Robot product shell manufacturing method adopting nitrogen forming

A manufacturing method and robot technology, applied in the field of robot product manufacturing and processing, can solve problems such as increasing process costs, achieve the effects of optimizing product process, increasing strength and dimensional stability, and improving product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

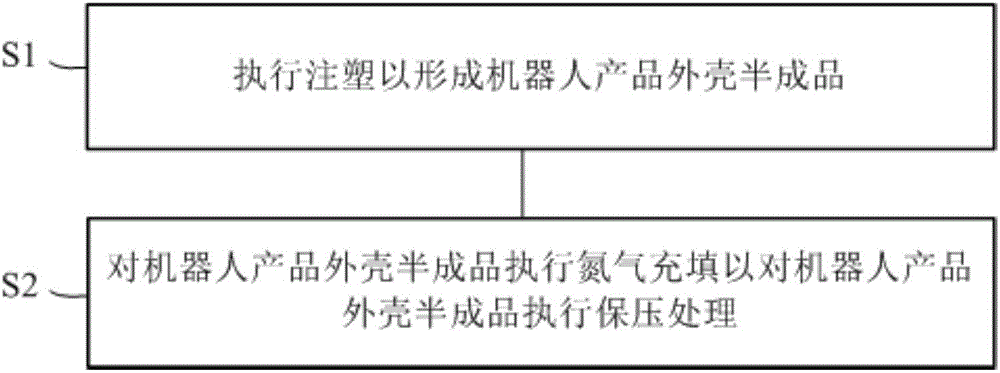

[0018] figure 2 It is a flow chart of a method for manufacturing a robot product shell using nitrogen forming according to a preferred embodiment of the present invention.

[0019] Such as figure 2 As shown, the manufacturing method of the robot product shell adopting nitrogen forming according to the preferred embodiment of the present invention comprises:

[0020] First step S1: performing injection molding to form a semi-finished robot product shell;

[0021] Second step S2: Nitrogen filling is performed on the semi-finished product casing of the robot product to perform pressure-holding treatment on the semi-finished product casing of the robot product.

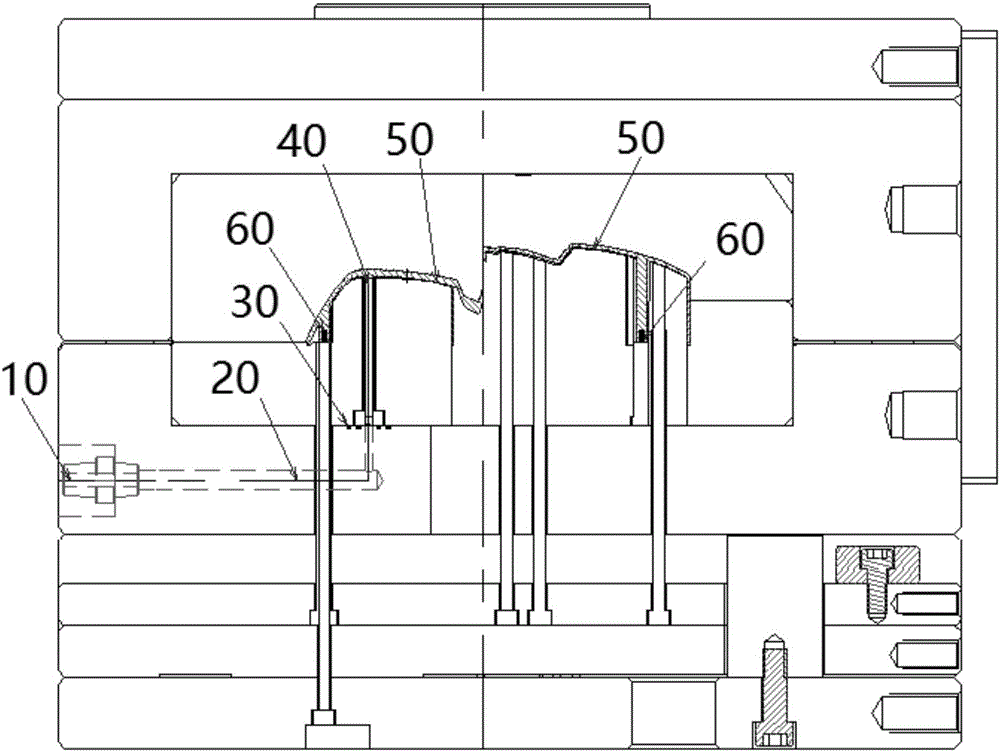

[0022] Specifically, such as image 3 As shown, in the second step S2, in the nitrogen filling equipment, the nitrogen connector 10 is connected to the nitrogen hole 20, the nitrogen hole 20 is connected to the nitrogen needle 40 through the O-ring 30, and the nitrogen needle 40 is pierced into the shell of the robot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com