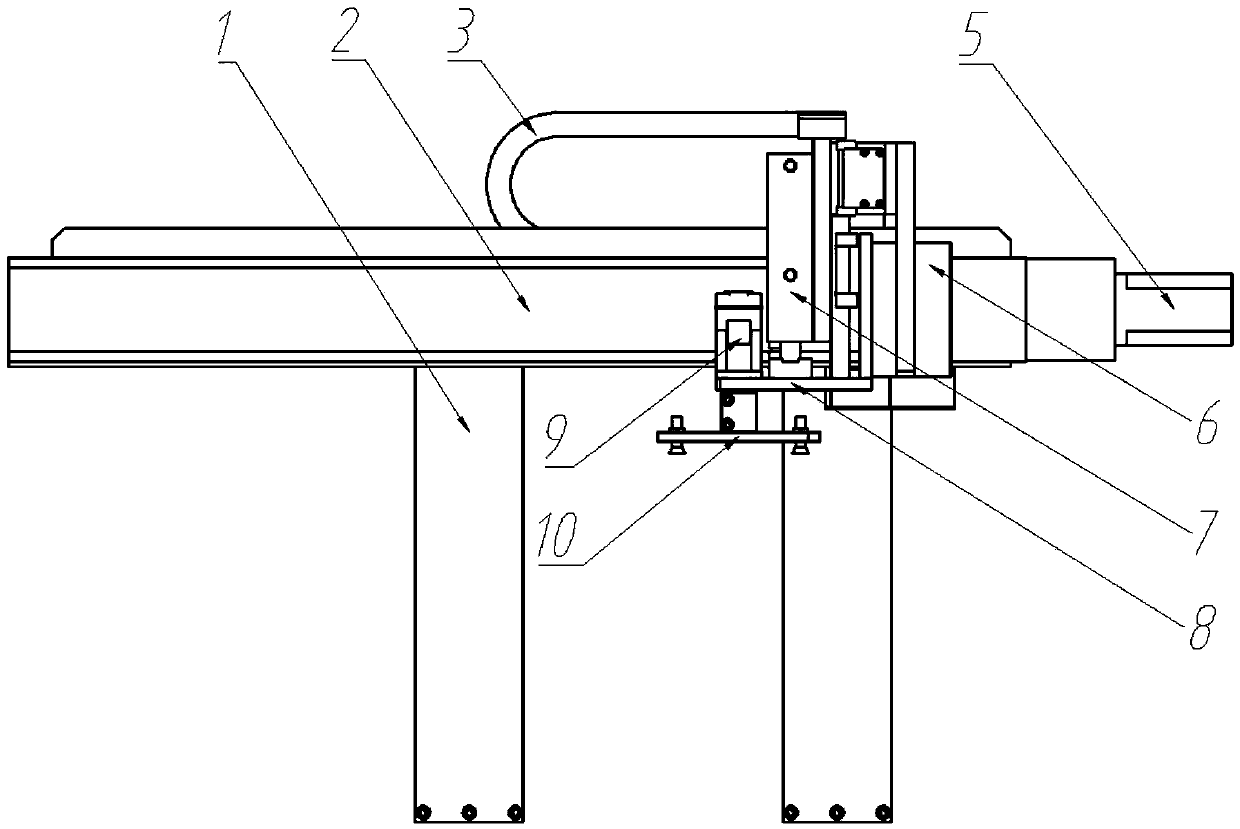

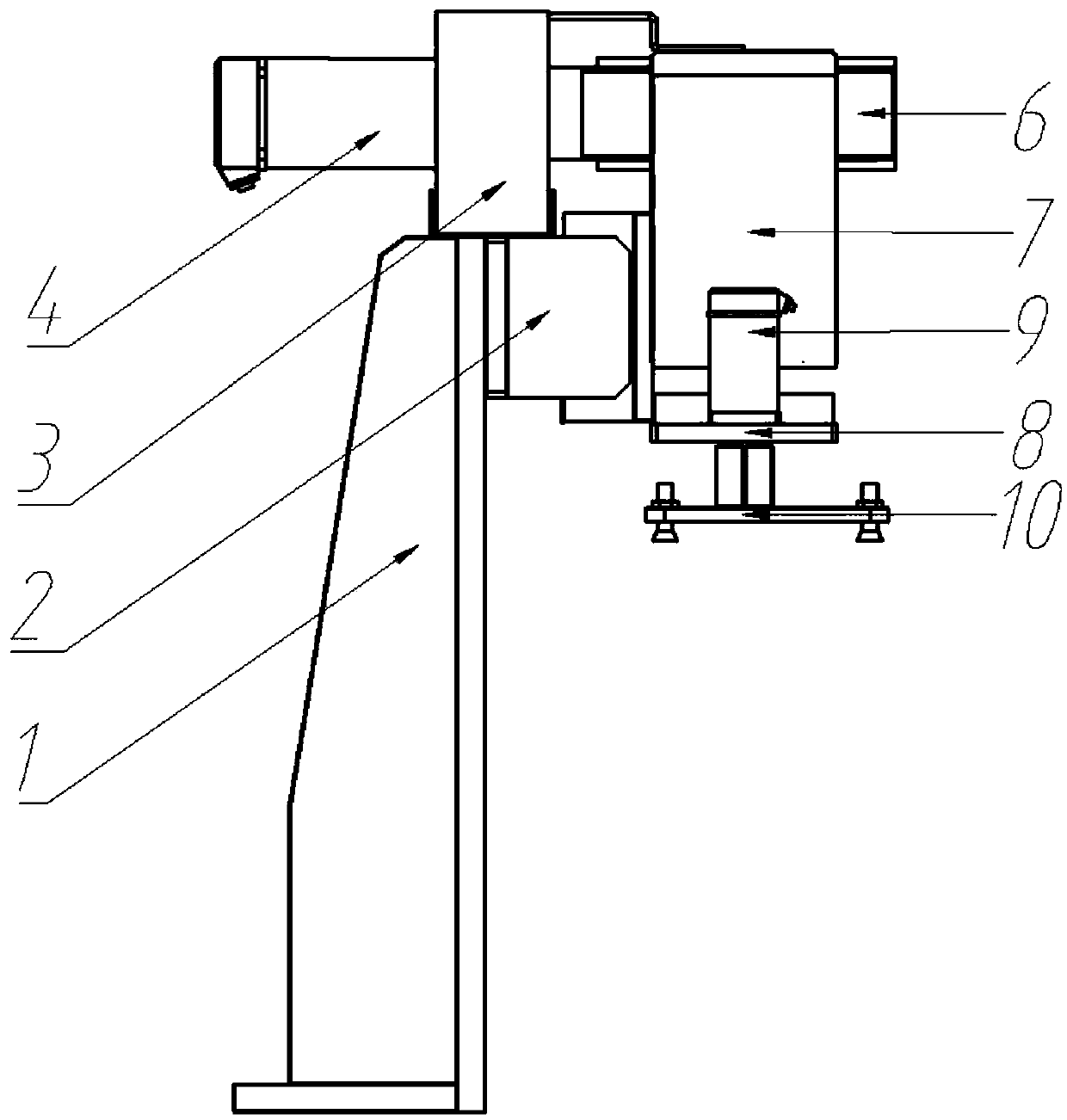

[0023] Embodiment: A silicon wafer serial welding and loading device capable of automatic deviation correction.

[0024] refer to Figure 1 to Figure 4 As shown, a silicon wafer serial welding and feeding device capable of automatic deviation correction includes: a support frame 1, a horizontal moving guide rail 2, a cable protection chain 3, a longitudinal position adjustment motor 4, a horizontal position adjustment motor 5, and a longitudinal moving guide rail 6 , cylinder 7, grip support plate 8, angle position adjustment motor 9 and negative pressure retractable grip 10. The horizontal moving guide rail 2 is installed on the top of the support frame 1 through the connecting plate. The number of the support frame 1 depends on the length of the horizontal moving guide rail 2. The longer the horizontal moving guide rail 2, the more the number of support frames 1. The horizontal moving guide rail 2 adjusts the motor in the horizontal position. Driven by 5, the negative press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com