Electromagnetic induction heating system and temperature detection method

An electromagnetic induction heating and heater technology, which is applied in the direction of induction heating, induction heating control, induction heating device, etc., can solve the problem of high-power switching element damage temperature control, etc., and achieve the effect of ingenious design and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

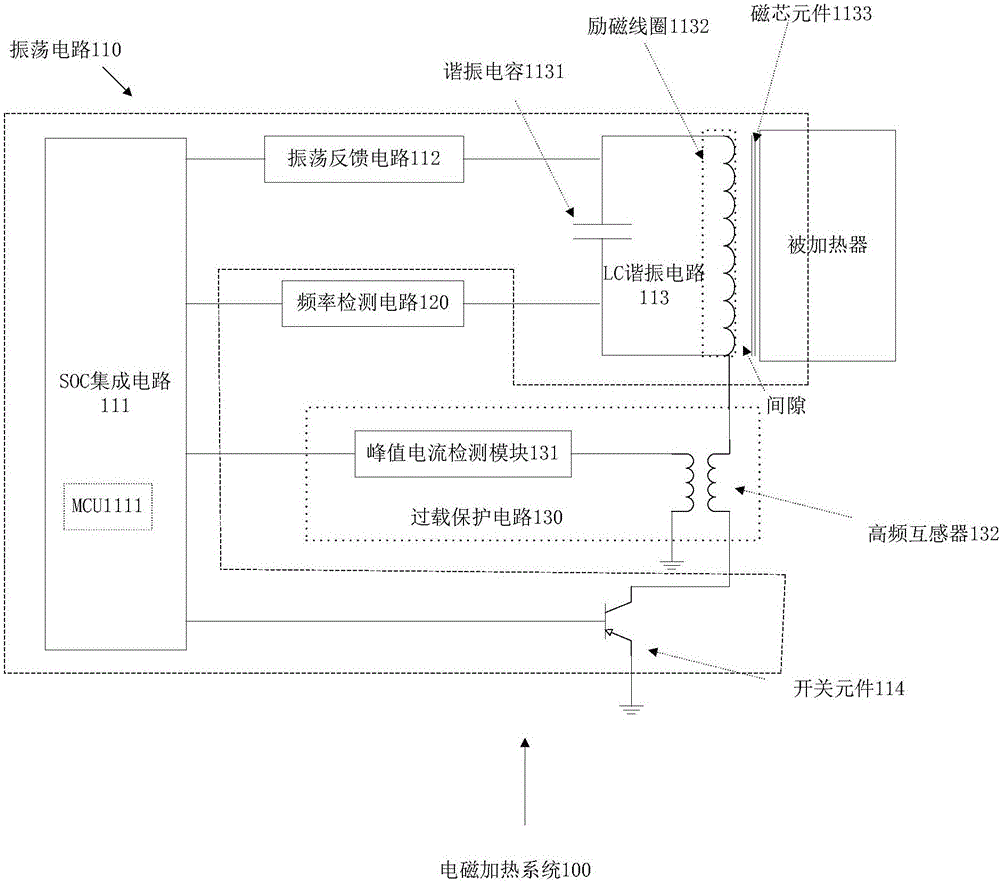

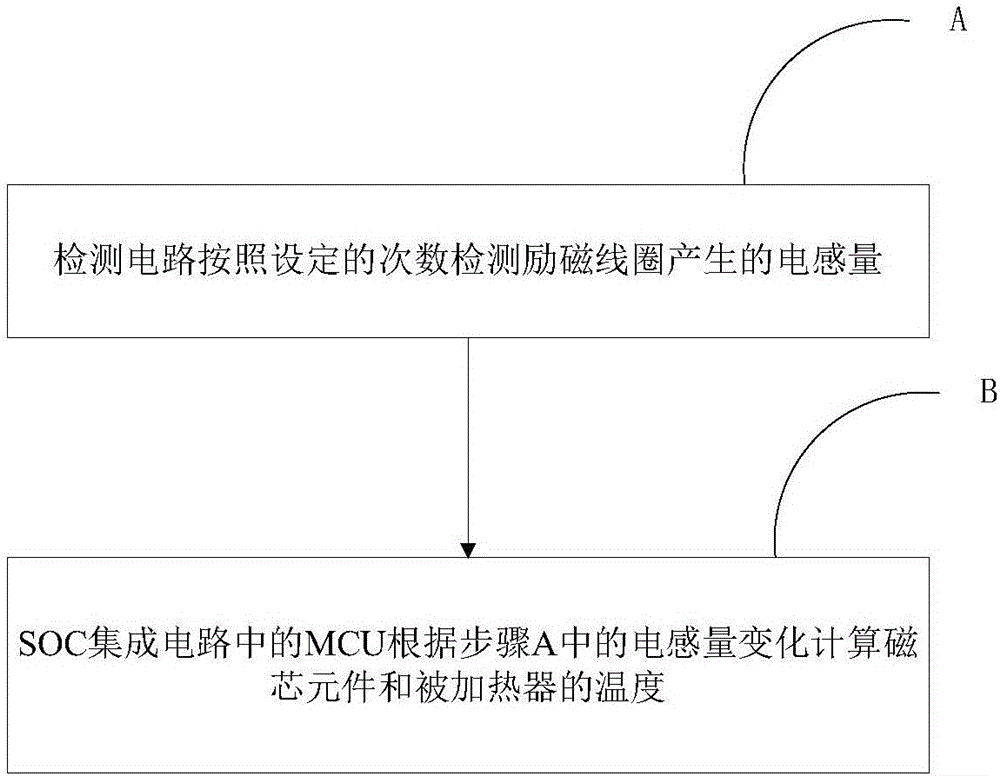

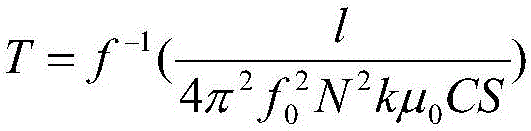

[0021] The technical problem to be solved by the present invention is: on the one hand, different magnetic core materials in the electromagnetic induction heating system have different magnetic permeability, and the magnetic permeability of some magnetic cores will also change correspondingly due to changes in temperature, and these changes will further It will affect the change of oscillation frequency of the electromagnetic induction heating system, and the change of resonance frequency will further affect the performance of high-power components: if the oscillation frequency changes sharply, it will cause fatal damage to high-power components. How to detect the change of magnetic core material It is a problem to be solved by the present invention to choose different heating methods, control some materials that are not suitable for heating, and avoid unnecessary damage to circuit components; It is also very important to say that temperature sensors are generally used in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com