Linear LED drive circuit for silicon controlled dimming

A technology of LED drive and drive circuit, applied in the direction of light source, electric light source, electrical components, etc., can solve the problem of switch flickering, etc., and achieve the effect of smooth and excellent dimming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

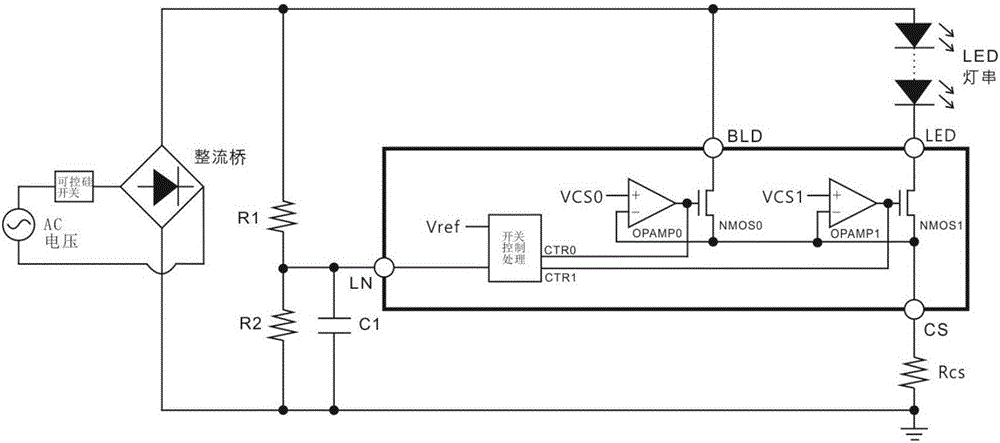

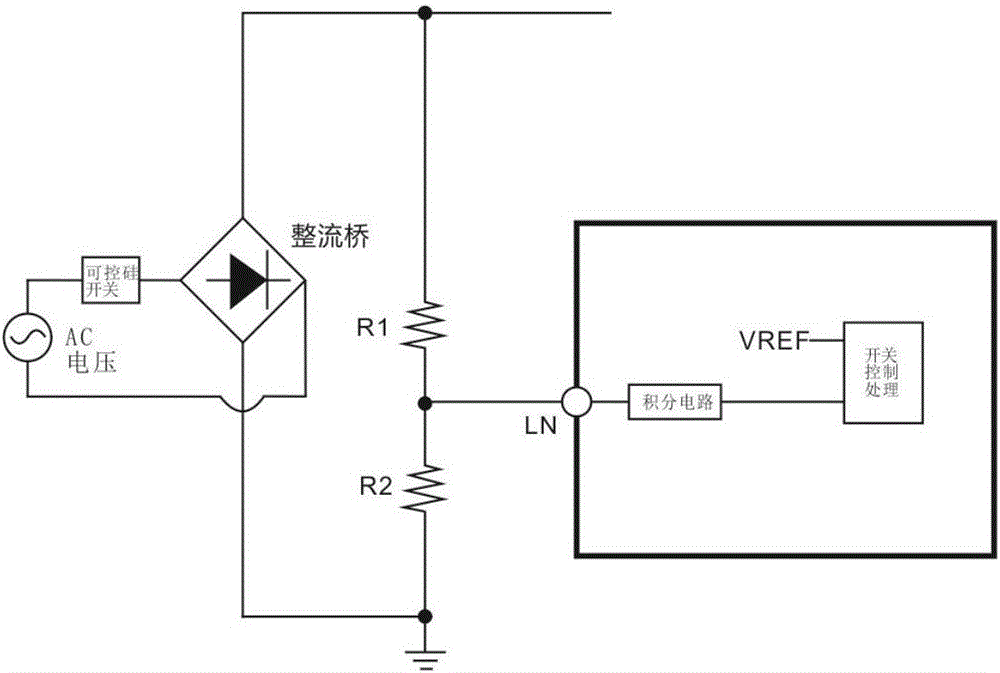

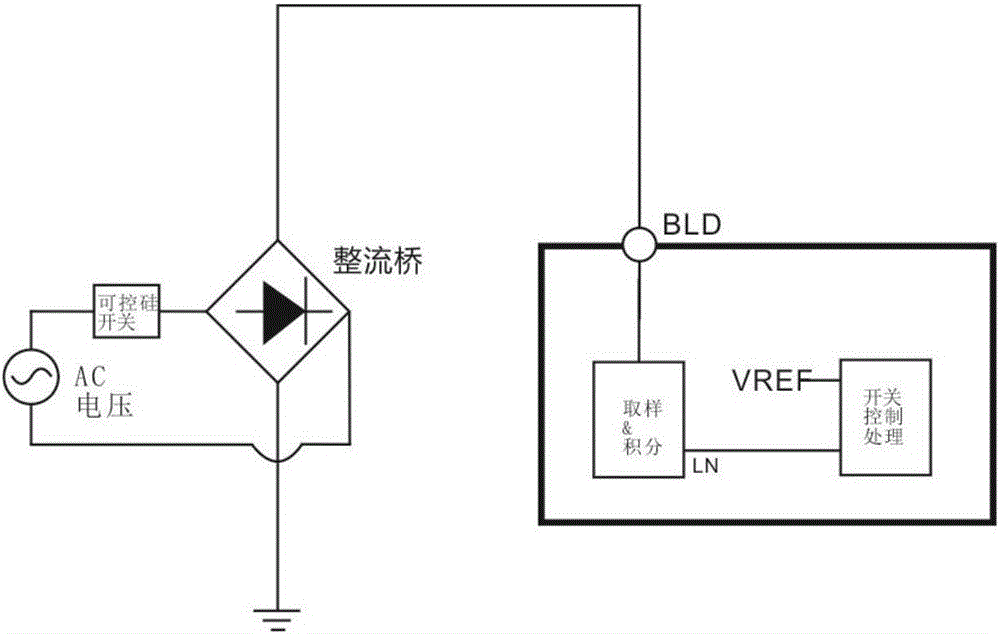

[0047] The main circuit adopted in the present invention includes a bus voltage sampling integration circuit, a bus voltage signal processing circuit, a thyristor maintaining current circuit, and an LED constant current control circuit.

[0048] like figure 1 As shown, R1 / R2 / C1 forms a bus voltage sampling integration circuit. The main function of this circuit is to divide the bus voltage and integrate it through RC to get a stable DC voltage and send it to the LN terminal. The signal LN will be used to control the switching control between the SCR maintaining current circuit and the LED constant current control circuit. The advantage of using the integral circuit is that it can effectively avoid the LED light from being turned on by mistake due to the surge voltage at the moment the thyristor is turned on, and it is easy to see the light flickering phenomenon. At the same time, during the dimming process, if there is no processing by the integrating circuit, the LED light w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com