Treatment Technology of Wastewater from Alkali Pretreatment of Polyester Fabric

A polyester fabric and wastewater technology, which is applied in biological water/sewage treatment, textile industry wastewater treatment, multi-stage water treatment, etc. , The effect of reducing the generation of waste residue and salt concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

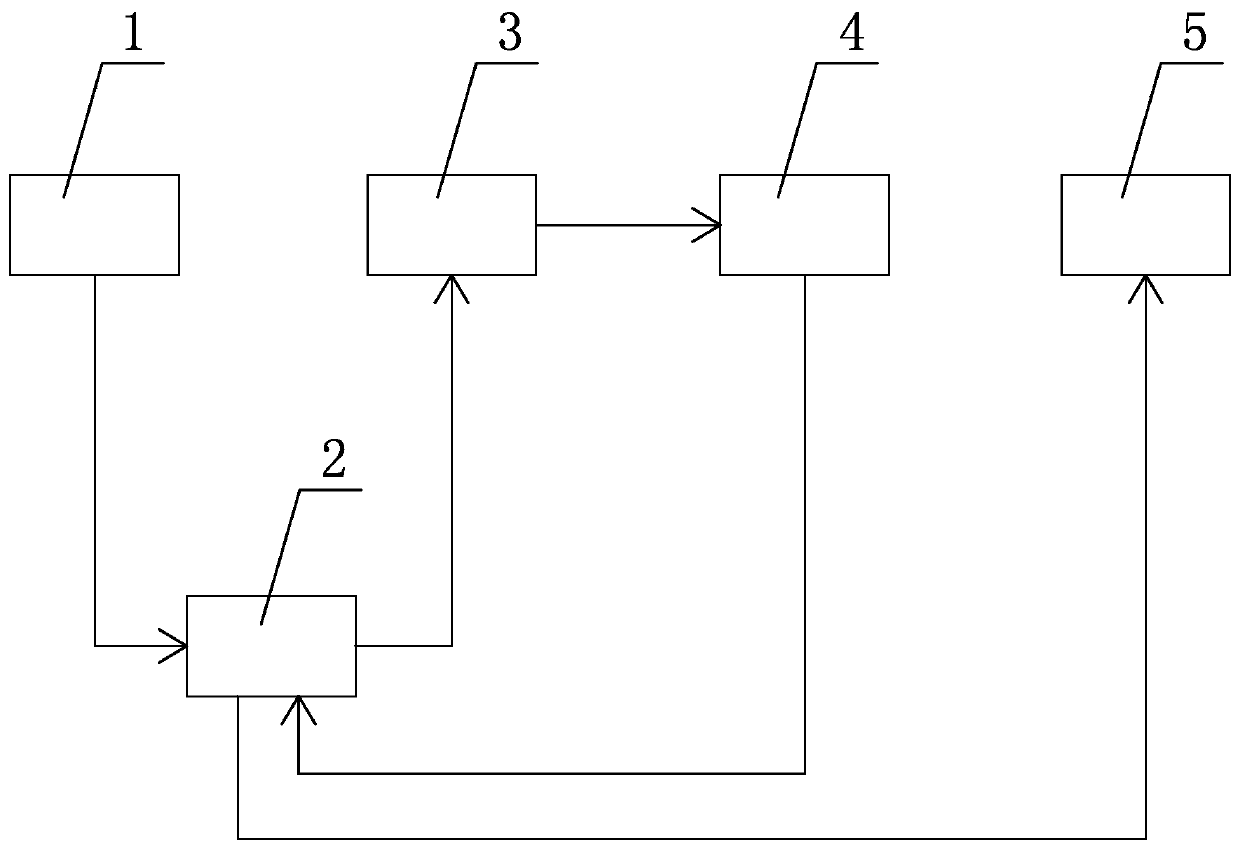

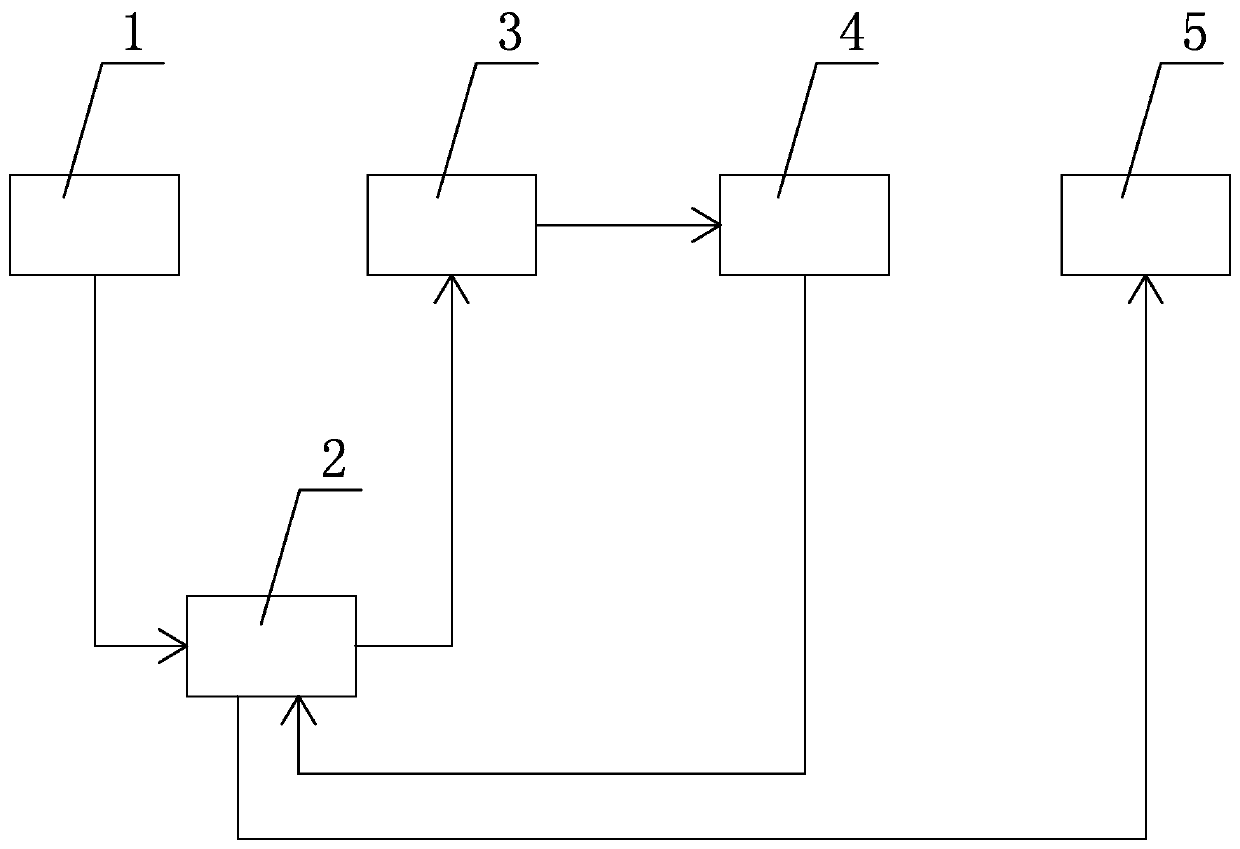

[0016] combine figure 1 Shown, the treatment process of polyester fabric alkali pretreatment waste water of the present invention comprises the following steps:

[0017] (1) Transport the polyester fabric alkali pretreatment wastewater 1 with a pH value above 14 to the alkali-absorbing resin device 2, and the alkali-absorbing resin layer in the alkali-absorbing resin device 2 absorbs alkali, and firstly absorbs alkali through the alkali-absorbing resin layer The pH value of the waste water is 6, and with the gradual saturation of the alkali-absorbing resin layer, the pH value of the wastewater after the alkali-absorbing resin layer absorbs alkali gradually increases; when the pH value of the wastewater after alkali-absorbing resin layer reaches 12 or more , the alkali absorption process of the alkali-absorbing resin layer ends, stop the action of continuing to transport the polyester fabric alkali pretreatment wastewater 1 to the alkali-absorbing resin device 2, and discharge ...

Embodiment 2

[0023] combine figure 1 Shown, the treatment process of polyester fabric alkali pretreatment waste water of the present invention comprises the following steps:

