Steel coil standing machine and using method thereof

A technology of vertical coiling machine and steel coil, applied in the direction of workpiece manipulation, etc., can solve the problems of low work efficiency, difficult to install remote control devices, etc., and achieve the effects of improving work efficiency, saving spare parts costs, and reducing the frequency of actions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

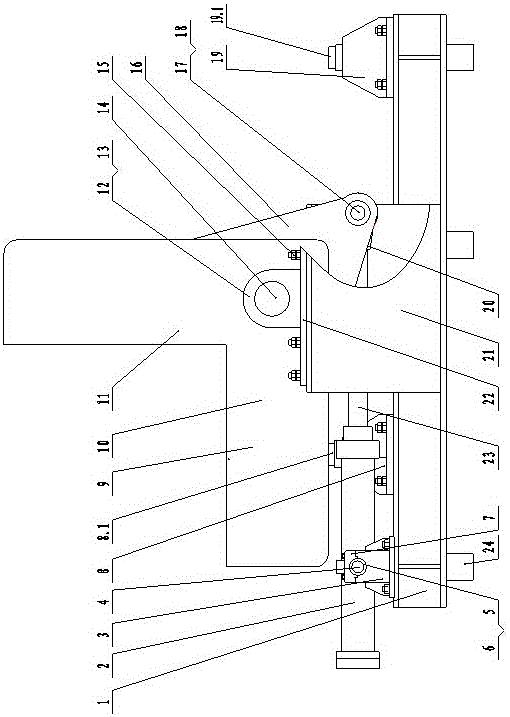

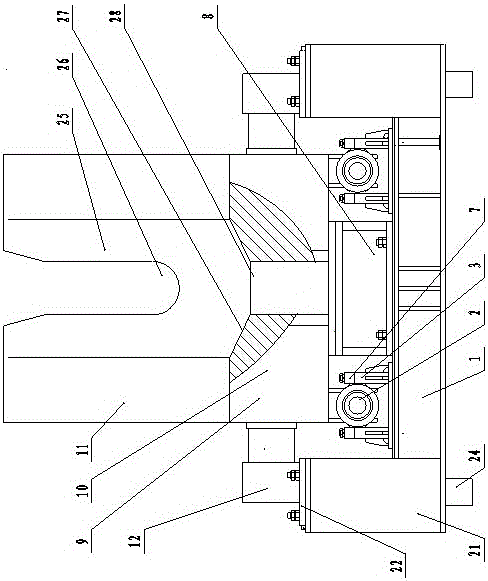

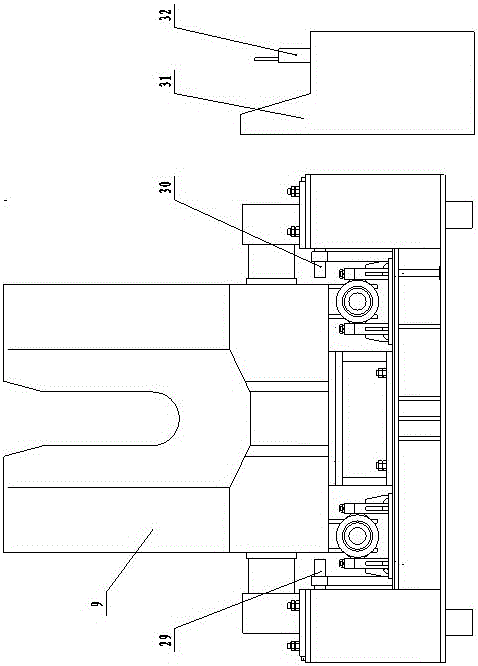

[0038] The embodiment of this device sees figure 1 and figure 2 . It comprises a base 1, an oil cylinder 2, an oil cylinder support seat 3 and an oil cylinder rotating shaft 4 integrated with the oil cylinder. There are two oil cylinders 2, and each oil cylinder 2 has two oil cylinder support seats 3, and the oil cylinder support seats 3 are fastened on the base 1. Between 7, the oil cylinder sliding bearing 6 is installed by the oil cylinder bearing seat 5, and the oil cylinder rotating shaft 4 is installed on the oil cylinder sliding bearing 6;

[0039] It is characterized in that: on the base 1, an overturning frame 9 is installed, and the overturning frame 9 has an overturning vertical frame 11 and an overturning horizontal frame 10 perpendicular to each other (the overturning vertical frame 11 and the overturning horizontal frame 10 form an overturning frame 9). Frame 11 has vertical frame inclined-plane groove 25 sunken in the center, vertical vertical frame U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com