Cell digester

A digester and cell technology, applied in the field of cell digester, can solve the problems of changing the biological characteristics of cells, cell damage, difficult cell seed preparation, etc., and achieve the effect of promoting adhesion and proliferation, reducing adverse effects, and shortening the digestion cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

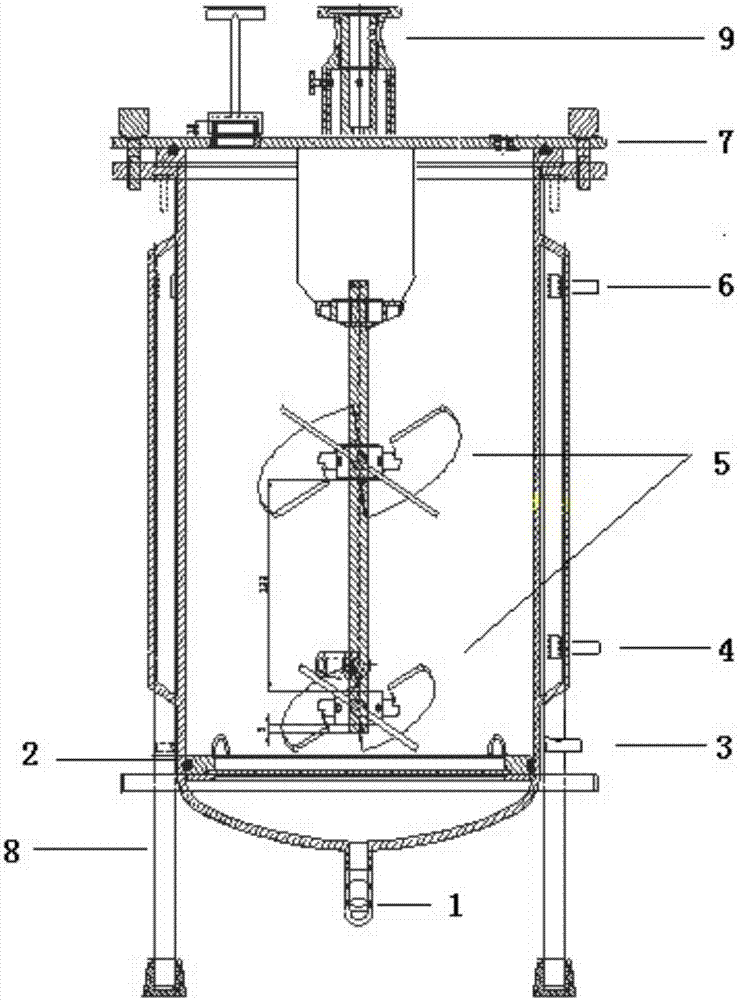

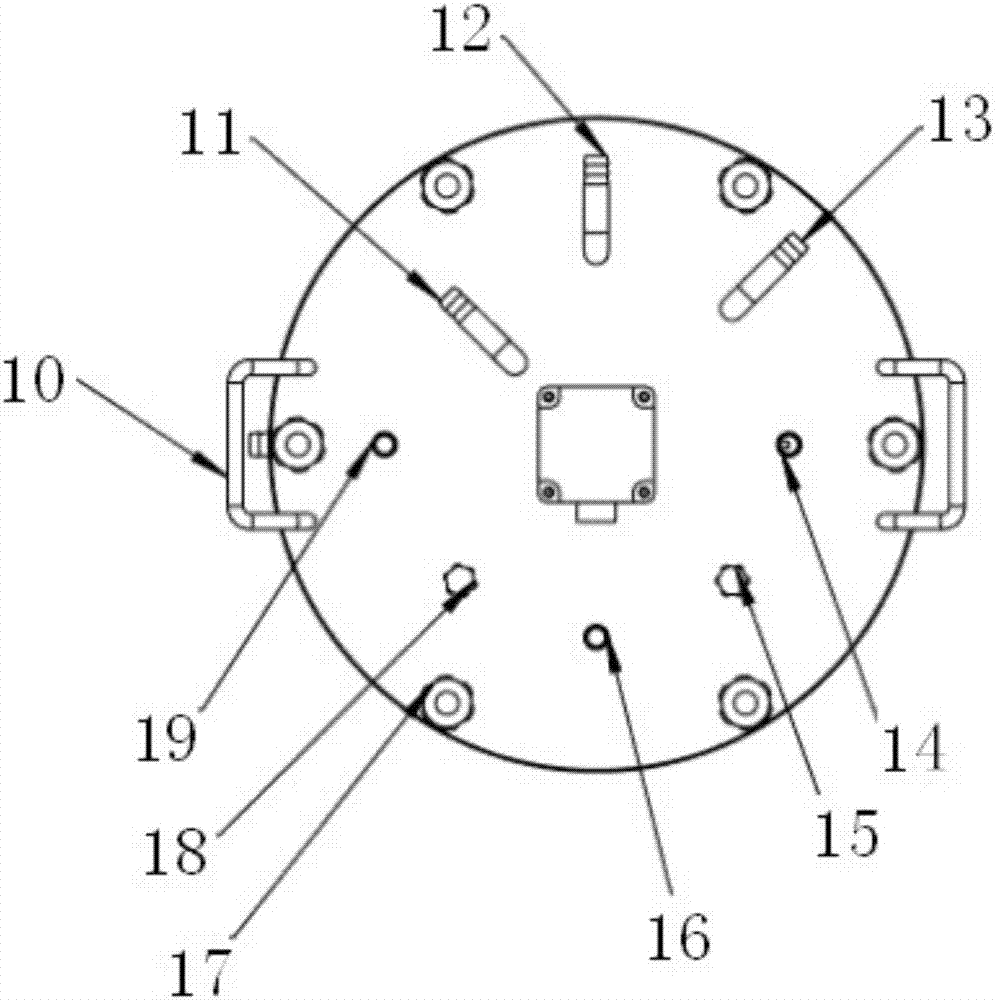

[0026] Example 1 Cell Digester

[0027] Such as figure 1 As shown, the cell digester is composed of a digestion tank, a bracket 8 for supporting the digestion tank, and a top cover 7 of the digestion tank. The digestion tank includes a tank body and a tank bottom. The material of the digestion tank is stainless steel, and the bottom of the tank is a cavity for collecting liquid. The lowest end of the cavity is provided with a liquid discharge port 1, and a detachable screen 2 is provided horizontally at the joint between the tank body and the bottom of the tank. The microcarrier or impurity mass is intercepted so that the cells flow into the cavity at the bottom of the tank; a sampling / recovery port 3 is set below the outer wall of the tank and above the connection between the tank body and the bottom of the tank.

[0028] The bottom surface of the tank bottom is a concave arc or triangle, and a liquid discharge port 1 is arranged at the bottom of the bottom surface of the ta...

Embodiment 2

[0037] Example 2 Preparation of primary cells (chicken embryo fibroblasts) using the cell digester of the present invention

[0038] 1) Select chicken embryonic leg muscles and breast muscles in a sterile environment, and remove epidermis, blood vessels and connective tissue. Wash the digested tissue with 0.02M PBS buffer and cut into 1mm 3 Small pieces, about 1L.

