Sludge mixer with feeding pressure monitoring function

A technology of pressure monitoring and mixer, which is applied in mixers, mixers with rotating stirring devices, dehydration/drying/thickened sludge treatment, etc., which can solve the problem of unsatisfactory mixing effect, the area occupied by sludge conditioning tanks and the Large investment and other issues, to achieve the effect of good mixing effect, fast speed and reasonable structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

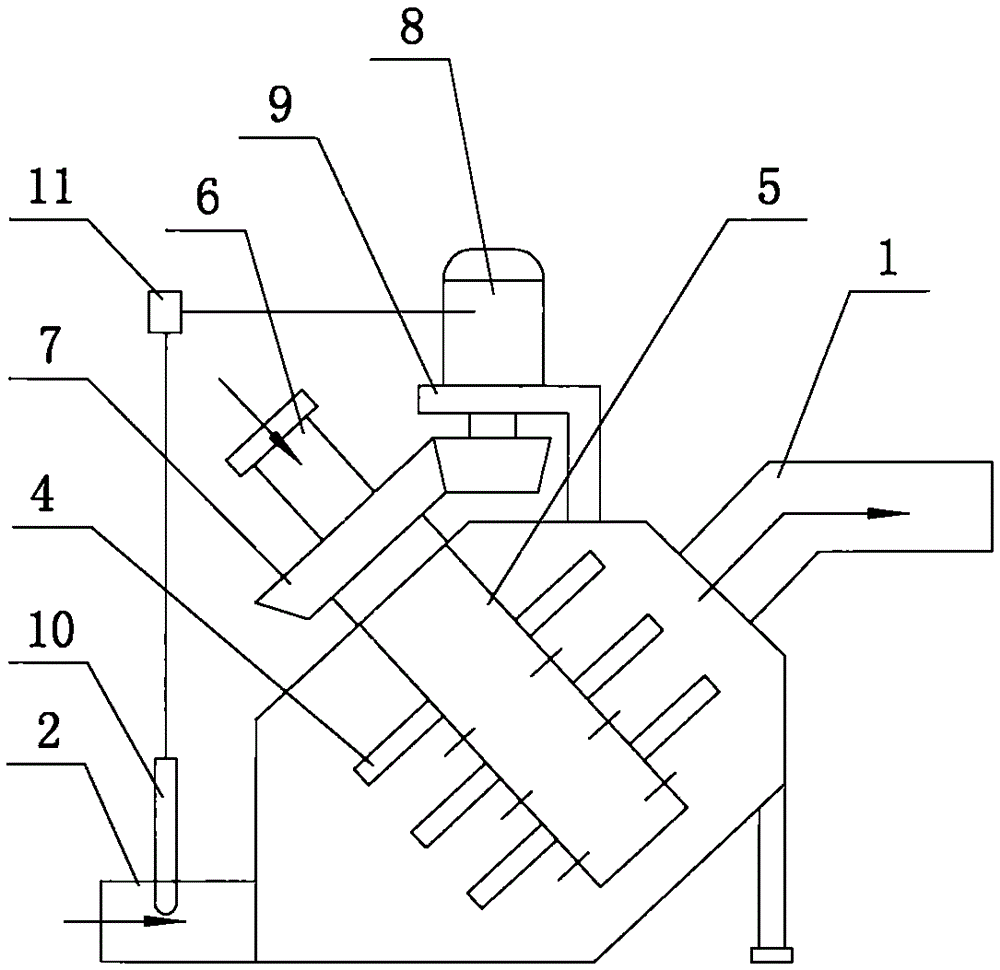

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] like figure 1 As shown, the sludge mixer with feed pressure monitoring in this embodiment includes a mixing kettle 1, and the mixing kettle 1 has a muddy water feed pipe 2 and a muddy water discharge pipe 3; a stirring device is provided in the mixing kettle 1, and the muddy water The feed pipe 2 is located at the bottom of one side of the mixing kettle 1, and the muddy water discharge pipe 3 is located at the top of the other side of the mixing kettle 1; Between the pipe 2 and the muddy water discharge pipe 3; the stirring shaft 5 has a hollow structure, and its side wall is provided with blades 4 and diversion holes at intervals, and the diversion holes are located between adjacent blades 4; the upper end of the stirring shaft 5 has a A flocculant feed pipe 6 is connected to a motor 8 through a bevel gear assembly 7, and the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com