Coating method

A coating method and coating technology, applied to coatings, devices for coating liquid on surfaces, special surfaces, etc., can solve problems such as long curing time of coatings in production areas, high volatile organic compounds, and atmospheric environment effects, and achieve environmental protection And easy to implement, increase the hardness and fullness of the paint film, and have a strong three-dimensional effect on the paint surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

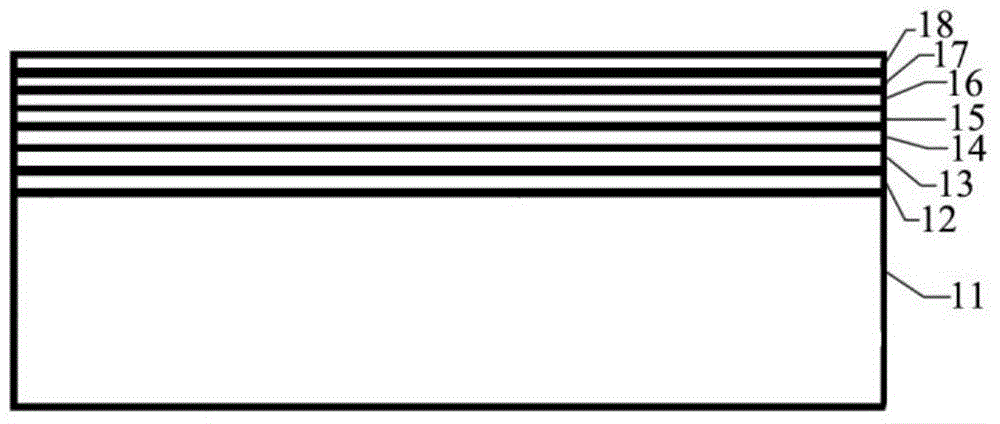

[0030] This embodiment provides an exemplary method for coating a planar piece, said method comprising the steps of:

[0031] 1) Use 80#, 100#, 120# sandpaper to sand the plain board respectively;

[0032] 2) Manually wipe the surface of the plain board treated in step 1) with UV-water-based color wiper, with an amount of 8-12g / m2 2 , drying by infrared rays at 70°C for 10 minutes,

[0033] 3) Use a putty roller coater to coat the UV-roller filling putty with an amount of 30-40g / m 2 , 150mJ / cm 2 After UV curing, polish with 240# sandpaper, and paint twice continuously to fill the wooden holes;

[0034] 4) Apply UV-roller sanding primer with a laser roller coater, with an amount of 30-40g / m 2 , leveling for 15 seconds, 80mJ / cm 2 UV semi-curing, the surface is slightly sticky;

[0035] 5) Use UV-laser roller to coat the primer with a laser roller coater, with an amount of 40-50g / m 2 ;Leveling for 15 seconds, 180mJ / cm 2 Polish with 400# sandpaper after UV curing;

[0036...

