Integrated two-station earing machine for tin plate earing rate detection sample processing

A technology for testing samples and tinplates, used in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of food quality and safety uncertainty, affecting the quality inspection of tinplates, etc., to improve processing efficiency and processing. Accuracy, ensuring food quality and safety, and ensuring the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

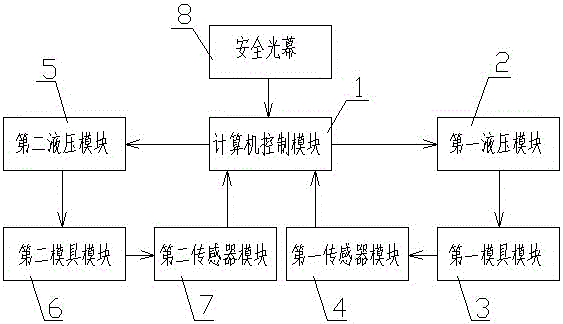

[0019] Example 1 as figure 1 As shown, the integrated double-station earphone used in the present invention for tinplate ear rate detection sample processing includes a computer control module 1, a first hydraulic module 2, a first mold module 3, a first sensor module 4, a second Hydraulic module 5, second mold module 6 and second sensor module 7, said computer control module 1 respectively controls said first hydraulic module 2 and second hydraulic module 5, said first hydraulic module 2 and second hydraulic module 5 respectively drive the first mold module 3 and the second mold module 6 to act, and the first sensor module 4 and the second sensor module 7 respectively detect the die stamping speed of the first mold module 3 and the second mold module 6 , mold clamping force, mold stamping force, stamping deformation depth and the hydraulic pressure of the first hydraulic module 2 and the second hydraulic module 5, the data detected by the first sensor module 3 and the second ...

Embodiment 2

[0020] Example 2, such as figure 1 As shown, on the basis of Embodiment 1, this testing machine also includes a safety light curtain 8, the safety light curtain 8 is arranged on the periphery of the first mold module 3 and the second mold module 6 and the detection signal is transmitted to the Computer control module 1. The safety light curtain is used to ensure the safety of the earphones. When the safety light curtain detects that a foreign object enters its detection area, the first mold module and the second mold module are stopped by the reducer control module.

[0021] Preferably, the safety light curtain 8 includes a light projector and a light receiver, and when the light between the light projector and the light receiver is blocked, the light receiver sends a signal to the computer control module 1 .

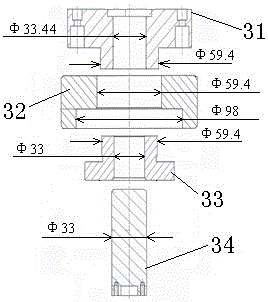

[0022] preferred, such as figure 2 As shown, the first hydraulic module 2 and the second hydraulic module 5 respectively include an oil pump 21, a pressure valve 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com