[0024] (1) Transport the polyester fabric alkali pretreatment wastewater 1 with a pH value above 14 to the alkali-absorbing resin device 2, and the alkali-absorbing resin layer in the alkali-absorbing resin device 2 absorbs alkali, and firstly absorbs alkali through the alkali-absorbing resin layer The pH value of the waste water is 6, and with the gradual saturation of the alkali-absorbing resin layer, the pH value of the wastewater after the alkali-absorbing resin layer absorbs alkali gradually increases; when the pH value of the wastewater after alkali-absorbing resin layer reaches 12 or more , the alkali absorption process of the alkali-absorbing resin layer ends, stop the action of continuing to transport the polyester fabric alkali pretreatment wastewater 1 to the alkali-absorbing resin device 2, and discharge ...

Embodiment 3

[0030] combine figure 1 Shown, the treatment process of polyester fabric alkali pretreatment waste water of the present invention comprises the following steps:

[0031] (1) Transport the polyester fabric alkali pretreatment wastewater 1 with a pH value above 14 to the alkali-absorbing resin device 2, and the alkali-absorbing resin layer in the alkali-absorbing resin device 2 absorbs alkali, and firstly absorbs alkali through the alkali-absorbing resin layer The pH value of the waste water is 6, and with the gradual saturation of the alkali-absorbing resin layer, the pH value of the wastewater after the alkali-absorbing resin layer absorbs alkali gradually increases; when the pH value of the wastewater after alkali-absorbing resin layer reaches 12 or more , the alkali absorption process of the alkali-absorbing resin layer ends, stop the action of continuing to transport the polyester fabric alkali pretreatment wastewater 1 to the alkali-absorbing resin device 2, and discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com