Embodiment 2

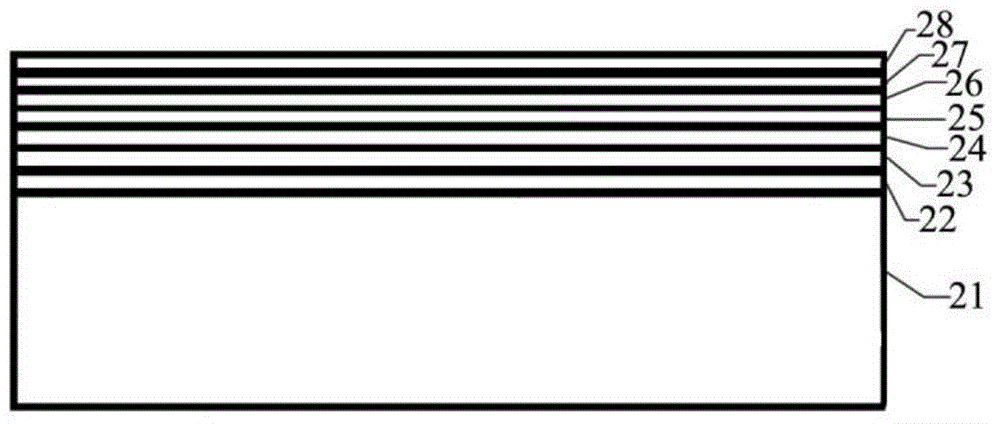

[0041] The present embodiment provides a kind of exemplary method that is used for coating planar parts, and its coating step is identical with embodiment 1, just UV-water-based coating is replaced with one-component water-based coating, and concrete steps are as follows:

[0042] 1) Use 80#, 100#, 120# sandpaper to sand the plain board respectively;

[0043] 2) Manually wipe the surface of the plain board treated in step 1) with water-based PUD color wiper, with an amount of 8-12g / m 2 , drying by infrared rays at 70°C for 10 minutes,

[0044] 3) Use a putty roller coater to coat the UV-roller filling putty with an amount of 30-40g / m 2 , 150mJ / cm 2 After UV curing, polish with 240# sandpaper, and paint twice continuously to fill the wooden holes;

[0045] 4) Apply UV-roller sanding primer with a laser roller coater, with an amount of 30-40g / m 2 , leveling for 15 seconds, 80mJ / cm 2 UV semi-curing, the surface is slightly sticky;

[0046] 5) Coat the UV-laser roller coatin...

Embodiment 3

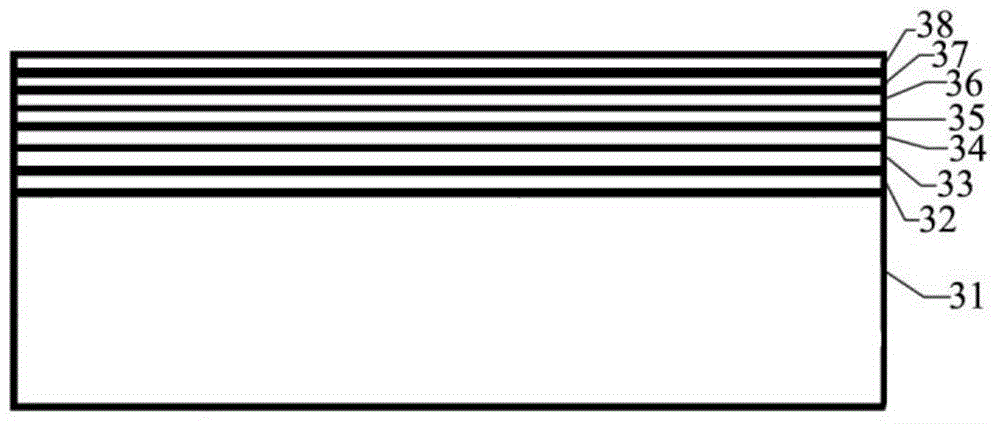

[0052] This embodiment provides a kind of exemplary method for coating planar parts, and its coating steps are identical with embodiment 2, just replace single-component water-based paint with two-component water-based paint, concrete steps are as follows:

[0053] 1) Use 80#, 100#, 120# sandpaper to sand the plain board respectively;

[0054] 2) Manually wipe the surface of the plain board treated in step 1) with water-based PUD color wiper, with an amount of 8-12g / m 2 , drying by infrared rays at 70°C for 10 minutes,

[0055] 3) Use a putty roller coater to coat the UV-roller filling putty with an amount of 30-40g / m 2 , 150mJ / cm 2 After UV curing, polish with 240# sandpaper, and paint twice continuously to fill the wooden holes;

[0056] 4) Apply UV-roller sanding primer with a laser roller coater, with an amount of 30-40g / m 2 , leveling for 15 seconds, 80mJ / cm 2 UV semi-curing, the surface is slightly sticky;

[0057] 5) Coat the UV-laser roller coating primer with a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com