Welding electrode coating device

A technology of coating device and welding rod, which is applied in the directions of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of low wages for packaging workers, difficulties in recruiting workers for packaging positions, and increased labor costs, so as to ensure product appearance and quality. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below through specific examples.

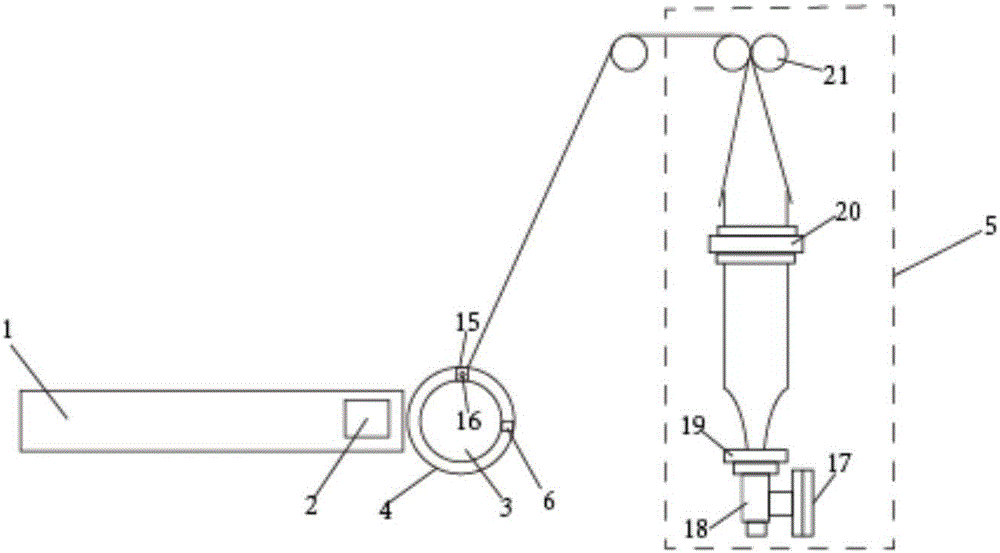

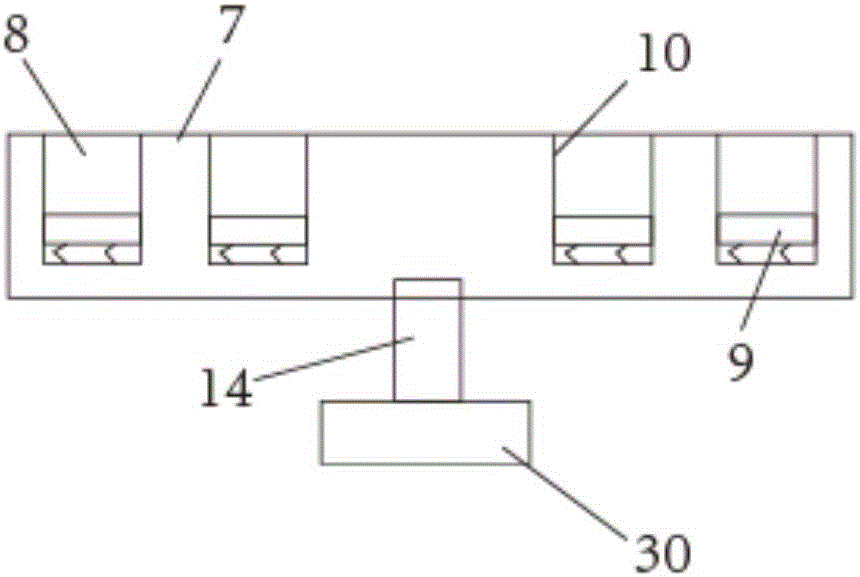

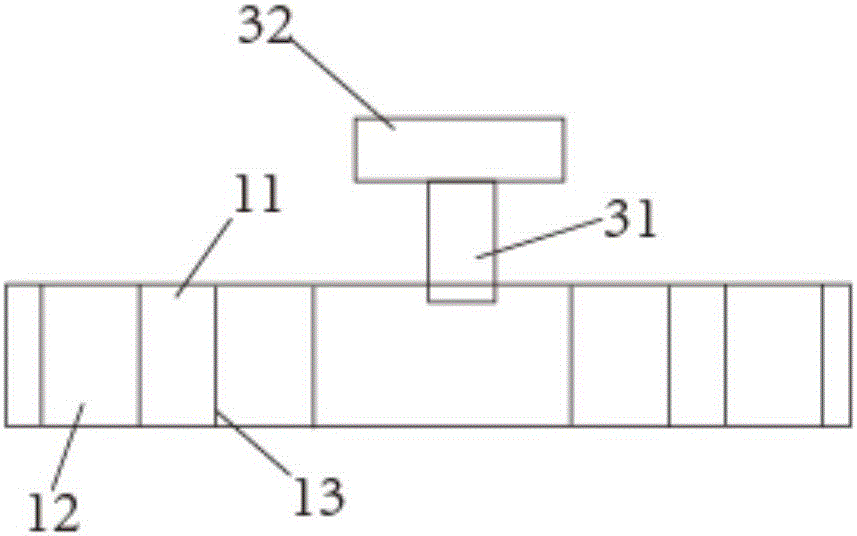

[0018] Such as Figure 1 to Figure 4 As shown, among them, 1 is the welding rod conveying device, 2 is the welding rod grasping device, 3 is the welding rod fixing device, 4 is the welding rod coating device, 5 is the film heating device, 6 is the sealing and cutting device, 7 is the base body, 8 is the welding rod Placement slot, 9 is the buffer in the slot, 10 is the edge buffer, 11 is the positioning plate, 12 is the electrode guide hole, 13 is the guide buffer, 14 is the base rotation axis, 15 is the coating base, 16 is the film fixing rod , 17 is the primary heating device, 18 is the extrusion device, 19 is the film stretching device, 20 is the secondary heating device, 21 is the double-layer merging device, 22 is the welding rod grabbing part, 23 is the electromagnetic adsorption device, 24 is the electromagnetic Adsorption power supply, 25 is grabbing gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com