Automatic winding device used for producing non-woven fabrics

A winding device, non-woven technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc. Increase the working time of operators and other problems to achieve the effect of improving the winding effect, increasing the operation stability and reducing the labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

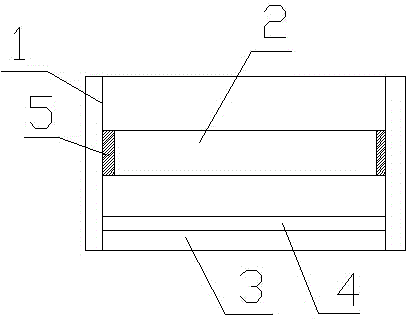

[0012] An automatic winding device for producing non-woven fabrics, comprising a frame 1 and a reel 2, the frame 1 is provided with a reel 2, the reel 2 is located in the middle of the frame 1, and the rear side of the frame 1 is provided with a motor, The motor drives the reel to move. There is a conveyor belt on the motor, and a synchronous shaft next to the reel. Drive the cutter to move up and down. There is a base 3 under the frame 1. There is a transmission gap between the base 3 and the reel. The upper and lower distances of the transmission gap are adjustable. On the outside, the reel 2 has a cylindrical structure, and there are gap adjustment devices 5 on both sides of the reel 2. The gap adjustment device 5 is controlled by a cylinder. There is a control circuit next to the cylinder, and a control valve is provided on the control circuit. The control valve is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com