[0039] 2) Aseptically transfer the tissue to be digested into the cell digester (autoclaved) of Example 1, and add an equal volume of 0.25% trypsin solution. The sieve aperture selected in this embodiment is 75 μm.

[0040] 3) Connect an external temperature control system to maintain the digestion temperature at 37°C while stirring at a low speed.

[0041] 4) When the digestive system becomes turbid or the tissue to be digested becomes minced, collect the cell suspension through the bottom drain port, and transfer the cell suspension to another container for termination of digestion.

[0042] 5) Add an equal v...

Embodiment 3

[0048] Example 3 Scale-up of cell microcarrier suspension culture from 14L to 130L by using a cell digester.

[0049] 1) The cells are cultured in a 14L bioreactor (fermenter) for 3-5 days, and the cell culture is stopped when the cells grow into a dense monolayer on the microcarrier.

[0050] 2) Clean and assemble the main body of the cell digester and the auxiliary pipelines of the present invention, and perform high-pressure sterilization at 121° C. for 30 minutes in a high-pressure steam sterilization cabinet. After the sterilization is complete, allow the equipment to cool down to room temperature under laminar flow protection.

[0051] 3) Aseptically connect the harvesting pipeline of the bioreactor to the cell digester inlet of the cell digester, and transfer the microcarrier and medium with cells into the cell digester. At the same time, connect the drain port at the bottom of the cell digester tank to the waste liquid collection container. When the cells and medium a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com